Three-dimensional modeling method

A technology of three-dimensional modeling and programming, applied in the direction of additive manufacturing, improvement of process efficiency, energy efficiency, etc., can solve problems such as lack of disclosure and enlightenment, and achieve the effect of avoiding defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

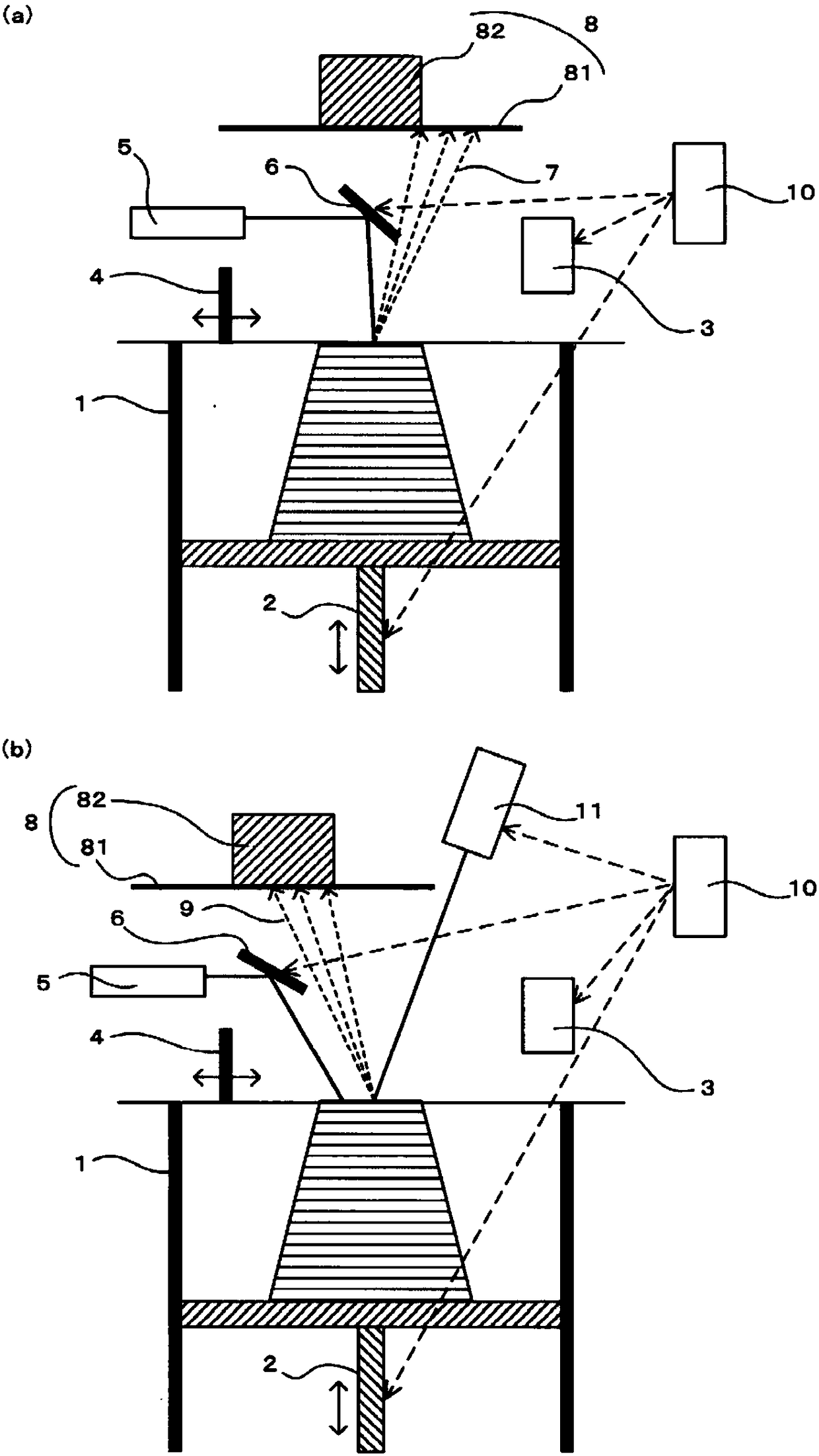

[0114] Embodiment 1 is characterized in that the cause of poor sintering is corrected, and for the entire sintered area including the sintered position indicated by procedure c, or the entire sintered area and the entire sintered area already stacked on the lower side of the area, by After the laser beam or electron beam is melted or softened, only the thickness amount of the melted or softened region or the thickness amount of the sintered and laminated sintered region is removed, or after all the above-mentioned sintered regions are removed by a cutting tool, the The layering step and the sintering step are repeated for the removed area.

[0115] To explain the technical gist of Example 1, even if the position and its vicinity causing poor sintering indicated by procedure c are melted and removed by laser beam or electron beam, in the case of lamination and sintering again for this area, it is necessary to Image analysis is performed on the melted and removed regions, and la...

Embodiment 2

[0120] The second embodiment is characterized in that sintering abnormality is notified by a light signal and / or an audio signal when the program c is instructed.

[0121] With such a feature, poor sintering can be quickly dealt with.

[0122] In particular, when a different color light signal or a different sound is selected due to any one of A and B according to poor sintering, the cause of poor sintering can be quickly grasped and dealt with.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com