A kind of nano chitin material and its preparation method and application

A nano-chitin and chitin technology, applied in the field of materials, can solve the problems of consumption of large hydrochloric acid acid waste liquid, negative impact on the environment, etc., and achieve the effects of reducing pollution, reducing emissions, and highly efficient enzyme immobilization carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

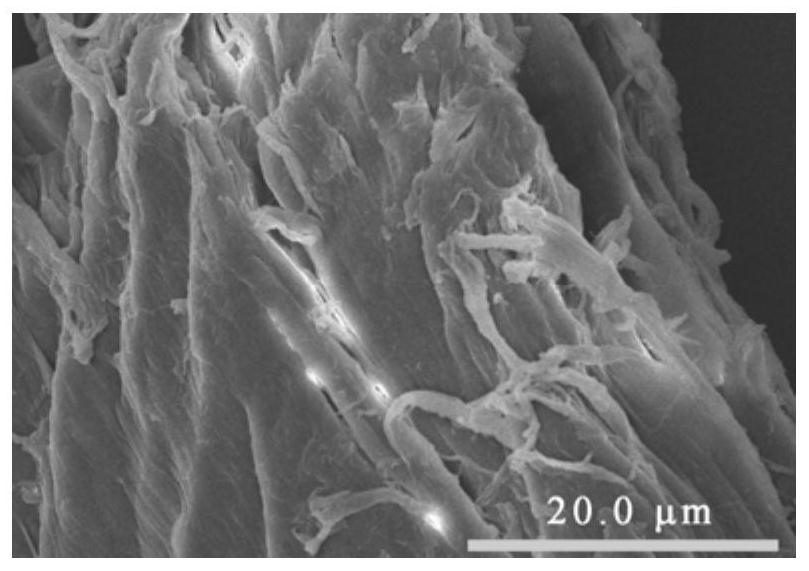

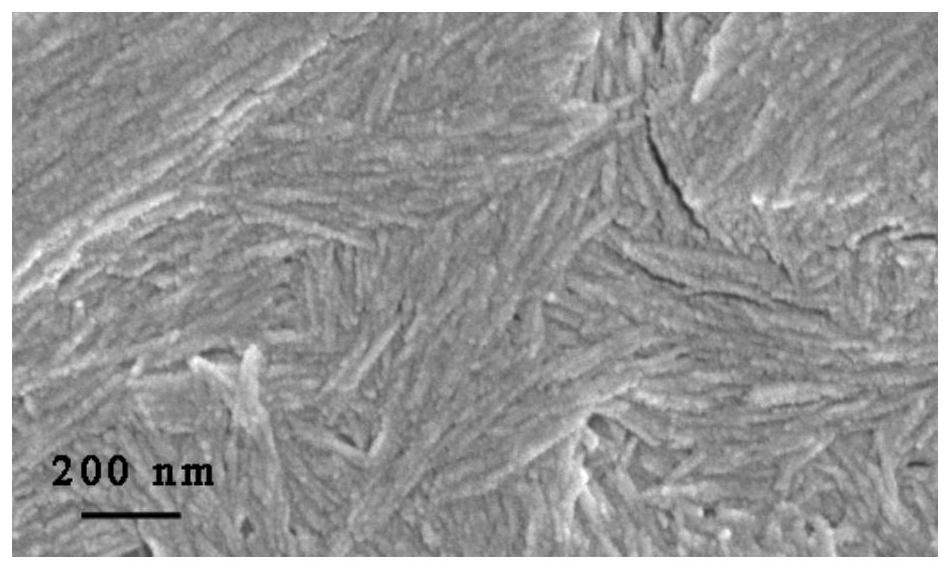

Embodiment 1

[0033] Weigh the chitin raw material and p-toluenesulfonic acid-choline chloride with a mass ratio of 1:20, add the chitin raw material to p-toluenesulfonic acid-choline chloride, and continuously mix the mixed samples at a temperature of 95°C Stir the reaction for 30 minutes to obtain the chitin raw material / p-toluenesulfonic acid-choline chloride reaction mixture. Under the condition of continuous stirring, the reaction mixture was added to ethanol (the mass ratio of the two was 1:20), and the mixed solution was centrifuged at 4000rpm for 10min to collect the centrifuged solid part, and then 50mL ethanol Mix with the solid part, centrifuge the mixed solution for 5 minutes under the condition of 4000rpm, and repeat this step once more to obtain the nanoscale chitin product. After the reaction, the p-toluenesulfonic acid-choline chloride was separated from the ethanol solution by rotary evaporation, and the p-toluenesulfonic acid-choline chloride mixed solution was recovered. ...

