Accelerated-heat-aging test device used for inspection of automobile parts

A technology of auto parts and test equipment, which is applied in the direction of measuring equipment, instruments, scientific instruments, etc., can solve the problems of local temperature difference, low gas heating efficiency and unevenness of the equipment, so as to reduce the inaccuracy of test data and improve the heating efficiency. The effect of efficiency and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

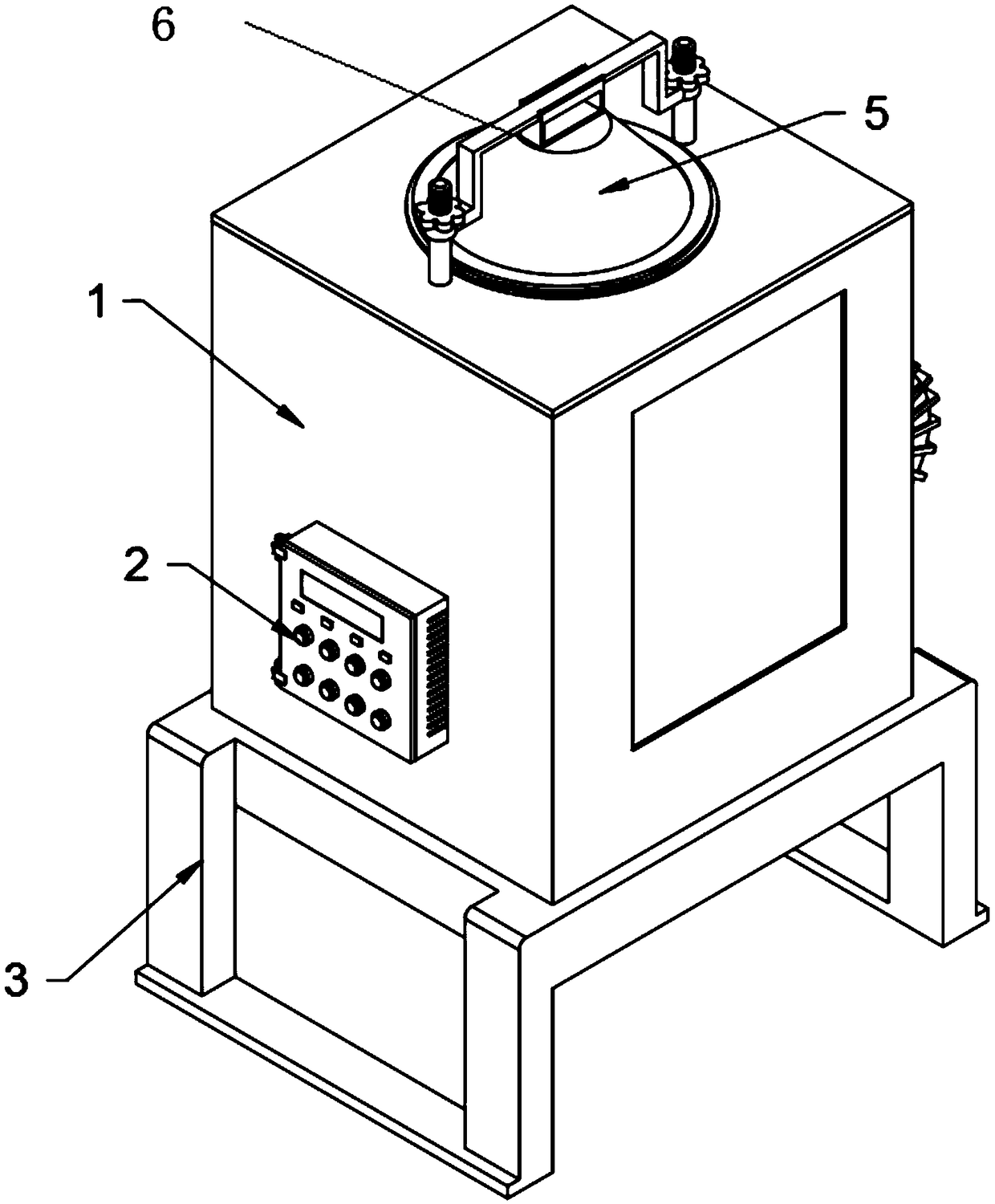

