High temperature resistant adhesive and its preparation method and composite insulating paper

A composite insulation and adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of large energy consumption and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

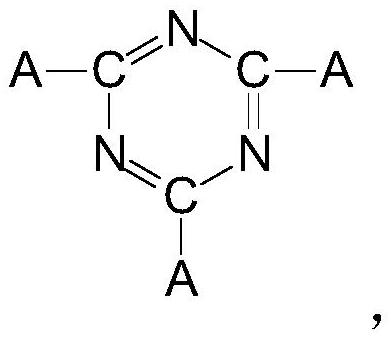

Problems solved by technology

Method used

Image

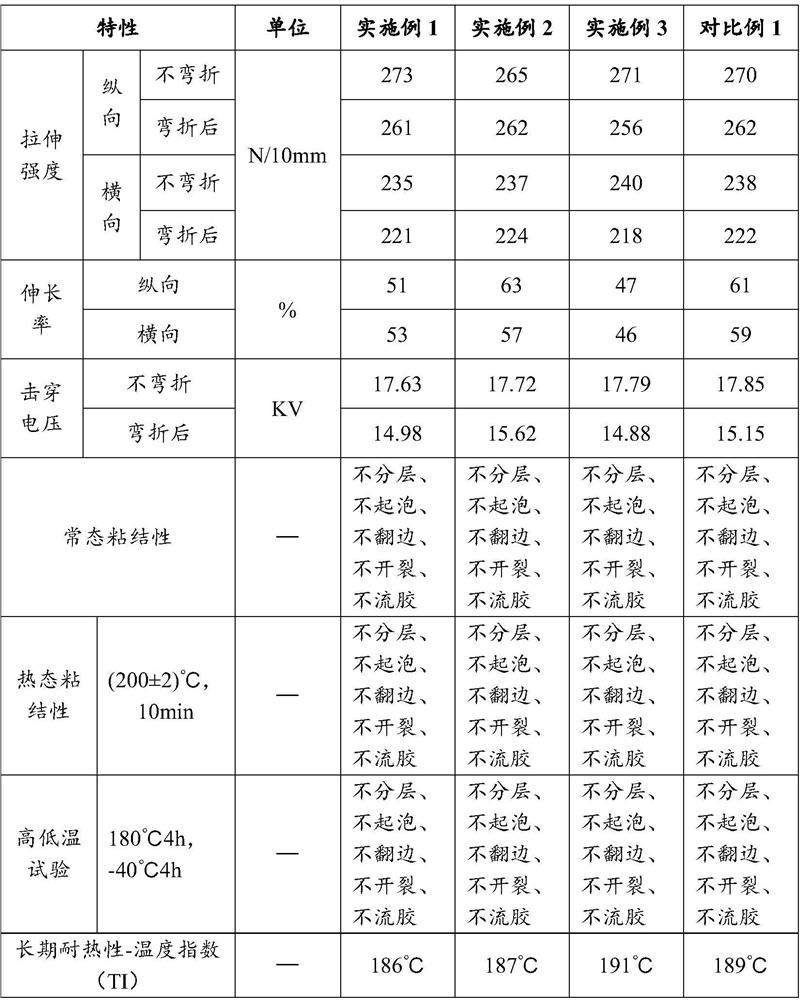

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing a high-temperature-resistant adhesive, which includes: adding each component of the above-mentioned high-temperature-resistant adhesive into a mixer, and stirring evenly.

[0022] In the method for preparing the high temperature resistant adhesive of the present invention, preferably, the stirring temperature is 70-110°C.

[0023] The present invention also provides a composite insulating paper, the composite insulating paper sequentially includes: a first fiber paper, a polyimide film, a second fiber paper; between the first fiber paper and the polyimide film, the The above-mentioned second fiber paper and the polyimide film are bonded by the high temperature resistant adhesive provided by the present invention.

[0024] In the composite insulating paper of the present invention, preferably, the first fiber paper is one or more of polyaramid fiber paper, polysulfone amide fiber paper, and inorganic fiber paper;...

