3D printer based on cylindrical coordinate system

A technology of 3D printer and cylindrical coordinate system, which is applied in the field of 3D printing, can solve the problems such as the decrease of the overall stability of the mechanism, the influence of printing accuracy, and the fatigue damage of parts, so as to achieve the effect of reducing inertial load, large printing range and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

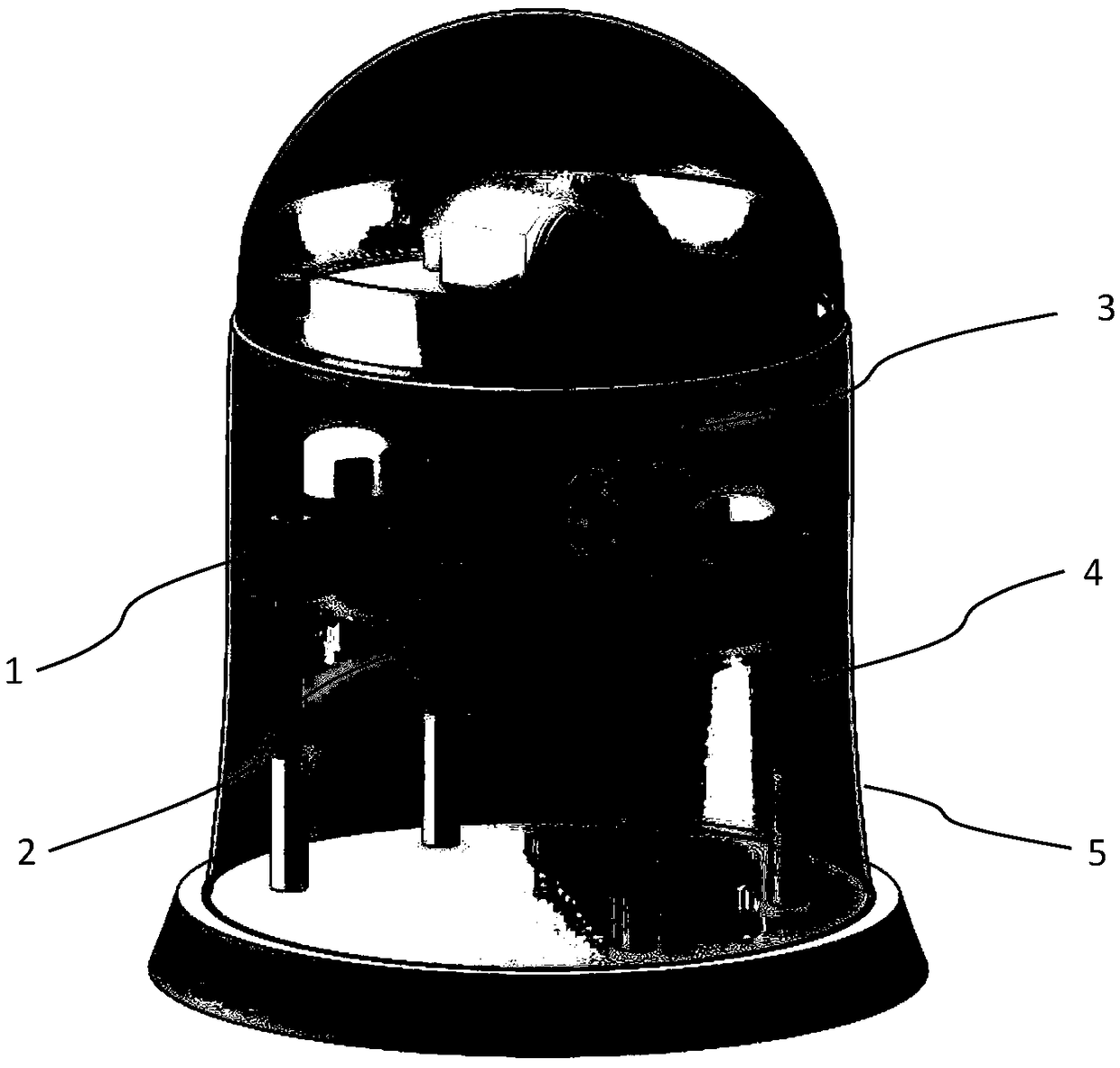

