Method and system for deiciing of air foil wings of composite material

A composite material, rotor technology, used in deicing devices, transportation and packaging, final product manufacturing, etc., can solve problems such as being unsuitable for large windmills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

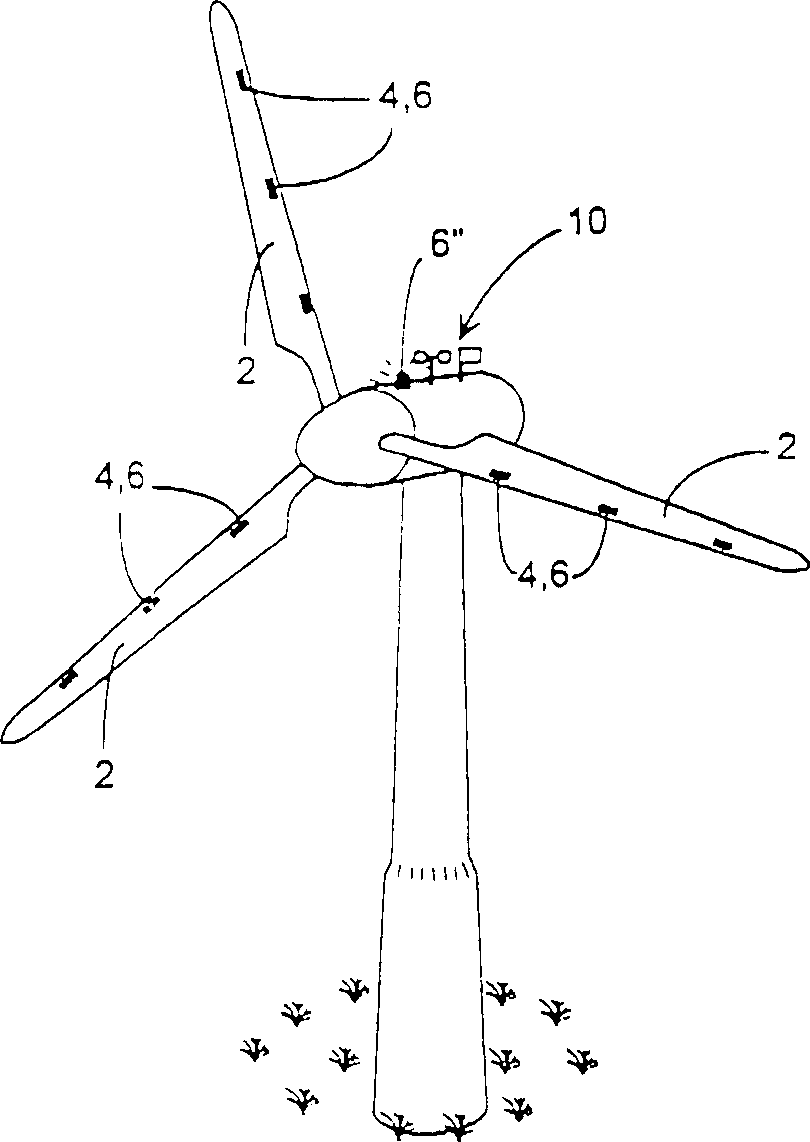

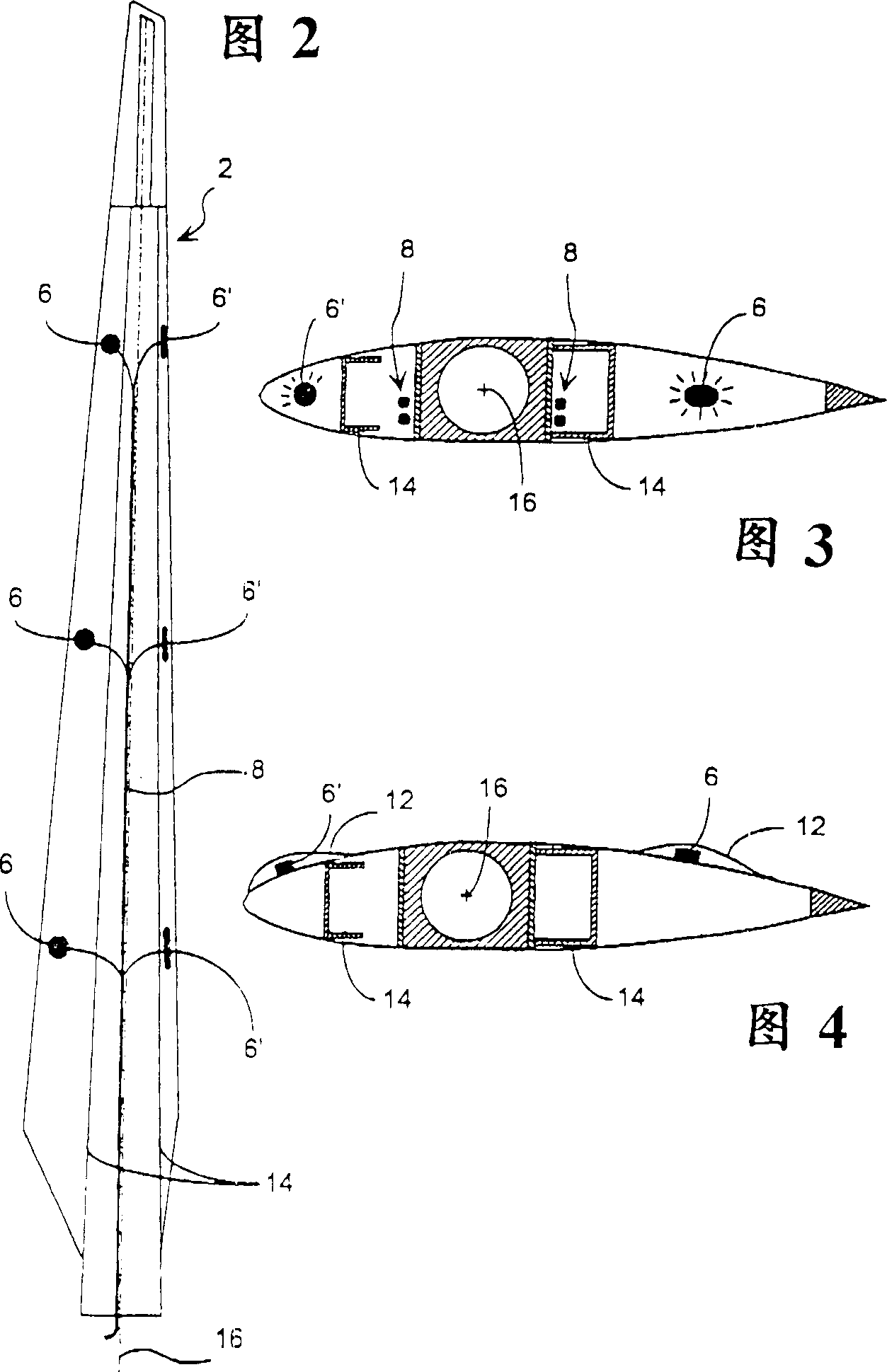

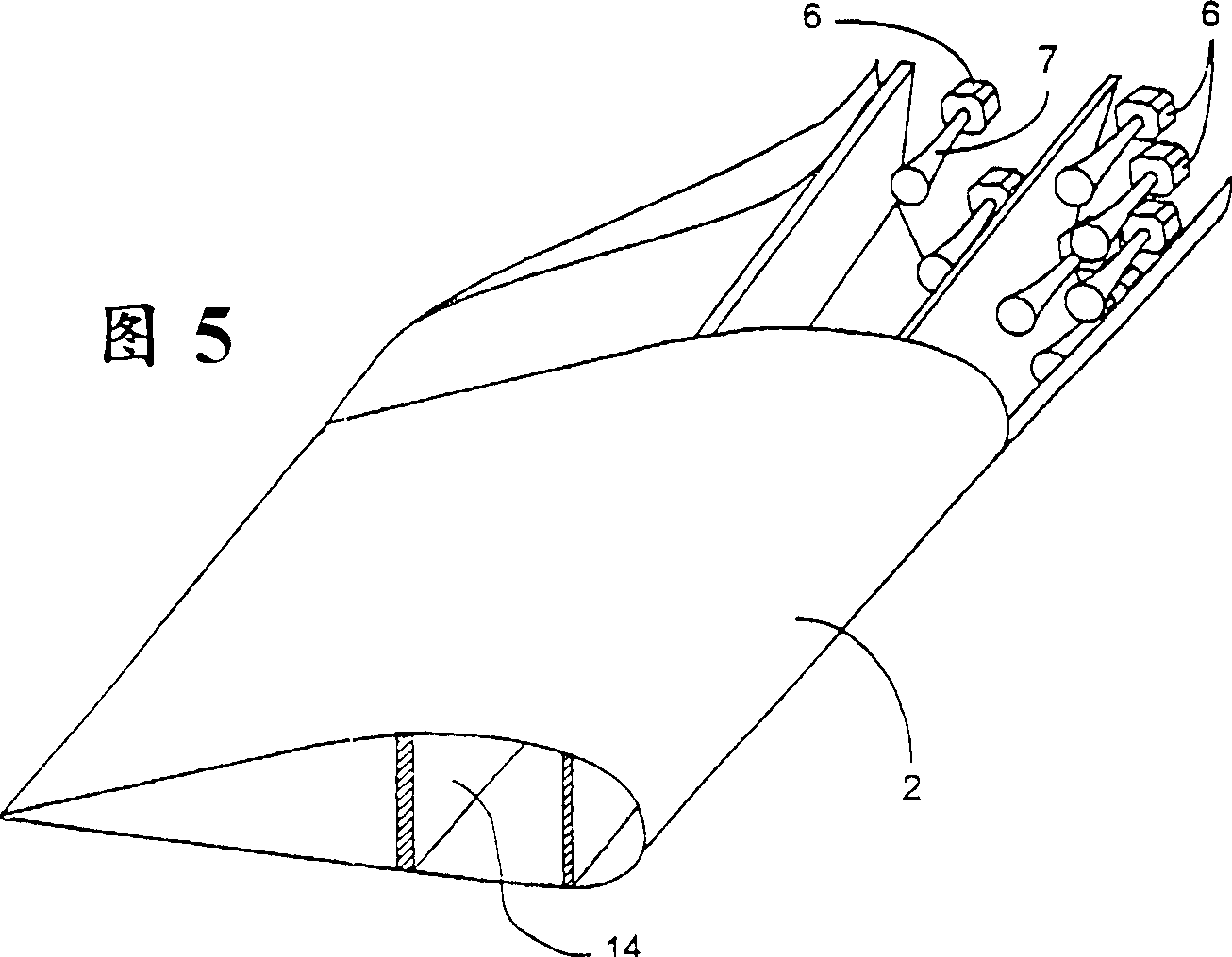

[0021] figure 1 A windmill is shown with a microwave heating system installed in it. The microwave equipment includes a plurality of microwave generators 6 installed on or in the rotor 2. In a preferred embodiment, a plurality of generators can be arranged in the rotor (as shown in FIGS. 2 and 3). Microwave generators 6' are preferably located along the leading edge of the rotor 2 in order to heat the leading edge area intensively. Certainly, the microwave generator 6 can also be arranged at other places on the rotor 2, as shown in Fig. 2, 3, 4.

[0022] When multiple microwave generators are mounted on the rotor, the rotor can be heated in sections. Optionally, the system can also be arranged so that each segment includes one or more generators 6, combined by a control system with humidity and temperature probes (not shown) also located on the rotor, so that only those segments that are icy are heated . A differential, demand-controlled heating of the rotor surface sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com