Barrel middle beehive

A beehive and barrel-type technology, applied in the field of barrel-type beehives, can solve the problems of difficulty in making, using and large-scale production, leaving space for bee colonies, difficult operation and transportation, etc., so as to reduce the interference of bee colonies and larvae, Easy to take honey, good temperature and humidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

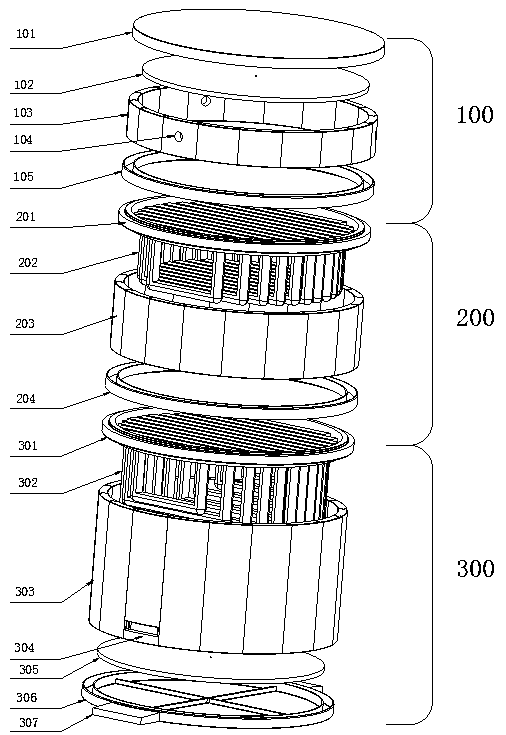

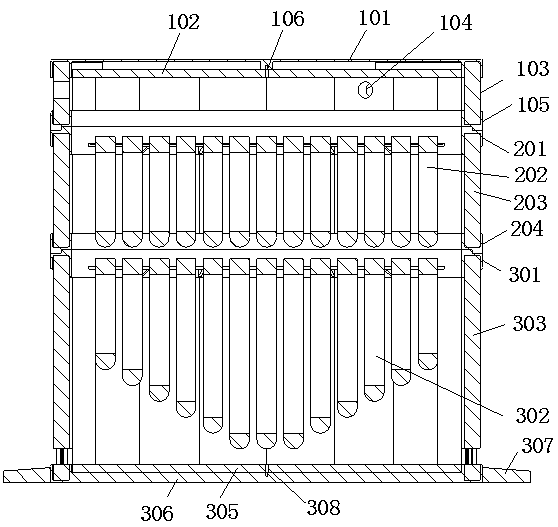

[0040] See Figure 1 to Figure 11 , The present invention provides a technical solution: a barrel type medium beehive, comprising a barrel lid 100, a barrel relay box 200, and a bottom barrel box 300 that are screwed together from top to bottom, and a barrel is arranged inside the barrel relay box. Following the box nest frame 202, a bottom bucket box nest frame 302 is arranged inside the bottom bucket box, and the bucket lid includes a bucket lid side enclosure body 103 and a bucket lid top plate connected to a port on the side enclosure body of the bucket lid, The side enclosure body of the barrel lid is formed by inserting at least four pieces of barrel lid side enclosure body inserting plates end to end in sequence; the barrel relay box includes a barrel relay box body 203, the barrel relay box body It is formed by inserting at least four barrels followed by the box plug-in board from the end to the end in turn; the bottom barrel box includes a bottom barrel box body 303 an...

Embodiment 2

[0051] Such as Figure 13 , Figure 14 , Figure 15 Shown: The present invention provides a technical solution: a barrel type medium beehive, comprising a barrel cover, a barrel relay box, and a bottom barrel box that are screwed together from top to bottom, and a barrel relay is arranged inside the barrel relay box. A box nest frame, wherein a bottom bucket box nest frame is arranged inside the bottom bucket box, and the bucket box cover includes a bucket lid side enclosure and a bucket lid top plate connected to a port on the side enclosure body of the bucket lid. The lid side enclosure is formed by at least four pieces of barrel lid side enclosure insert plates that are inserted in turn from end to end; the barrel relay box includes a barrel relay box body, and the barrel relay box body consists of at least four barrels After the box body inserting plate is inserted and enclosed in turn; the bottom bucket box includes a bottom bucket box body and a bottom bucket box bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com