Full-automatic building ground compaction robot

A fully automatic and robotic technology, applied in construction, infrastructure engineering, soil protection, etc., can solve the problems of deviation of work direction, increase labor intensity, increase operation difficulty, etc., achieve stable walking route, increase company efficiency, reduce The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

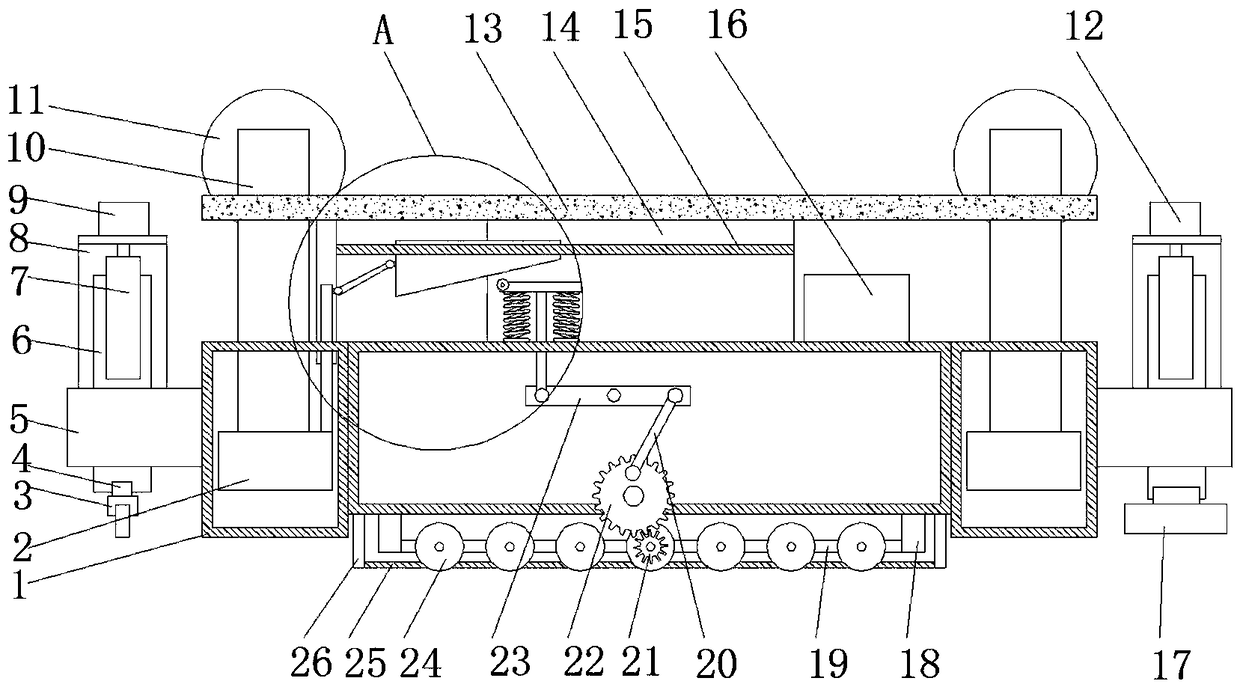

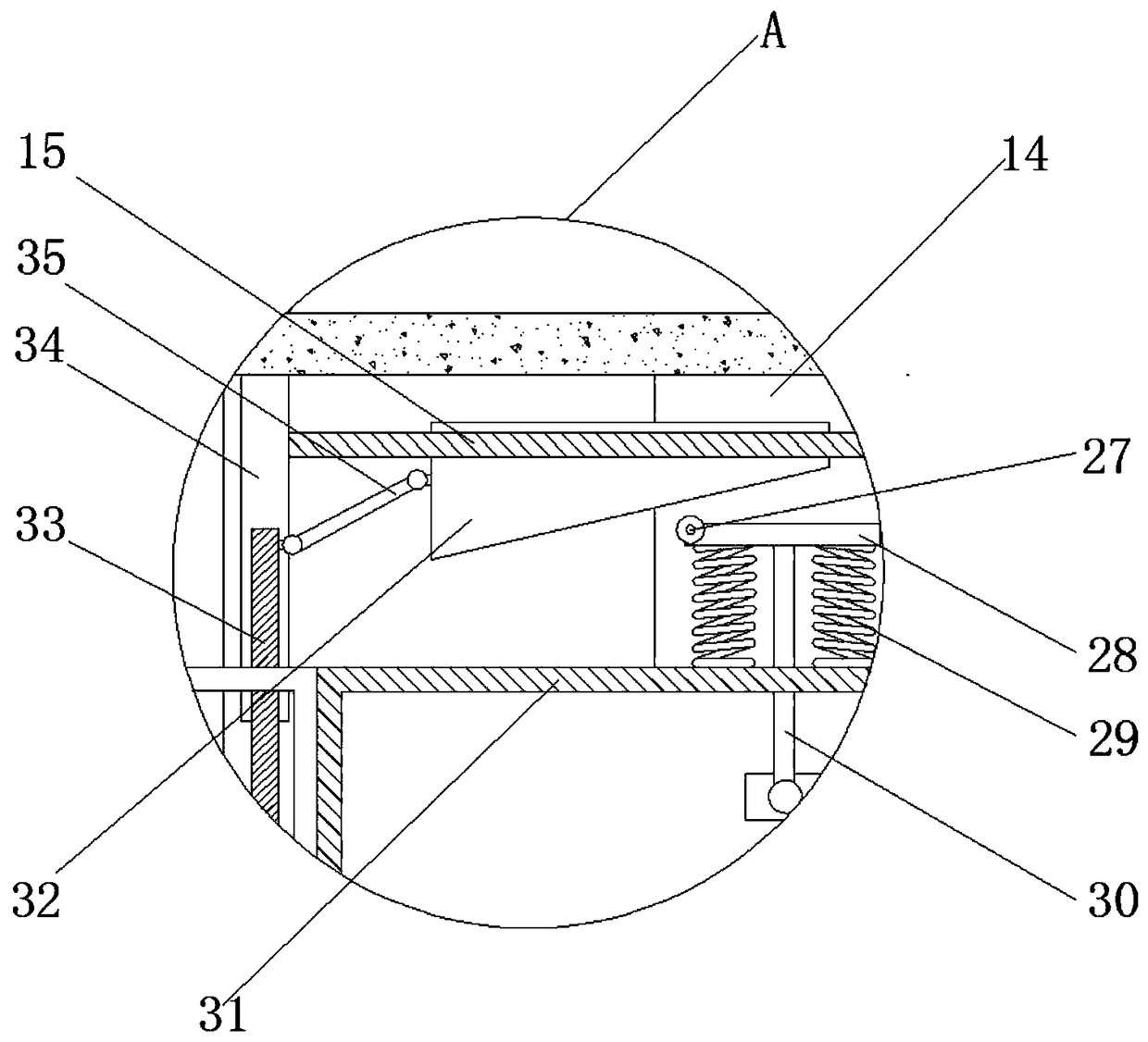

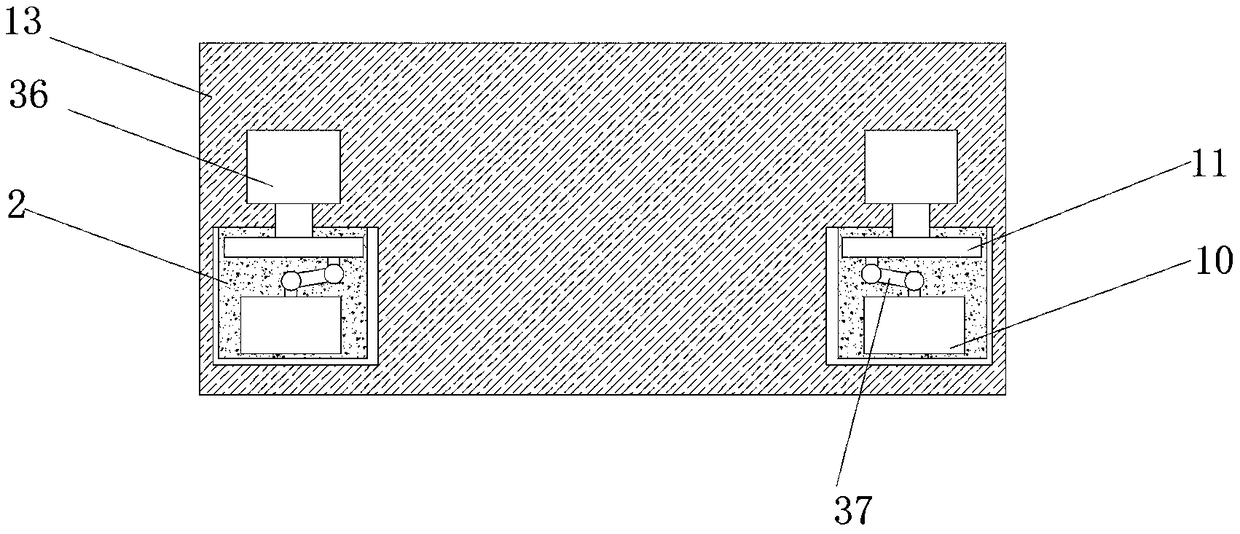

[0022] according to Figure 1-4 A fully automatic building ground compacting robot shown includes a fourth housing 31, a battery 16, a first motor 9, a second motor 12 and a third motor 36, and the bottom of the fourth housing 31 is welded with a first fixing rod 18 One side of the first fixed rod 18 is welded with a first fixed plate 19, and one side of the first fixed plate 19 is welded with a first mating rod, and one end of the first mating rod is provided with a wheel 24, and the number of the wheels 24 is 14. A second matching rod is welded on one side of the wheel, and one end of the second matching rod is provided with a first gear 21, and one side of the inner wall of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com