Vacuum freeze dryer

A vacuum freeze-drying and drying technology, which is applied in the direction of refrigerators, drying solid materials, and drying solid materials without heating, can solve the problems of long time-consuming, etc., and achieve the effects of simplified operation, high reliability and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

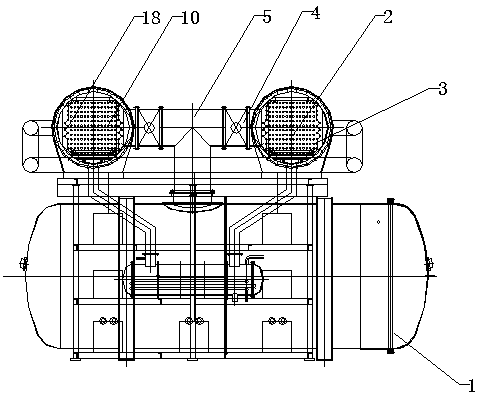

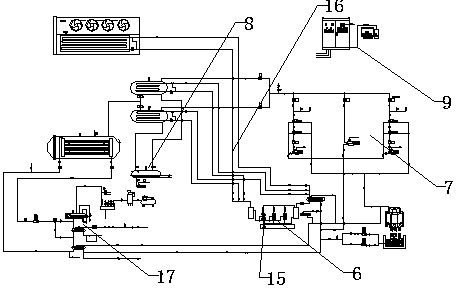

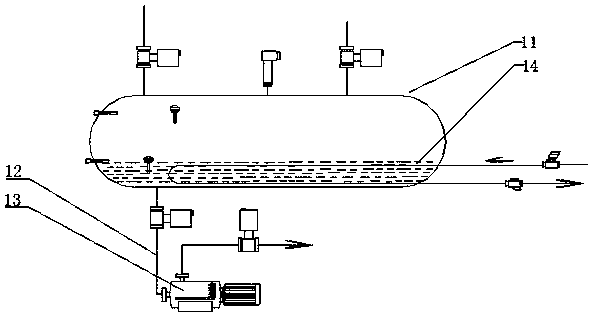

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a kind of vacuum freeze-drying machine provided by the present invention comprises: dry freeze box body 1 and two cold trap cabins 2, be positioned at the outside of dry freeze box body, be provided with cold trap pipe 3 in the described cold trap cabin, a One side of the cold trap cabin is equipped with a vacuum electric valve 4, and a pair of vacuum electric valves on the cold trap cabin are connected with two interfaces of the three-way pipe 5; the third interface of the three-way pipe is connected to the dry Freezing box; refrigeration system 6, connected to the cold trap pipe; the refrigeration system is used to freeze the materials in the dry freezer; vacuum system 7, used to maintain the vacuum degree in the dry freezer; ice melting system 8, used to melt The frost that freezes in the cold trap cabin; the control system 9, the control system is electrically connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com