Method for quickly verifying vehicle frame

It is a skeleton and fast technology, which is applied in vehicle suspension/shock absorbing mechanism testing, mechanical component testing, machine/structural component testing, etc. It can solve problems such as high cost and long cycle time, and achieve cost savings, improved verification strength, and The effect of shortening the verification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

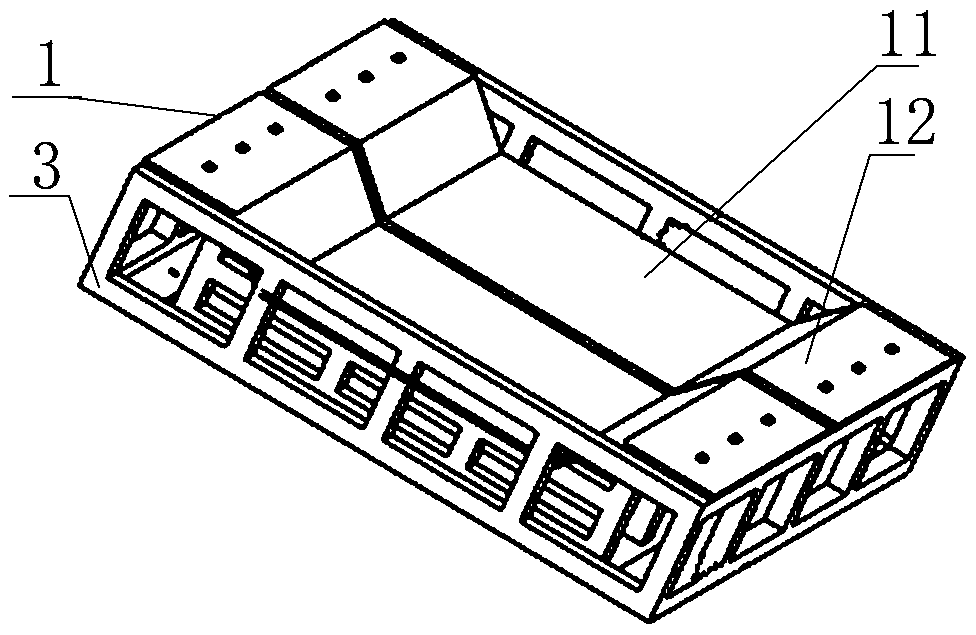

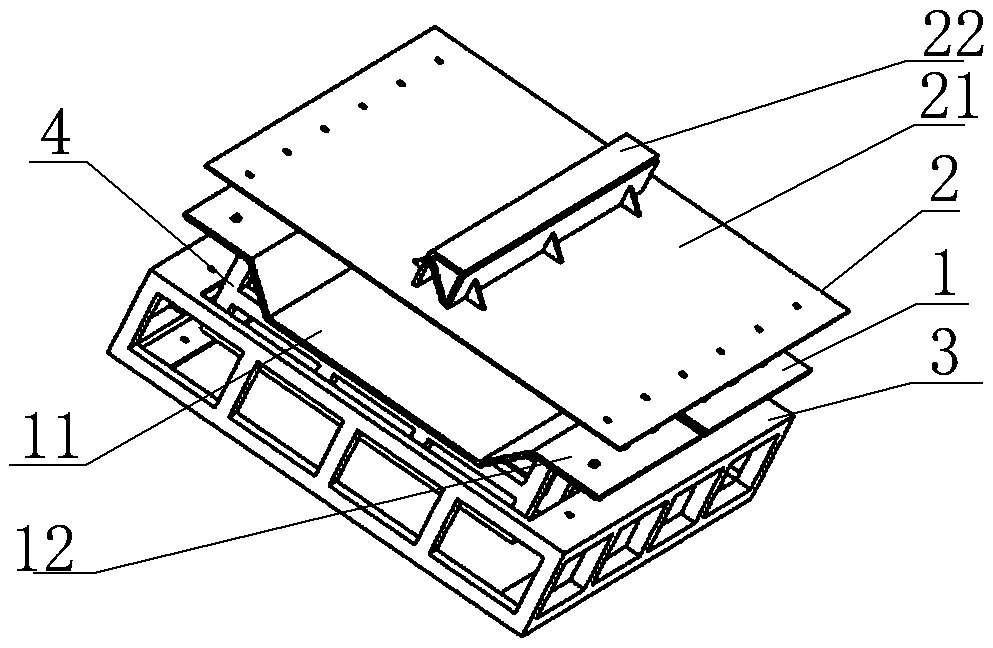

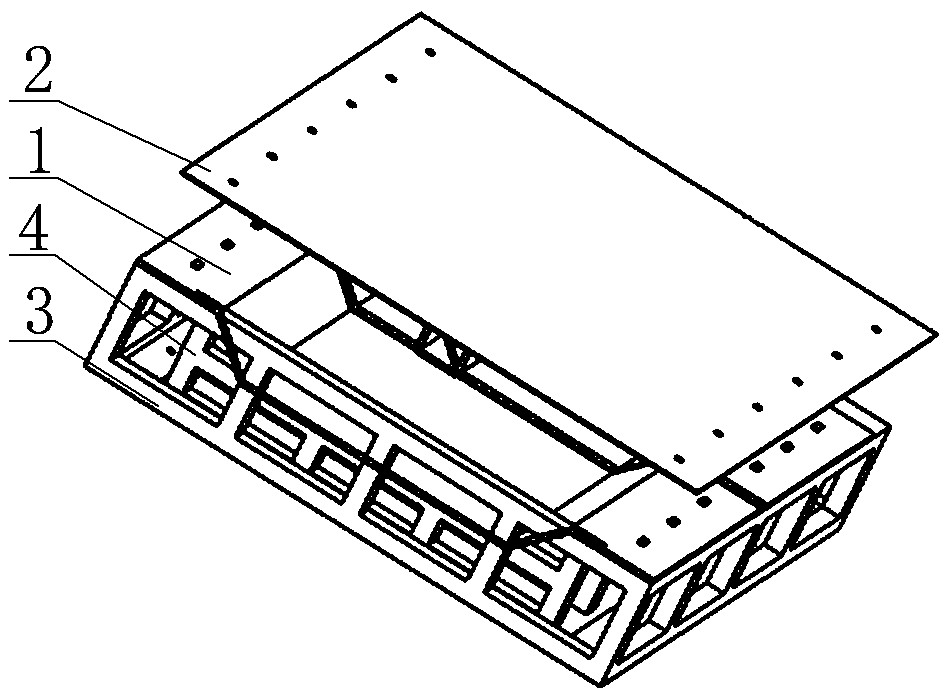

[0021] The specific embodiment of the method for rapid verification of the vehicle skeleton in the present invention, such as Figure 1-3 As shown in Fig. 1, pits and / or bumps are set on the test track to simulate the impact conditions on the real road surface, and the rapid verification of the vehicle skeleton is realized by testing the stress peaks of the impact conditions.

[0022] In this embodiment, a foundation pit is set on the test track, and a support frame 3 is set in the foundation pit. The device also includes a pit module 1 with a concave portion 11 for simulating road pits and / or a pit module 1 with a boss for simulating road surfaces. The raised boss module 2, the top of the support frame 3 has a connection structure for detachable fixing with the pit module 1 and / or the boss module 2, and the support frame 3 includes a structure for accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com