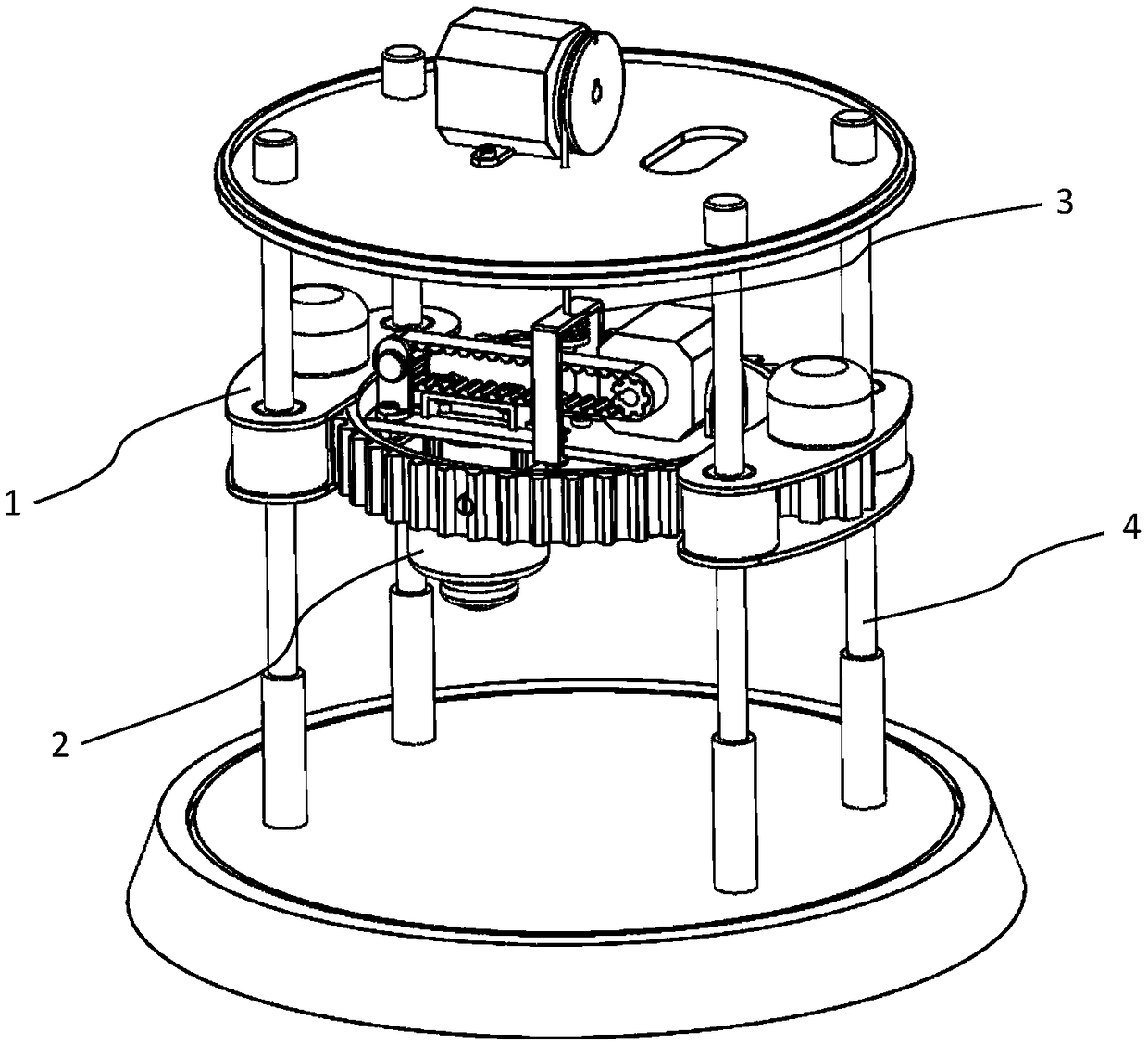

[0034] Such as figure 1 As shown, the main structure of the present invention includes an annular module 1, a nozzle module 2, a lifting module 3, a main body frame 4 and a printer cover 5, wherein the annular module 1 can complete the circumferential rotational drive and the radial linear motion of the printer nozzle module 2. Drive, the lifting module 3 can complete the lifting drive of the printer nozzle module 2, the nozzle module 2 can evenly eject printing