Chemical fiber face brick and manufacturing method thereof

A manufacturing method and chemical fiber technology, applied in non-woven fabrics, textiles, papermaking, knotting, etc., can solve the problems of no effect, single function, etc., and achieve the effect of low cost, simple process, and good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

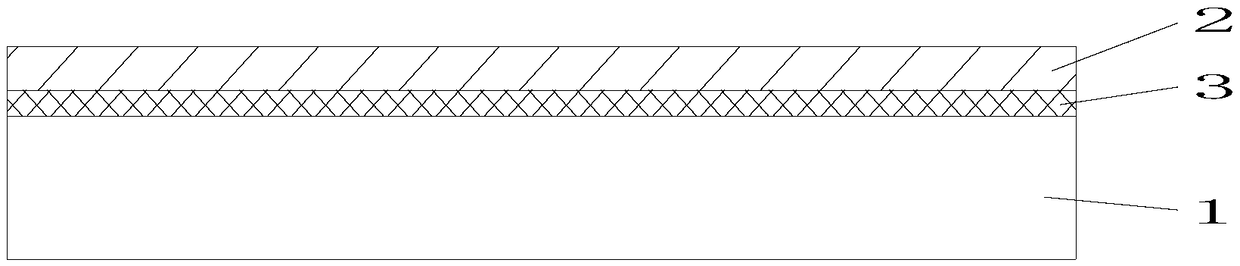

[0018] A chemical fiber facing brick, including polyester 1 and flax 2, but not limited to flax, and also includes functional fibers such as bamboo charcoal fiber, flame-retardant fiber, antibacterial and anti-mite fiber, and chemical fiber hot-melt bonding cotton 3 is arranged between polyester 1 and flax 2 Fixed connection, polyester has a weight of 10g per 1 cubic centimeter.

[0019] It also includes a method for manufacturing the chemical fiber facing brick, which sequentially includes stirring, laying, bonding and pressing, and the specific steps are as follows:

[0020] Stirring: uniformly mix chemical fiber hot-melt bonded cotton and polyester through a stirrer to form a polyester mixture, and uniformly mix chemical fiber hot-melt bonded cotton and flax through a stirrer to form a flax mixture;

[0021] Laying: Carding the polyester mixture and the flax mixture through a carding machine respectively, laying the web layer by layer after carding, placing the flax mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com