Workpiece quality inspection method and its device, medium, numerical control system and quality inspection system

A workpiece and quality inspection technology, which is applied in general control systems, control/adjustment systems, comprehensive factory control, etc., can solve the problems of high skill requirements for operators, affecting the processing efficiency of machine tools, and heavy workload of operators, so as to reduce Operating procedures, avoiding false reporting incidents, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] As mentioned in the background, the processing efficiency of existing machine tools needs to be improved.

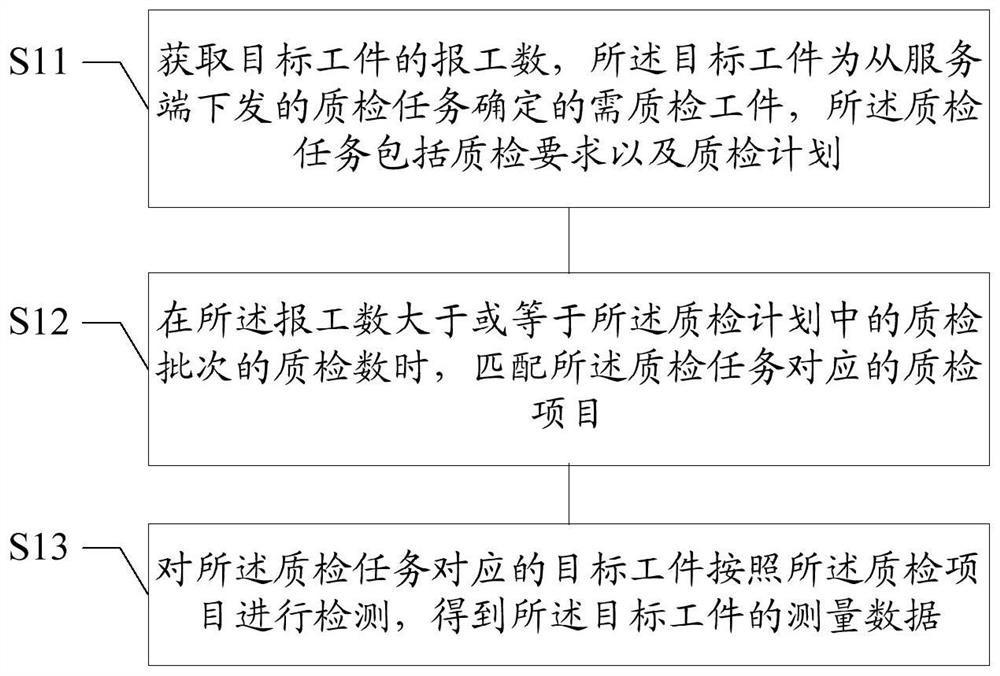

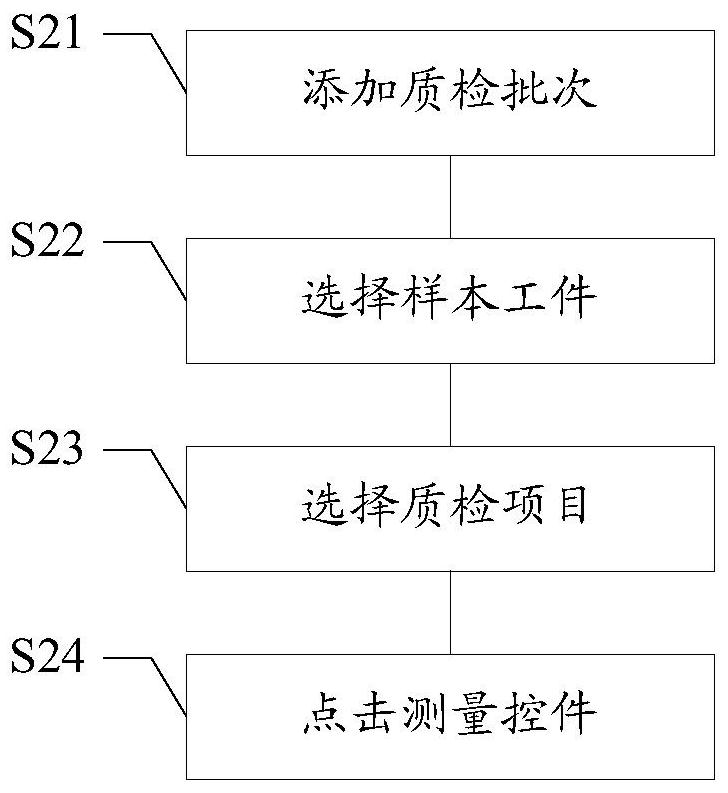

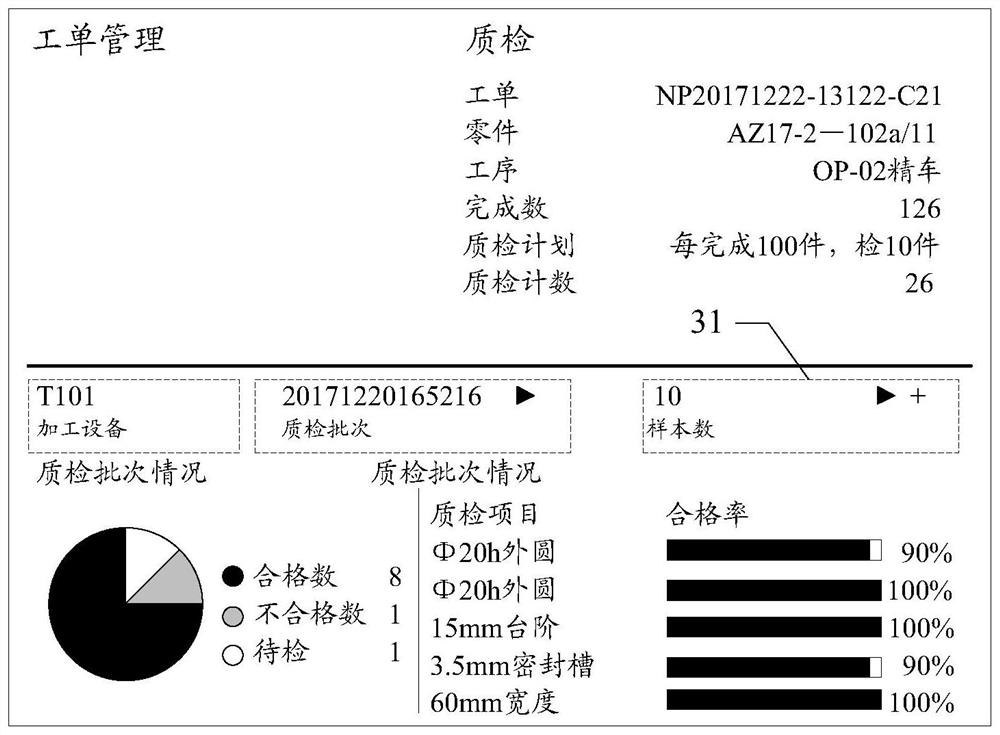

[0048] In the embodiment of the present invention, by obtaining the number of work reports of the target workpiece, when the number of work reports is greater than or equal to the number of quality inspections of each quality inspection batch confirmed in the quality inspection plan, the corresponding quality inspection task is matched. the quality inspection items, the target workpiece corresponding to the quality inspection task is detected according to the quality inspection items, and the measurement data of the target workpiece is obtained. In this way, the number of job reports for the workpiece can be automatically obtained without the need for the operator to manually input the number of job reports, so the operator's operating procedures can be reduced, and the operating burden of the operator can be reduced; at the same time, since the operator does not n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com