Elevator diversion sheave assembly

A technology of anti-rope pulleys and components, which is applied to elevators, hoisting devices, transportation and packaging in buildings, etc., which can solve the problems of safety accidents, traction wire rope detachment, and cumbersome replacement of anti-rope pulleys, and reduce replacement time , to avoid safety accidents, easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

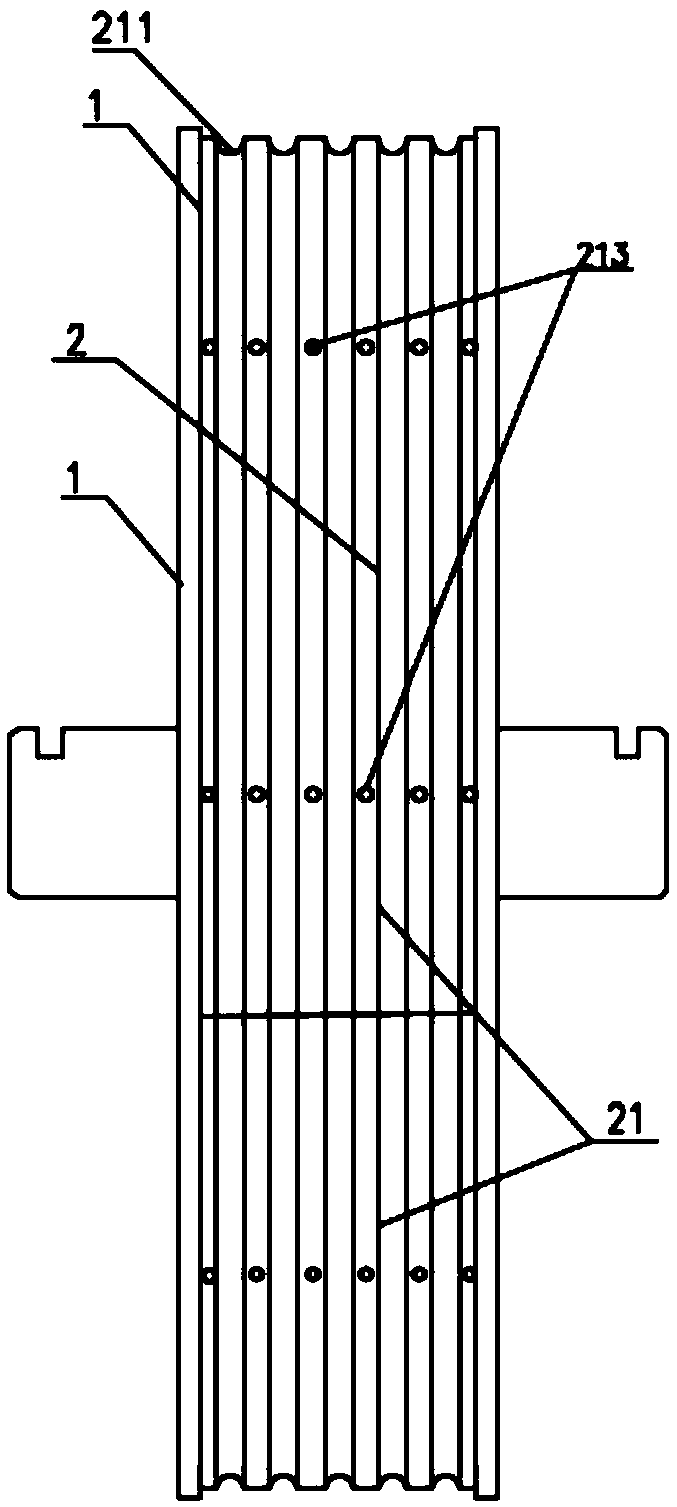

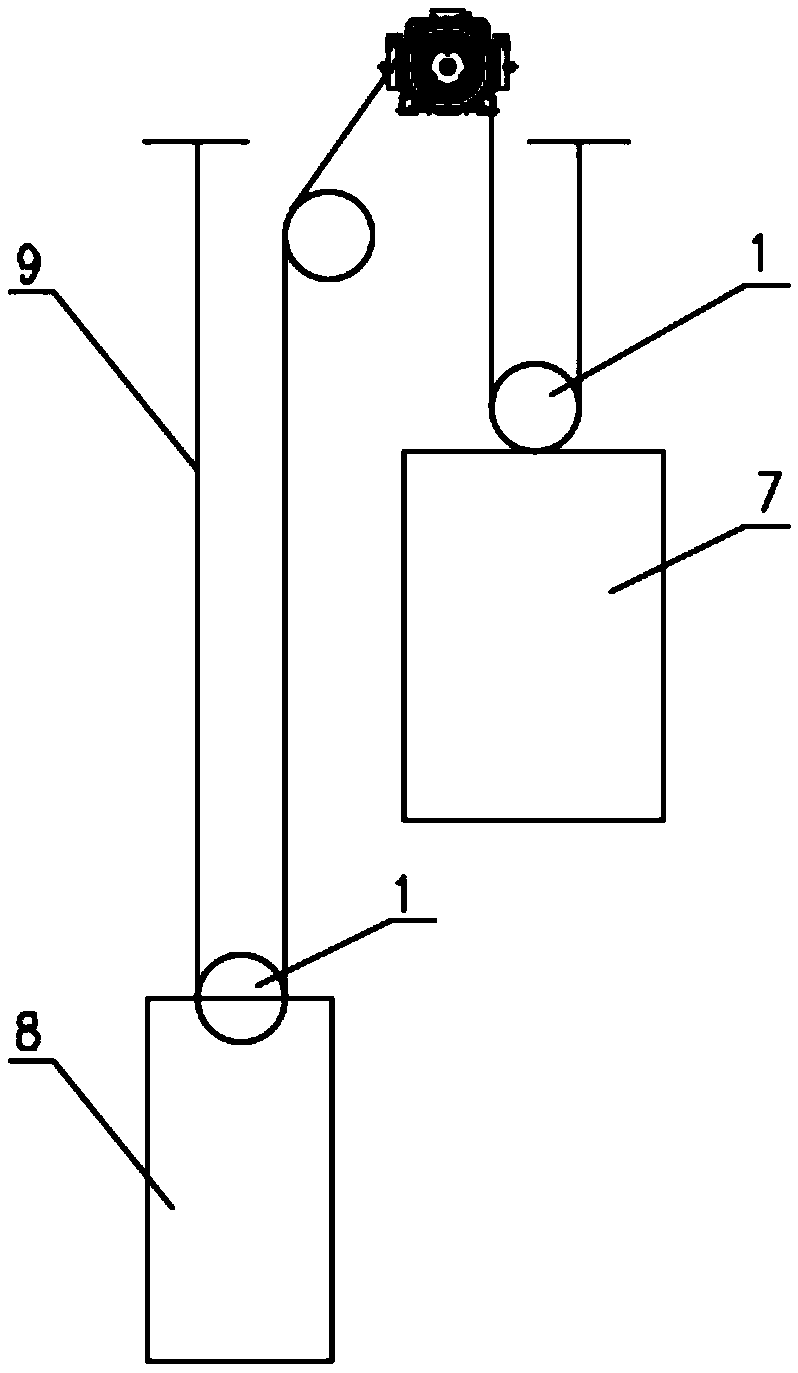

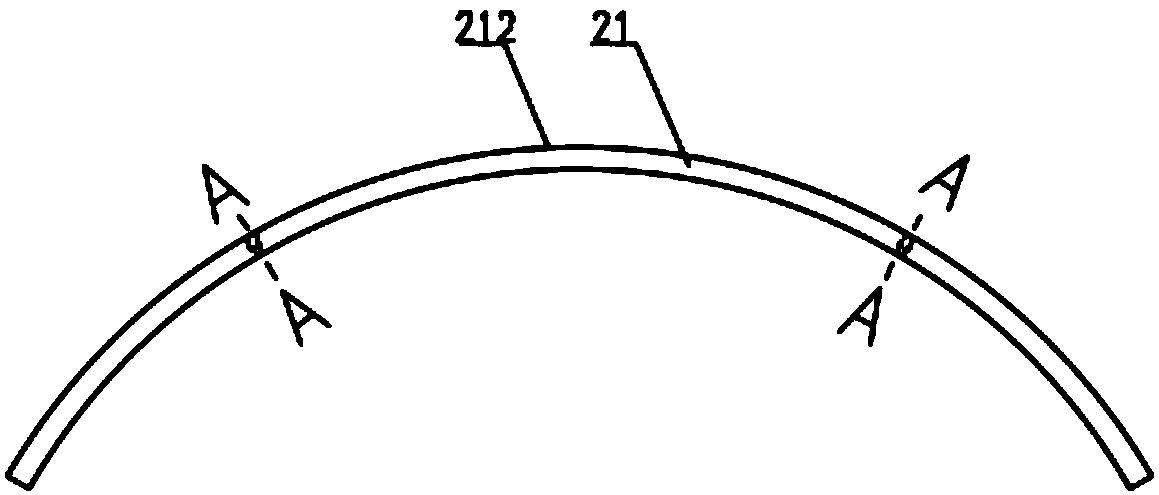

[0020] Such as Figure 1 to Figure 6 As shown, an elevator anti-sheave assembly includes a sheave body 1 and a rope groove body 2, the sheave body 1 is provided with an annular groove 11 matching the rope groove body 2, and the rope groove body 2 is composed of two or More than two rope groove belts 21 are formed, and one or more rope grooves 211 matching the traction wire rope 9 are arranged on the rope groove belt 21 .

[0021] The principle of use of this scheme is: when the elevator is running up and down, the traction wire rope 9 is located in the rope groove 211, and the anti-rope pulley assembly and the traction wire rope 9 are driven by sliding friction. Therefore, after the elevator has been running for a long time, when the anti-rope When the wheel assembly rope groove 211 was severely worn, only the rope groove belt 21 needed to be replaced, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com