A kind of preparation method of iron-doped bismuth tungstate

A bismuth tungstate and iron doping technology, applied in the field of materials, can solve problems such as poor electrical conductivity, achieve the effects of reducing diffusion distance, reducing internal resistance, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

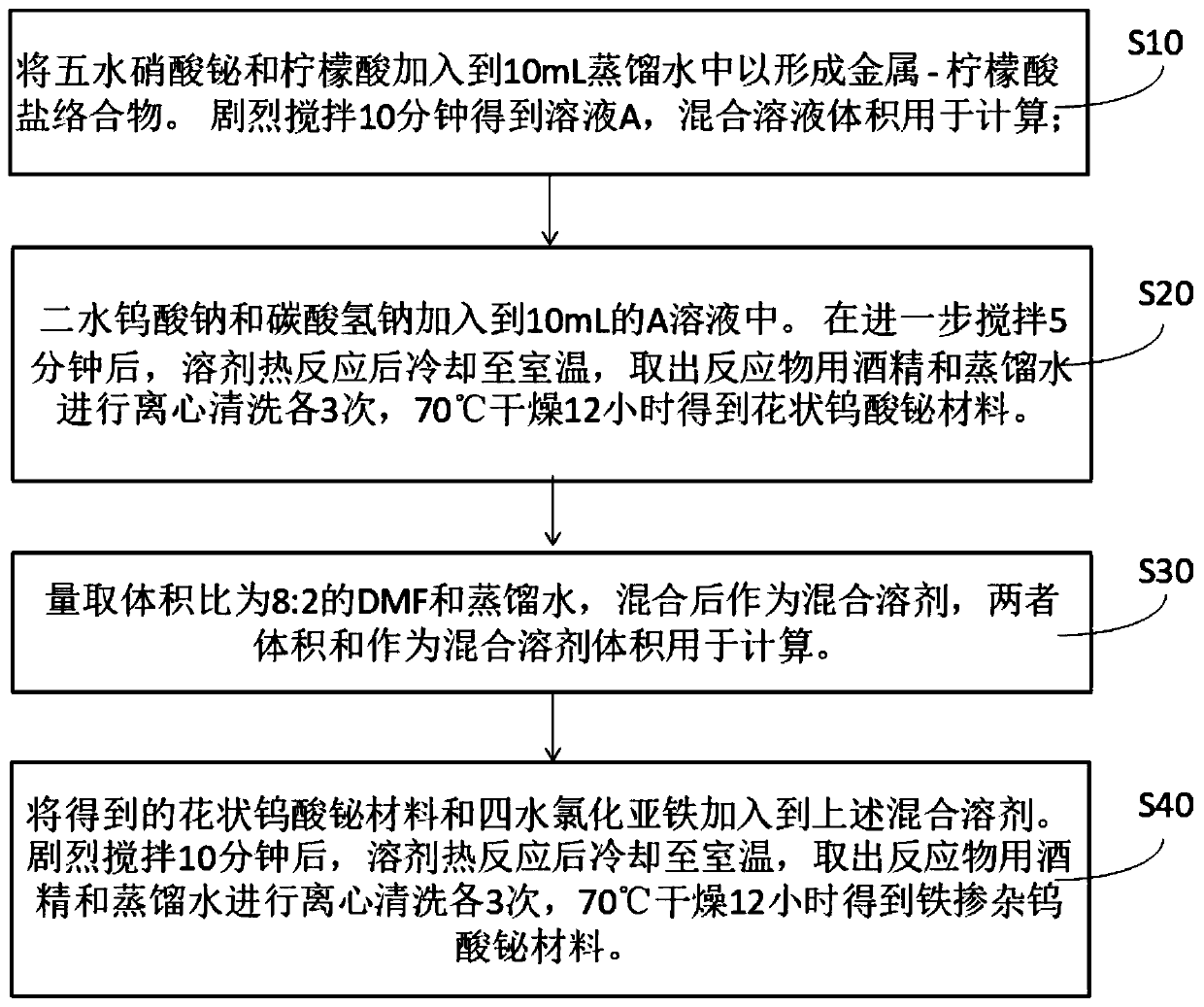

[0027] see figure 1 , shows a flow chart of the steps of a method for preparing an iron-doped bismuth tungstate material according to an embodiment of the present invention, which includes the following steps:

[0028] S10, weigh bismuth nitrate pentahydrate and citric acid with a molar ratio of 1:1 and dissolve them in 10 mL of distilled water to form a metal-citrate complex. After vigorously stirring for 10 minutes, a mixed solution was obtained, and the volume of the mixed solution was used for calculation;

[0029] S20, weigh sodium tungstate dihydrate and sodium bicarbonate with a molar ratio of 1:4 and dissolve in 10mL of A solution. After further stirring for 5 minutes, the solvothermal reaction was followed by cooling to room temperature; the reactant was taken out and washed by centrifugation with alcohol and distilled water three times each, and dried at 70°C for 12 hours to obtain a flower-shaped bismuth tungstate material.

[0030] Bi in the above reaction +3 Fo...

Embodiment 1

[0037] S10, add 0.25mmol Bi(NO 3 ) 3 ·5H 2 O was added to 10 mL of aqueous solution containing 0.25 mmol of citric acid to form a metal-citrate complex. After vigorous stirring for 10 minutes, solution A was obtained.

[0038] S20, add 0.125mmol Na 2 WO 4 2H 2 O and 0.5 mmol NaHCO 3 added to the above solution. After further stirring for 5 minutes, the solution was poured into a Teflon-lined stainless steel autoclave with a capacity of 20 mL, and kept at 180°C for 15 hours and then cooled to room temperature; the reactant was taken out and washed by centrifugation with alcohol and distilled water three times each , and dried at 70°C for 12 hours to obtain a flower-like bismuth tungstate material.

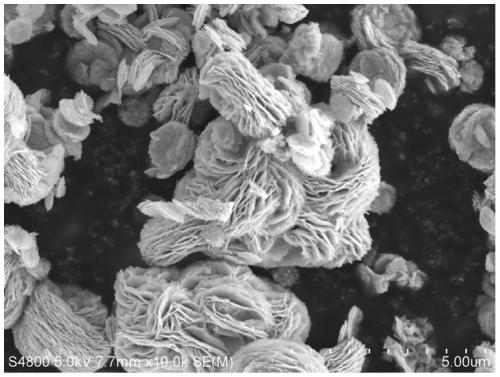

[0039] pass figure 2 Observe that the 2um-5um flower-shaped bismuth tungstate prepared in the above steps is relatively smooth and well stacked into a flower-like structure, so that the surface area is relatively large, which is convenient for the next step.

[0040] S30,...

Embodiment 2

[0044] S10, add 0.25mmol Bi(NO 3 ) 3 ·5H 2 O was added to 10 mL of aqueous solution containing 0.25 mmol of citric acid to form a metal-citrate complex. After vigorous stirring for 10 minutes, solution A was obtained.

[0045] S20, add 0.125mmol Na 2 WO 4 2H 2 O and 0.5 mmol NaHCO 3 added to the above solution. After further stirring for 5 minutes, the solution was poured into a Teflon-lined stainless steel autoclave with a capacity of 20 mL, and kept at 180°C for 12 hours and then cooled to room temperature; the reactant was taken out and washed by centrifugation with alcohol and distilled water three times each , and dried at 70°C for 12 hours to obtain a flower-like bismuth tungstate material.

[0046] S30, measure the DMF and distilled water that volume ratio is 8:2, mix as mixed solvent, both volumes and as mixed solvent volume are used for calculation;

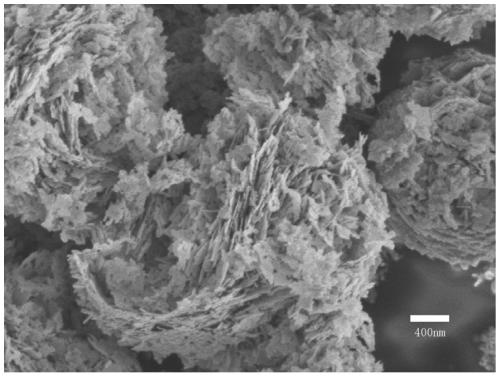

[0047] S40, the obtained 0.125mmol flower-like bismuth tungstate material and 0.07mmol

[0048] FeCl 2 4H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com