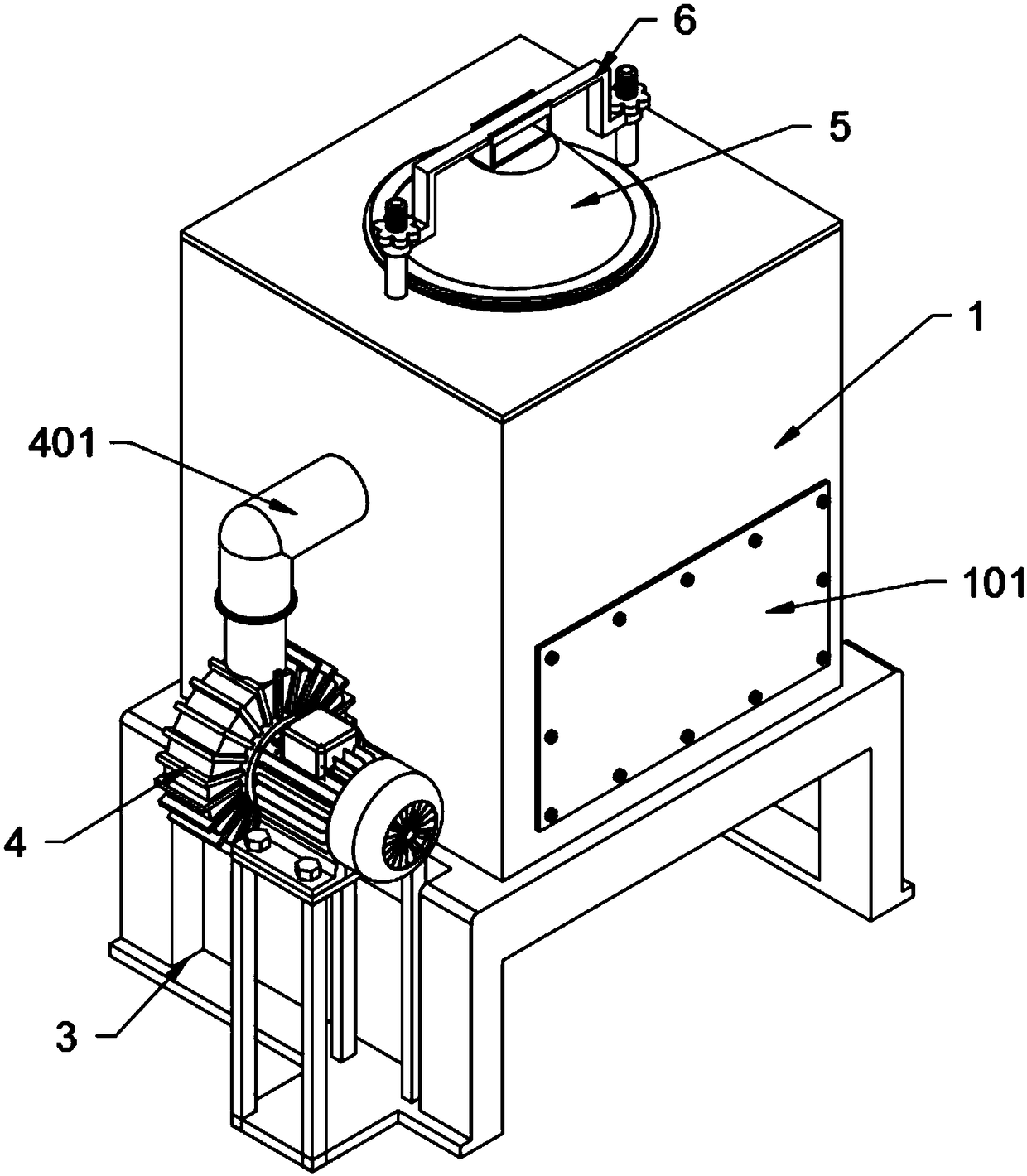

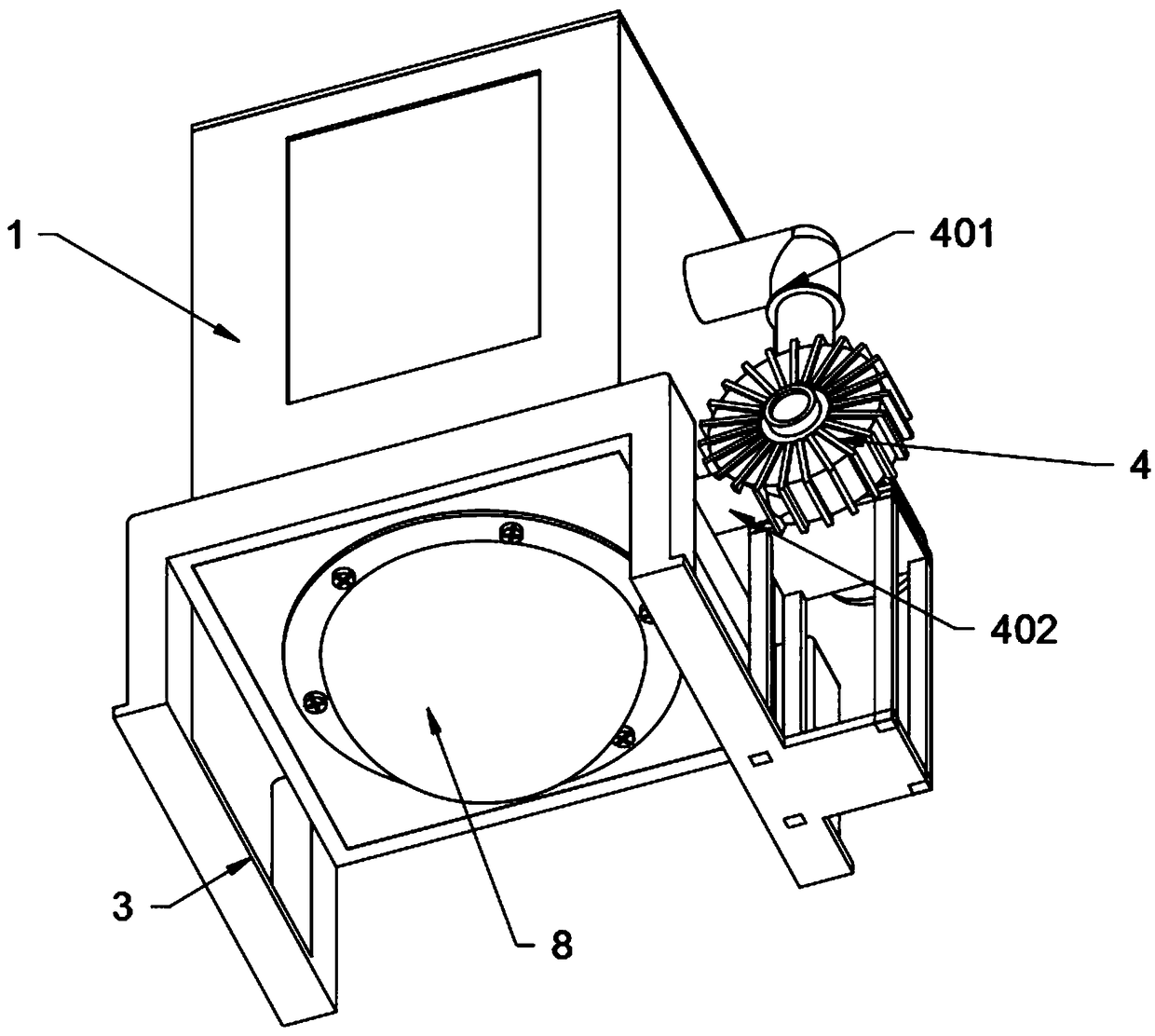

[0036] as attached figure 1 to attach Figure 10 :

[0037]The present invention provides an accelerated thermal aging test device for inspection of auto parts, including a box body 1, a blocking plate 101, a control electrical box 2, a support frame 3, a blower 4, an air outlet pipe 401, and an exhaust pipe 402 , cover 5, pressing plate 6, outer cloth air cylinder 7, installation cover 8, hemispherical protrusion 801, electric heating tube 9, cyclone cylinder 10, air outlet cover 11, Jiaolong air guide blade 1101, air guide plate 12 , threaded cover 13, support hanging rod 1301, positioning boom 14, sliding top cover 15, positioning insertion rod 1501, upper positioning ring 16 and lower positioning ring 17; There is a transparent glass plate installed in the front, and a support frame 3 is installed on the bottom support; a control electric box 2 is welded and installed on the left side wall of the box body 1, and there are two integrated installations inside the control e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com