Coil device

A coil device and coil technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor components, etc. The effect of ensuring insulation and ensuring insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

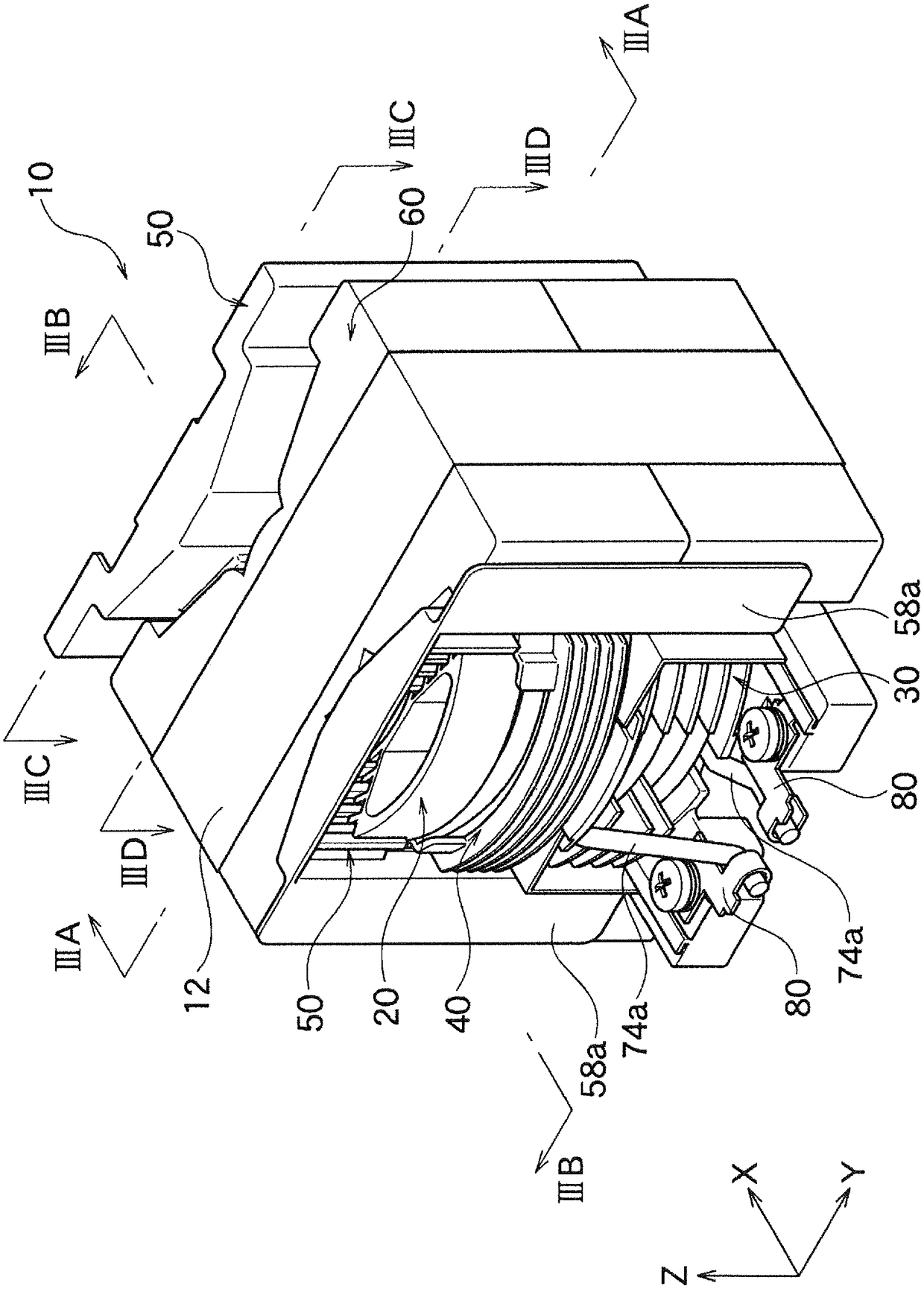

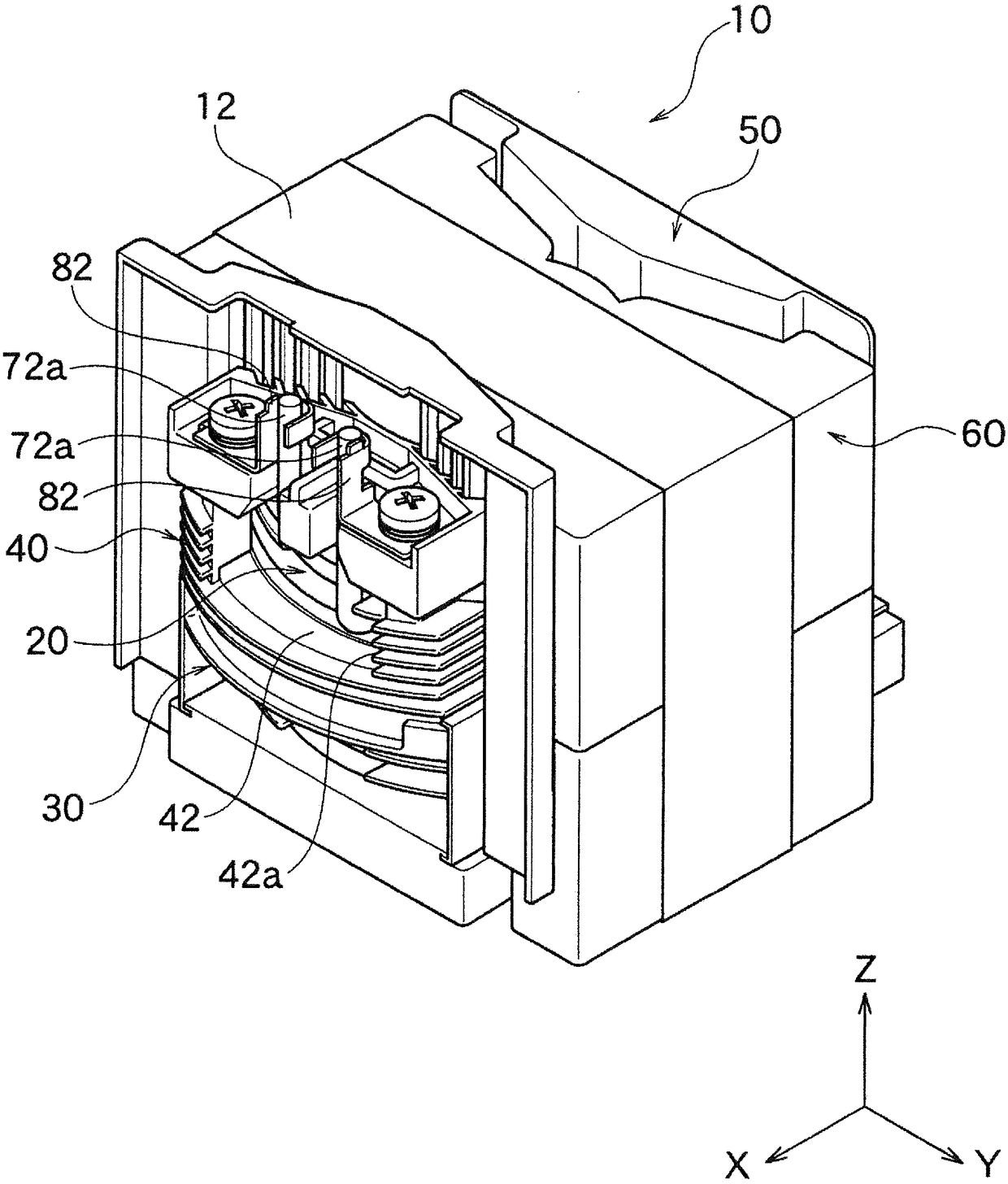

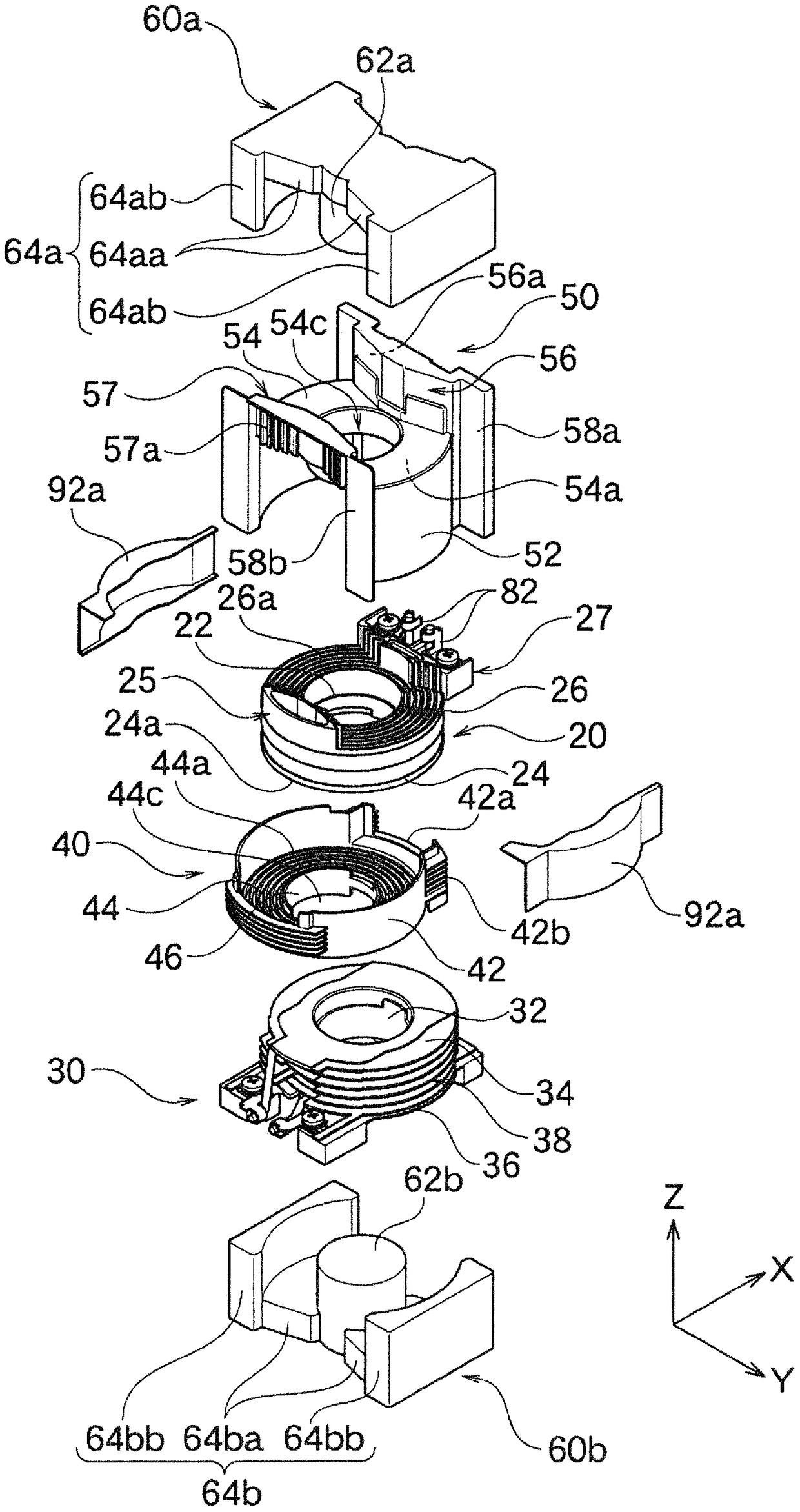

[0085] Figure 1A It is a perspective view of the coil device 10 which concerns on one Embodiment of this invention. The coil device 10 has a first bobbin 20 , a second bobbin 30 , a central cover member 40 , an end cover member 50 , and a core 60 . In addition, the insulating tape 12 is wound on the surface of the core 60 .

[0086] In addition, regarding the coil device 10 according to the embodiment, as Figure 1A As shown, the direction perpendicular to the installation surface on which the coil device 10 is installed is set as the Z-axis direction, and the direction parallel to the installation surface is set as figure 2 The direction connecting the two side leg portions 64ab and 64bb of the core 60 passing through the first frame 20 and the second frame 30 on both sides is referred to as the Y-axis direction, and the direction perpendicular to the Z-axis direction and the Y-axis direction is referred to as The X-axis direction will be described. In addition, the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com