Isopycnic cotton preparation method and isopycnic cotton

A technology of equal density and cotton material, which is applied to the preparation of equal density cotton and the field of equal density cotton, can solve the problems of different densities, complicated preparation methods, and complicated steps, and achieve the effect of uniform density and favorable promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

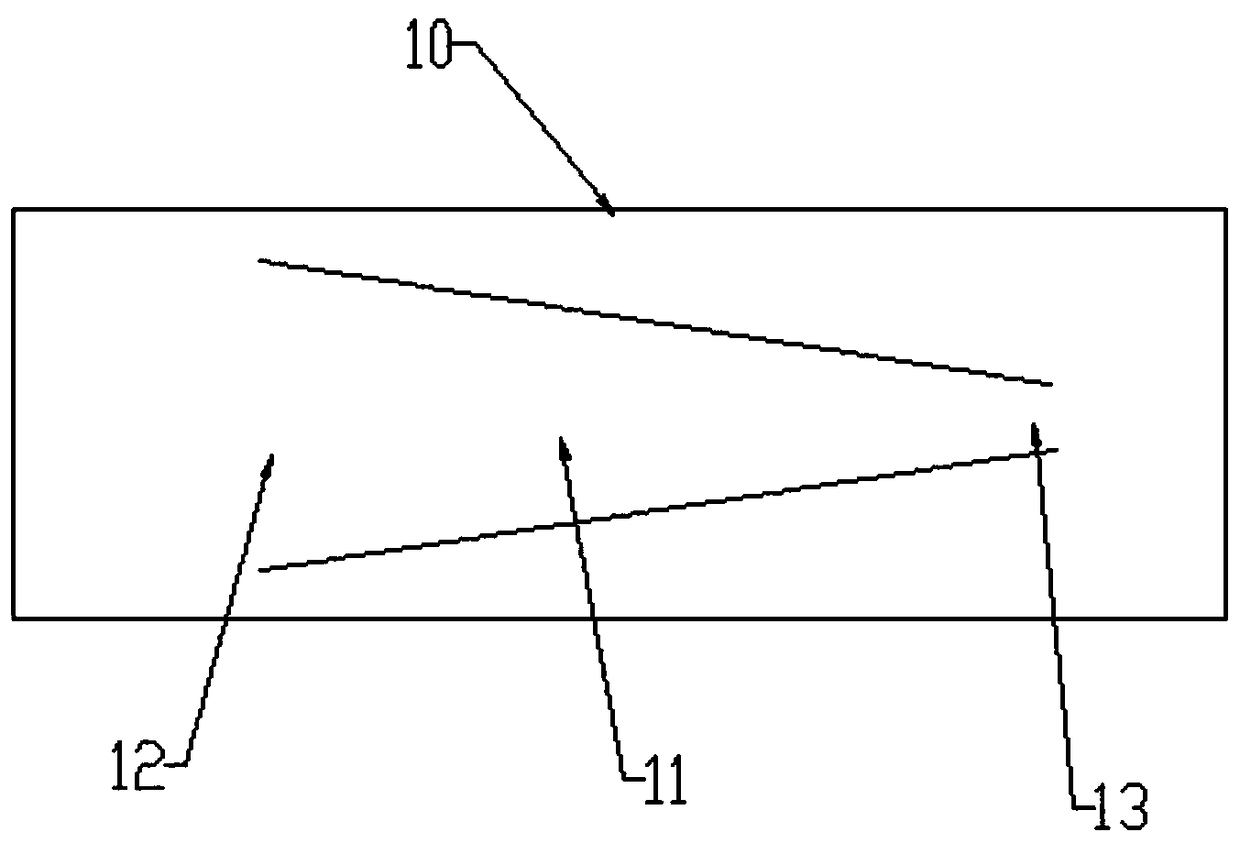

[0025] like Figure 1-3 Shown, a kind of preparation method of equal density cotton comprises the following steps:

[0026] Cotton material production steps: the raw material is firstly opened by the opening device, carded by the carding machine, and then entered into the flat laying machine for flat laying, and then enters the oven for drying after cutting, and then is discharged through the outlet of the oven. Cotton material is formed; wherein, the raw material includes polyester chemical fiber, fiber and low-melting cotton; the opening device includes a pre-opener and a main feeder, and specifically, the raw material is first pre-opened by a pre-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com