Selective laser melting technological process energy consumption prediction and energy-saving control method

A laser melting and process technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of reducing energy consumption, high accuracy, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The present invention selects the SLM 280 of German SLM Solutions company HL Selective laser melting equipment, the equipment is equipped with two fiber lasers with a power of 400W, the two lasers can work independently or simultaneously, and the single-layer powder spreading time is 11s.

[0033] Taking the processing of waveguide parts as an example, the method of the present invention is used to predict the energy consumption of the SLM process, and then select the most energy-saving process scheme to realize green manufacturing. The processing parameters of this part are shown in Table 1.

[0034] Table 1

[0035]

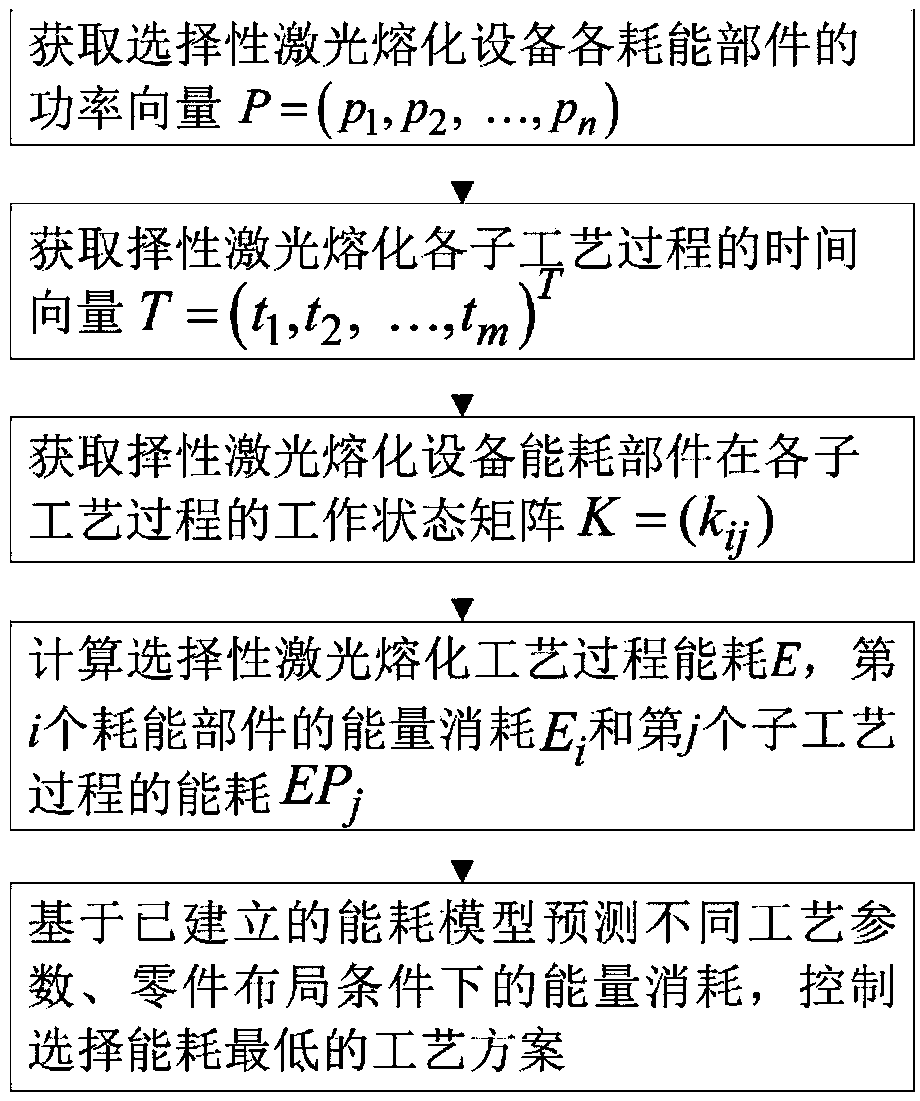

[0036] Such as figure 1 Shown, the step of the inventive method is as follows:

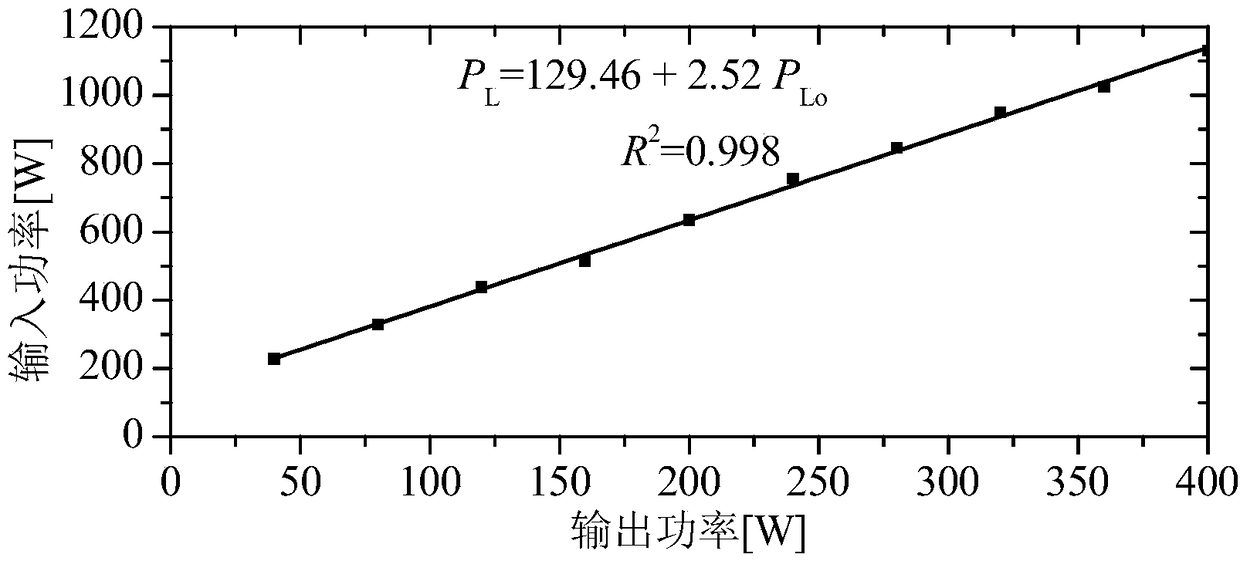

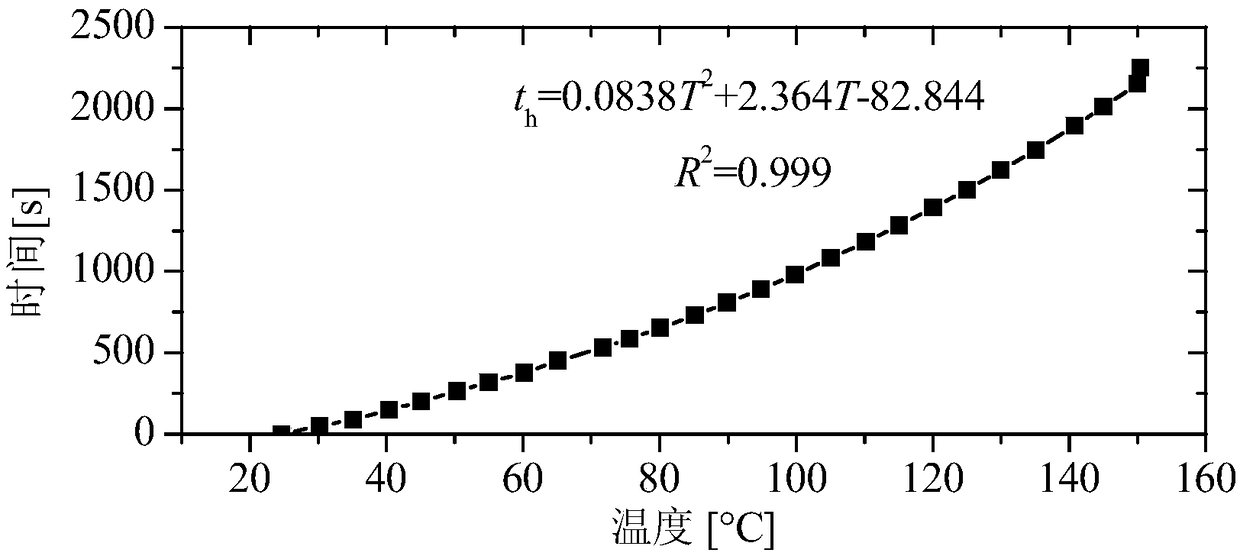

[0037] Step 1. Obtain the power of each energy-consuming component of the selective laser melting equipment. The method of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com