Embodiment 1

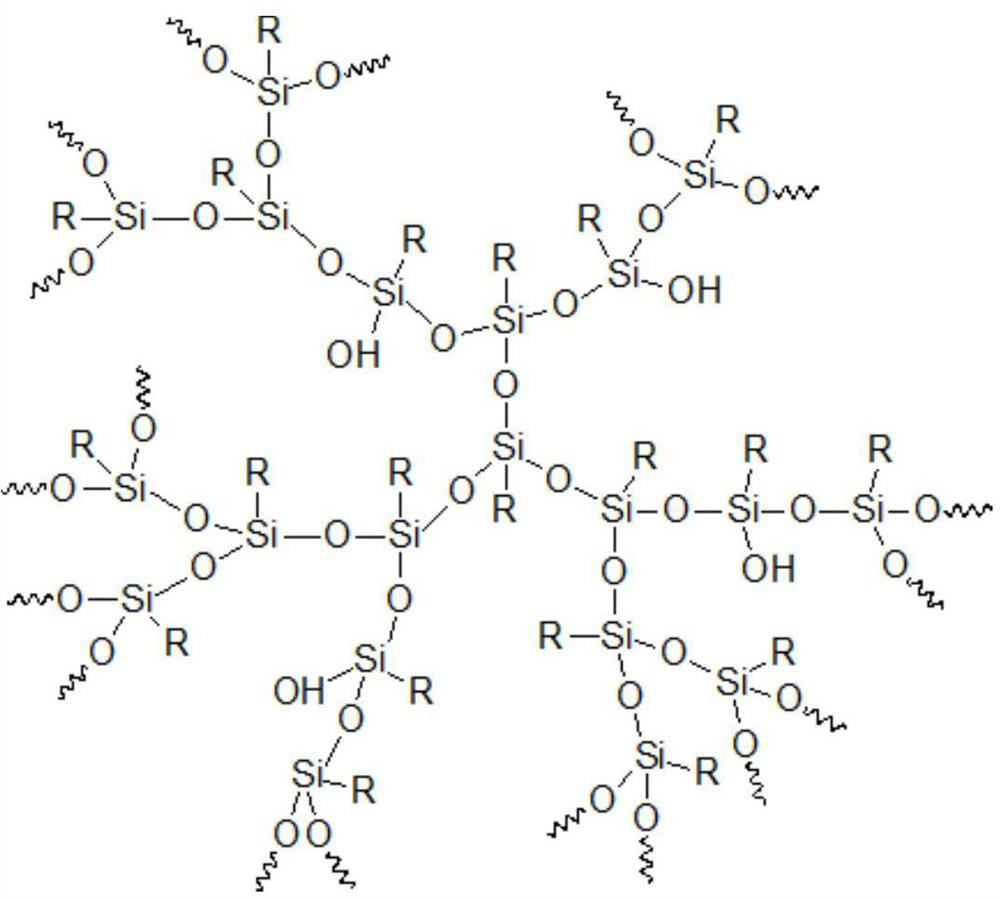

[0031] Based on the total weight of the high-temperature resistant adhesive, 70% by weight of cyanate resin and 3% by weight of polysiloxane-modified cyanate resin were stirred at 90°C; Hydroxyl hyperbranched polysiloxane, 6% by weight of nonylphenol, stirred and mixed evenly at 90° C. to obtain adhesive P1;

[0032] The above adhesive was cooled to 70°C and then coated on both sides of the polyimide film, and then combined with polyaramid fiber paper (Nomex 464 from DuPont Company) and cured at 110°C for 10 hours to obtain composite insulating paper PS1.

Embodiment 2

[0034] Based on the total weight of the high temperature resistant adhesive, 60% by weight of cyanate resin and 5% by weight of polysiloxane modified cyanate resin were stirred at 70°C; Epoxy hyperbranched polysiloxane, 8% by weight of nonylphenol, stirred and mixed evenly at 70°C to obtain adhesive P2;

[0035] The above adhesive was cooled to 50°C and coated on both sides of the polyimide film, and then combined with inorganic fiber paper (TufQUIN110 from 3M Company) and cured at 120°C for 10 hours to obtain composite insulating paper PS2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com