Cotton hybrid seed production method and pollination tube

A technology of hybrid seed production and pollination tube, which is applied in the agricultural field, can solve the problems of easy damage to stigma and ovary, different inner diameters, and hard texture, so as to improve seed production efficiency and operability, reduce seed production costs, and reduce costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

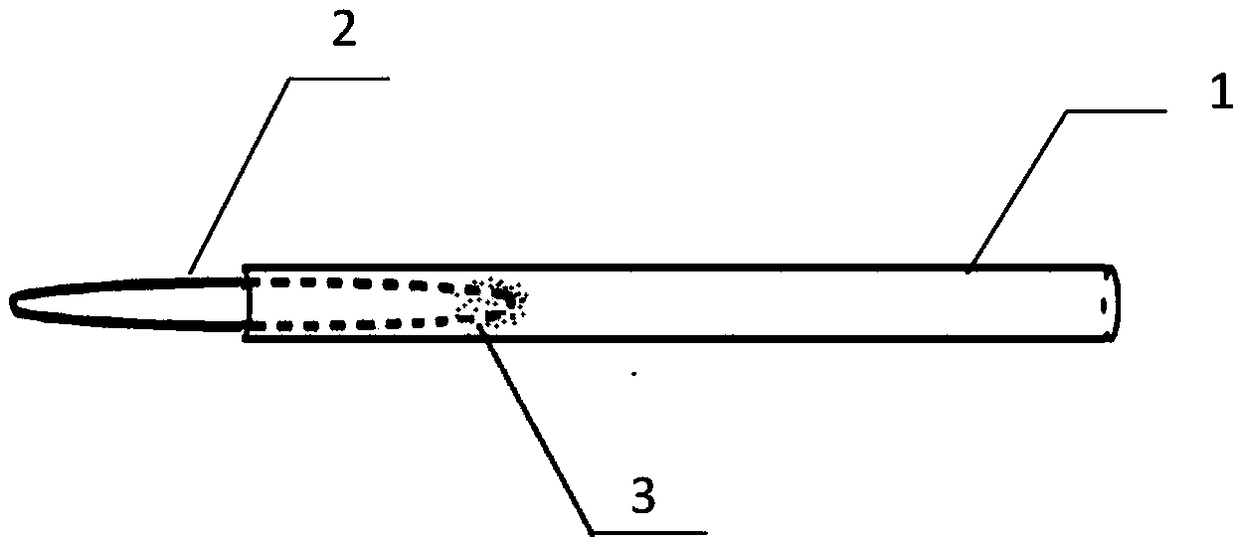

[0037] Embodiment 1, cotton hybrid seed production pollination tube and its application

[0038] 1. Making pollination tubes for cotton hybrid seed production

[0039] Cotton hybrid seed production pollination tube, comprising a hollow wax tube 1, one end of the wax tube 1 is open, the other end is closed with a soft material 2 matching the inner diameter of the wax tube 1, and the soft material 2 is located on the One end of wax tube 1 inside is stained with cotton male parent pollen 3. The inner diameter of the wax tube 1 is 5 mm; the length of the wax tube 1 is 2 cm. The soft material 2 is a sliver made of cotton twisted into strips. The diameter of the sliver is 4mm-5mm.

[0040] The wax tube 1 is manufactured as follows: paper is rolled into a tube with an inner diameter of 5 mm, immersed in melted paraffin, picked up and dried, and cut into a tube with a length of 2.0 cm.

[0041] The production method of the pollination tube for cotton hybrid seed production: take a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com