Liquid immersion cooling type automobile power battery pack

A power battery pack and liquid immersion technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems that fans cannot meet the heat dissipation requirements of power batteries, high cost, and complex non-contact liquid cold plate cooling structure. Simple, fast heat dissipation, and the effect of improving heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

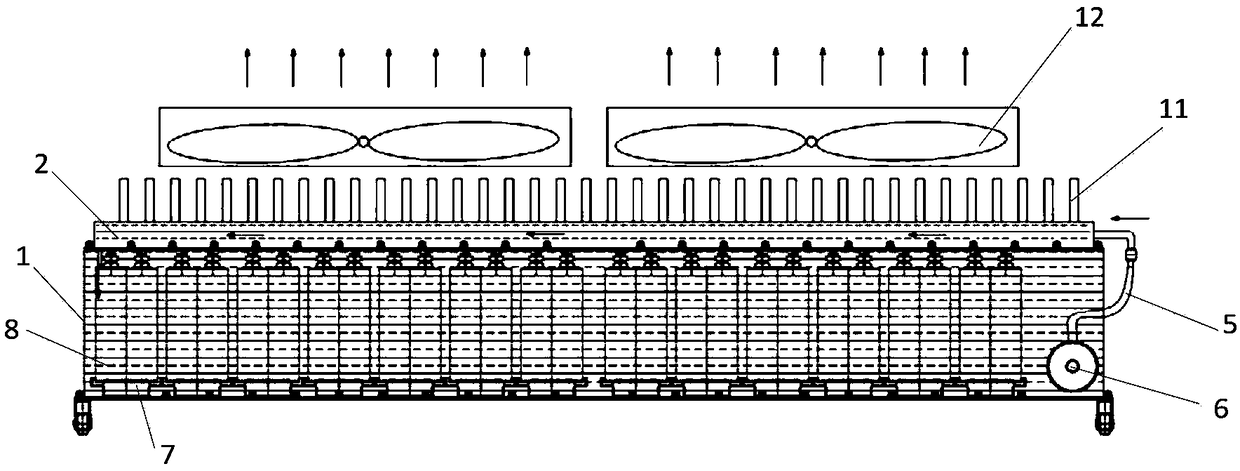

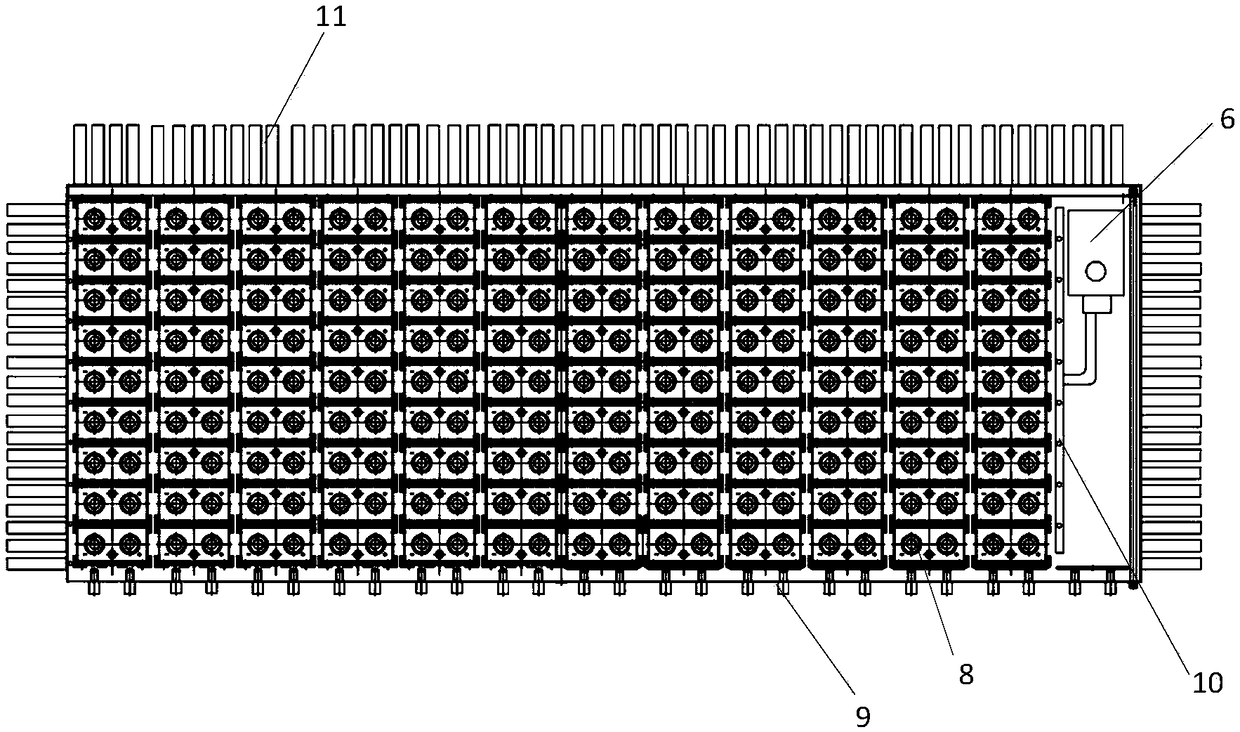

[0022] like Figure 1-2 As shown, a liquid immersion cooling type automotive power battery pack provided in this embodiment includes a casing 1 with an open upper end, a cover body 2 sealingly connected with the upper opening of the casing 1, and a cover for connecting with the outside The connecting terminal for circuit connection, the cover body 2 is provided with a hollow chamber, the housing 1 is provided with a battery pack, insulating cooling liquid and a pump 6, the connecting terminal is electrically connected with the battery pack, and the The insulating cooling liquid fills the inner space of the housing 1, the pump 6 is connected to the hollow chamber of the cover 2 through the pipeline 5, and the lower surface of the cover 2 is provided with a The interior of the hollow