Strength checking method based on connecting structure of nozzle and pressure shell

A pressure-bearing shell and connection structure technology, applied in the field of pressure-bearing equipment, can solve problems such as connecting pipes and openings without external loads, and achieve the effect of improving design work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

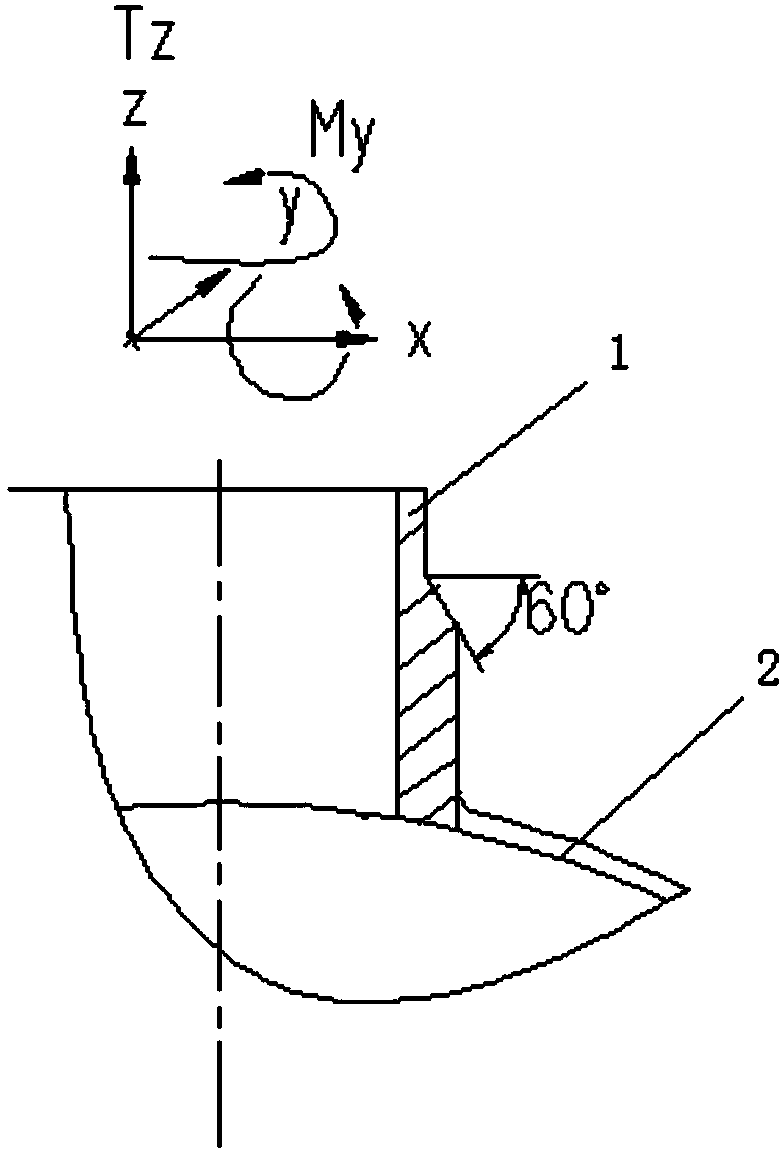

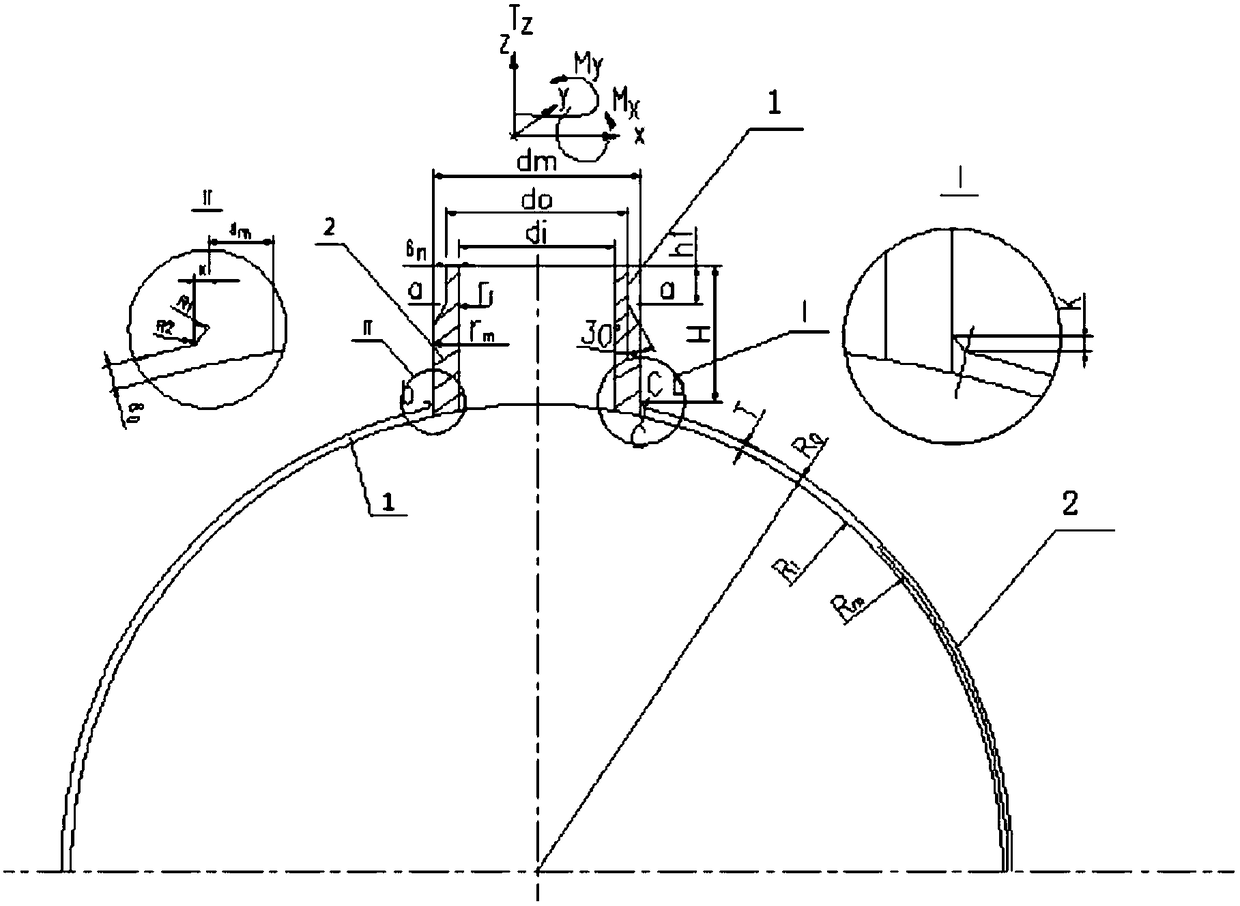

[0445] Specific implementation mode 2. In combination with the drawings of the specification, based on the strength checking method of the connection structure between the connecting pipe and the pressure-bearing shell, combined with actual engineering examples, the strength and reinforcement calculation of the connection between the connecting pipe and the spherical shell are checked;

[0446] 1. Conditions

[0447] Calculated pressure Pc 6MPa, design temperature t 275°C, spherical shell material Q345R, connecting pipe material 20# forging, spherical shell inner diameter Di 3150, spherical shell inner radius Ri 1575, spherical shell outer radius Ro 1627, spherical shell wall thickness δ O53, the inner diameter of the connecting pipe is di 500, the outer diameter of the small end of the connecting pipe is do 586, the outer diameter of the large end of the connecting pipe is dm 670, and the wall thickness of the small end of the connecting pipe is δ n 43, the wall thickness of...