Embodiment 2

[0039] Weigh the chitin raw material and p-toluenesulfonic acid-choline chloride with a mass ratio of 4:10, add the chitin raw material to p-toluenesulfonic acid-choline chloride, and continuously mix the mixed samples at a temperature of 80°C Stir the reaction for 60 minutes to obtain the chitin raw material / p-toluenesulfonic acid-choline chloride reaction mixture. Under the condition of continuous stirring, the reaction mixture was added to ethanol (the mass ratio of the two was 1:10), and the mixed solution was centrifuged at 4000rpm for 10min, and the centrifuged solid part was collected, and then mixed with 50mL ethanol Mix with the solid part, centrifuge the mixed solution for 5 minutes under the condition of 4000rpm, and repeat this step once more to obtain the nanoscale chitin product. After the reaction, the p-toluenesulfonic acid-choline chloride was separated from the ethanol solution by rotary evaporation, and the p-toluenesulfonic acid-choline chloride mixed solut...

Embodiment 3

[0041]Weigh the chitin raw material and p-toluenesulfonic acid-choline chloride with a mass ratio of 1:100000, add the chitin raw material to p-toluenesulfonic acid-choline chloride, and continuously mix the mixed samples at a temperature of 100°C Stir the reaction for 30 minutes to obtain the chitin raw material / p-toluenesulfonic acid-choline chloride reaction mixture. Under the condition of continuous stirring, the reaction mixture was added to ethanol (the mass ratio of the two was 1:25), and the mixed solution was centrifuged at 4000rpm for 10min, the centrifuged solid part was collected, and then mixed with 50mL ethanol Mix with the solid part, centrifuge the mixed solution for 5 minutes under the condition of 4000rpm, and repeat this step once more to obtain the nanoscale chitin product. After the reaction, the p-toluenesulfonic acid-choline chloride was separated from the ethanol solution by rotary evaporation, and the p-toluenesulfonic acid-choline chloride mixed solut...

PUM

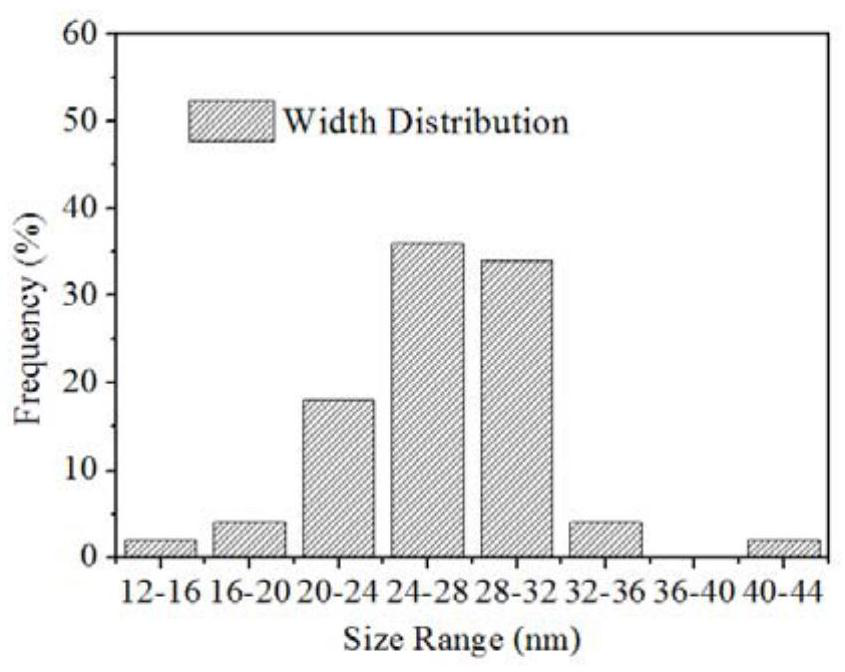

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap