Combined part assembly depth detection method

A technology of depth detection and assembly, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of difficulty in ensuring the consistency of the assembly quality of the sealing head and the sealing head sheath, the reliability of the detection quality is not high, and the detection efficiency is low. and other problems, to achieve the effect of reducing manual detection intervention, avoiding uncertainty interference, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

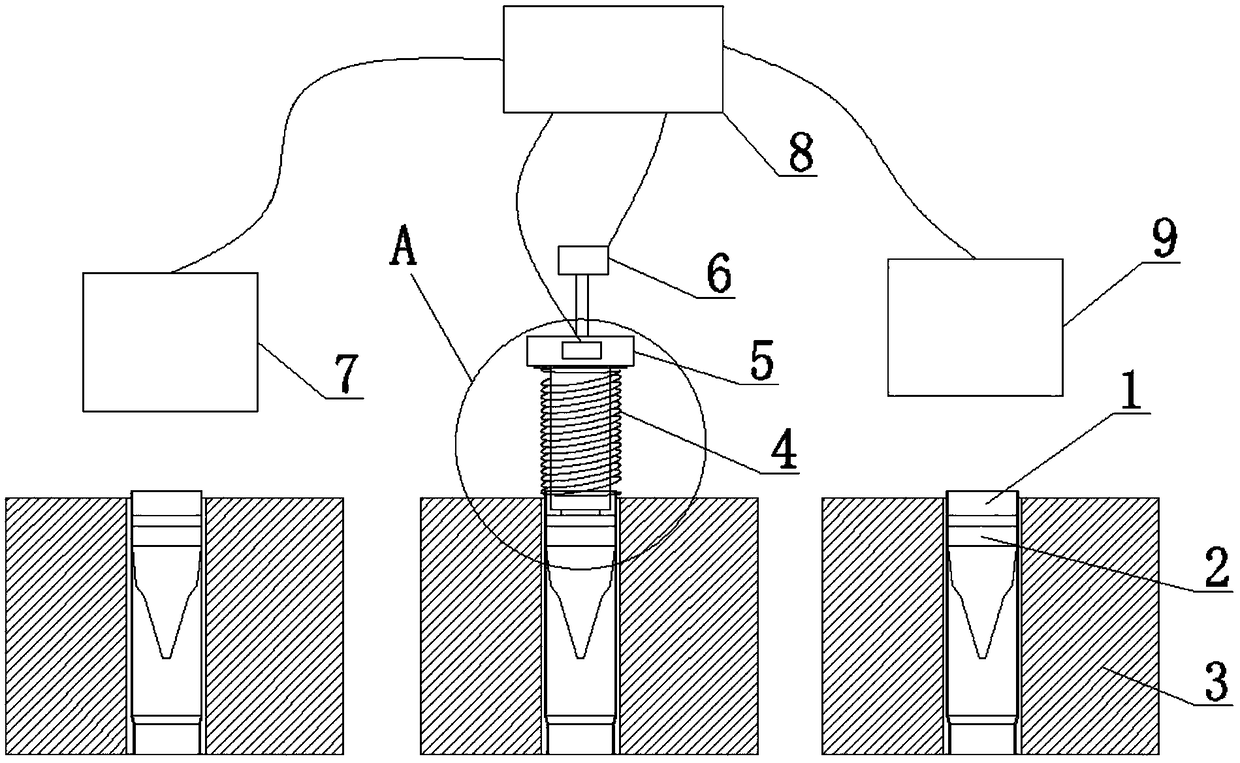

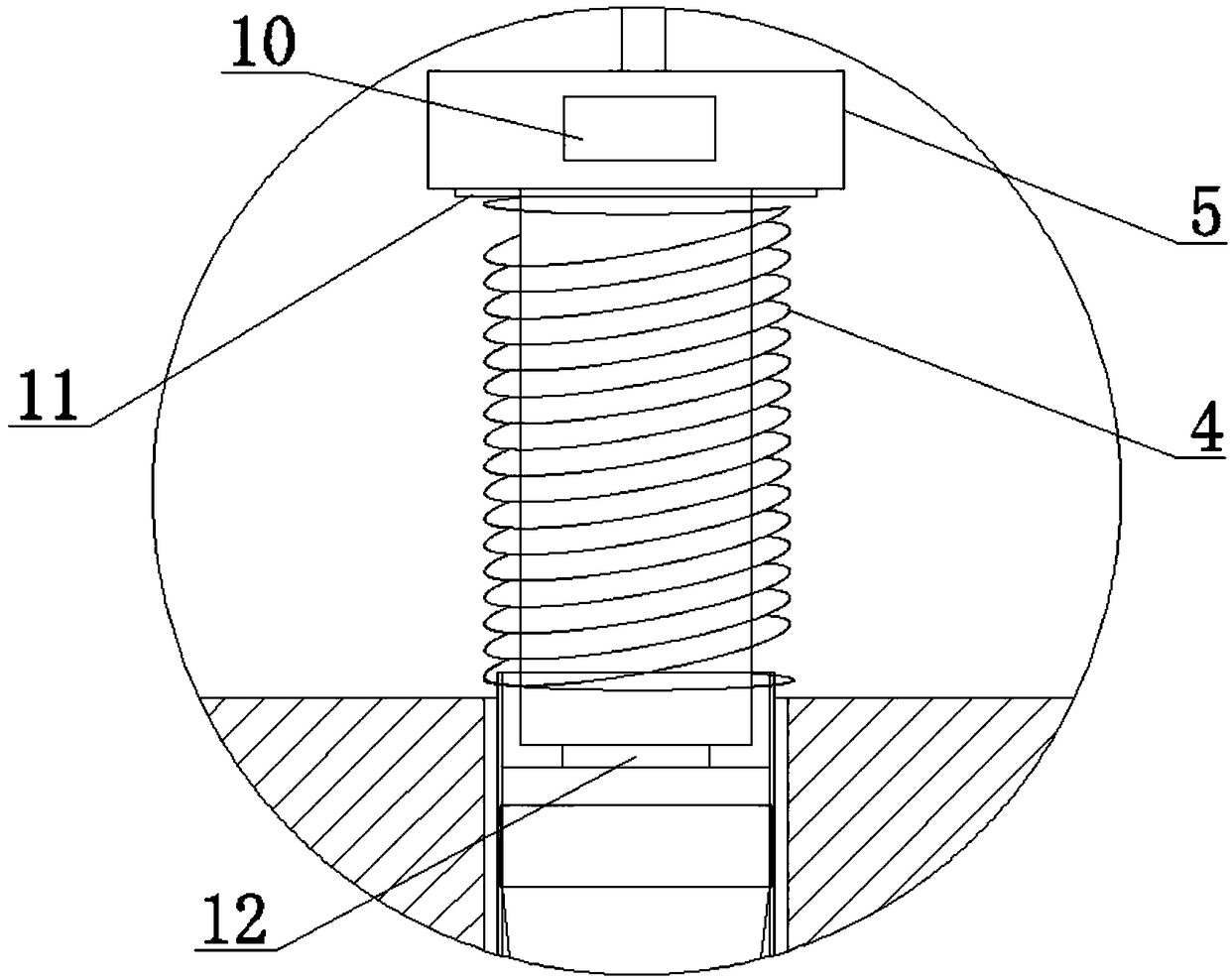

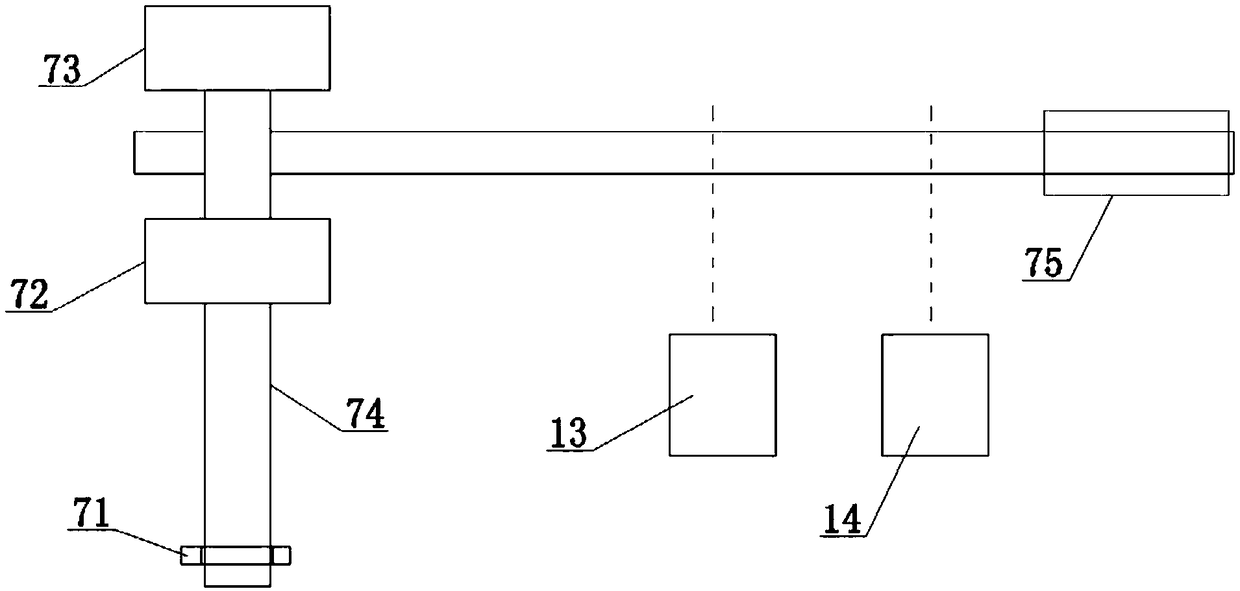

[0024] like figure 1 As shown, in the process of assembling the tubular fitting 1 and the cylindrical fitting 2 into an assembly, it is necessary to detect the assembly depth of the cylindrical fitting 2 inserted into the cavity of the tubular fitting 1 . When specifically detecting the assembly depth of the assembly, it includes a detection rod 5, a first cylinder 6, a take-out device 7, a controller 8, and a press-in device 9. The detection rod 5 preferably adopts a T-shaped structural member, and the detection rod 5 A pressure sensor 11 and a position sensor 12 are respectively installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com