specific Embodiment approach 3

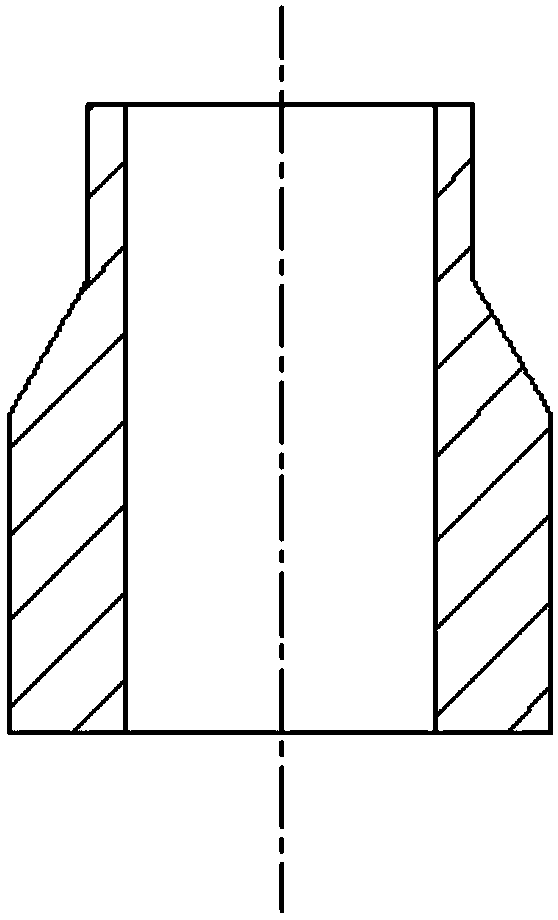

[1004] Specific implementation method 3. Calculation and verification of strength reinforcement connecting the connecting pipe and the cylindrical shell:

[1005] 1. The wall thickness of the connecting pipe itself should meet the requirements of internal pressure, and the thickness of the connecting pipe itself under pressure should be calculated according to GB150.3;

[1006] Applicable range of pipe wall thickness: P C t φ

[1007] The formula for calculating the wall thickness of the pipe:

[1008] 2. The wall thickness of the cylindrical shell is checked, and the thickness required for bearing pressure is calculated according to GB150.3;

[1009] The scope of application of the wall thickness of the cylindrical shell:

[1010] P C ≤0.4[σ] t φ

[1011]

[1012] 3. Check the strength of the aa section of the connecting pipe;

[1013] The strength check of the takeover aa section is consistent with the specific implementation mode two, the strength check mode of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com