consumables to achieve additive molding, and the main frame 4 serves as the printer frame to support other components and make the overall structure stable. , the printer cover 5 can protect the workpiece from being polluted by external sundries during the additive molding process, and also avoid safety accidents.

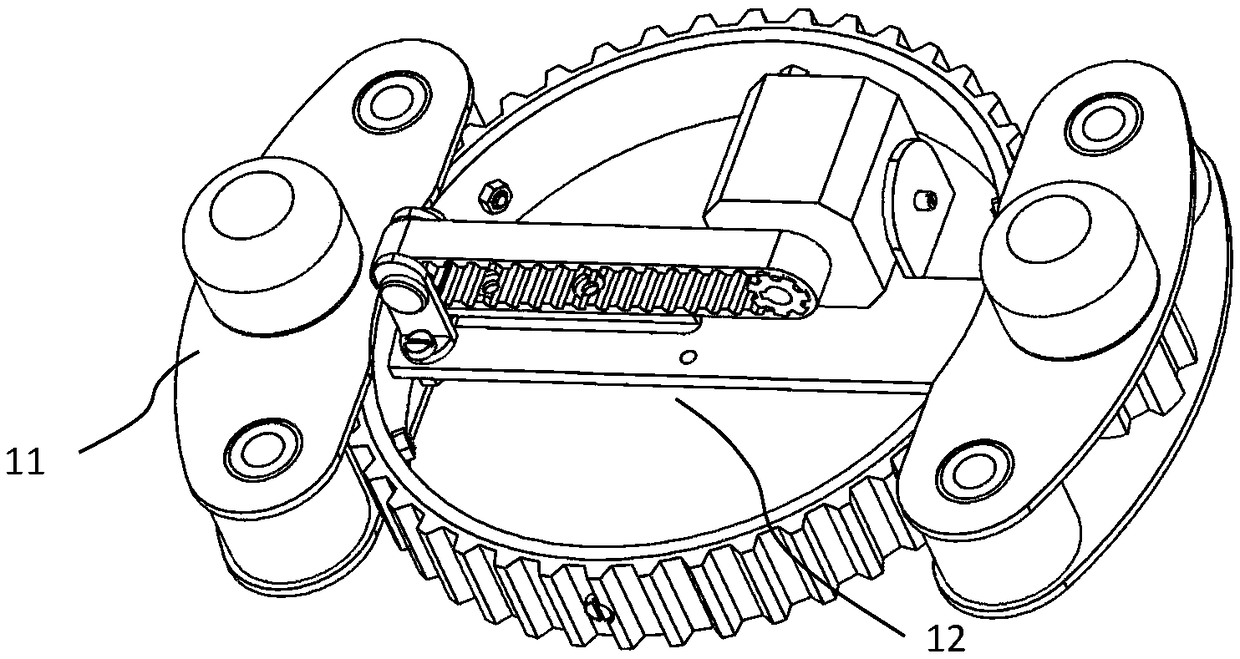

[0035] Specifically, the structure and principle of a 3D printer based on a cylindrical coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com