chamber with the liquid outlet. Specifically, the connecting terminal 9 is used as the power output terminal to supply power to the automobile. A large amount of heat will be generated during the c...

Embodiment 2

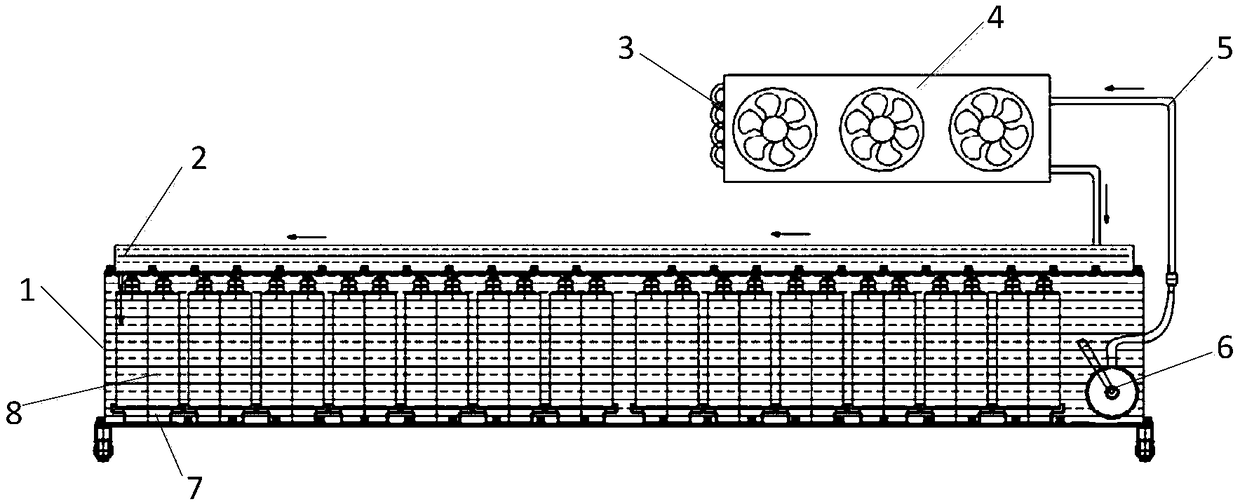

[0030] like image 3 As shown in the figure, a liquid immersion cooling type automotive power battery pack provided in this embodiment, the difference between this embodiment and Embodiment 1 is that the heat dissipation fins 11 and the heat dissipation fan 12 on the cover body 2 are cancelled. The spray-cooled vehicle power battery pack also includes an air-cooled radiator 4 , the pipeline 5 includes a heat-dissipating section 3 , and the heat-dissipating section 3 is a coiled tubular structure, and the heat-dissipating section 3 and the air-cooled radiator 4 Connected to and located in the air-cooled radiator 4, specifically, when the pump 6 sucks the insulating cooling liquid in the housing 1 and flows to the heat-dissipating section 3, the air-cooled radiator 4 flows through the heat-dissipating section 3. The insulating cooling liquid is cooled by air to ensure that the temperature of the insulating cooling liquid flowing out from the cooling section 3 and entering the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com