Modular rocker arm

A modular, rocker arm assembly technology used in engine components, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Reference will now be made in detail to the examples illustrated in the drawings. Where possible, the same reference numerals will be used throughout the drawings to refer to the same or similar parts. Directional references such as "left" and "right" are for easy reference to figures.

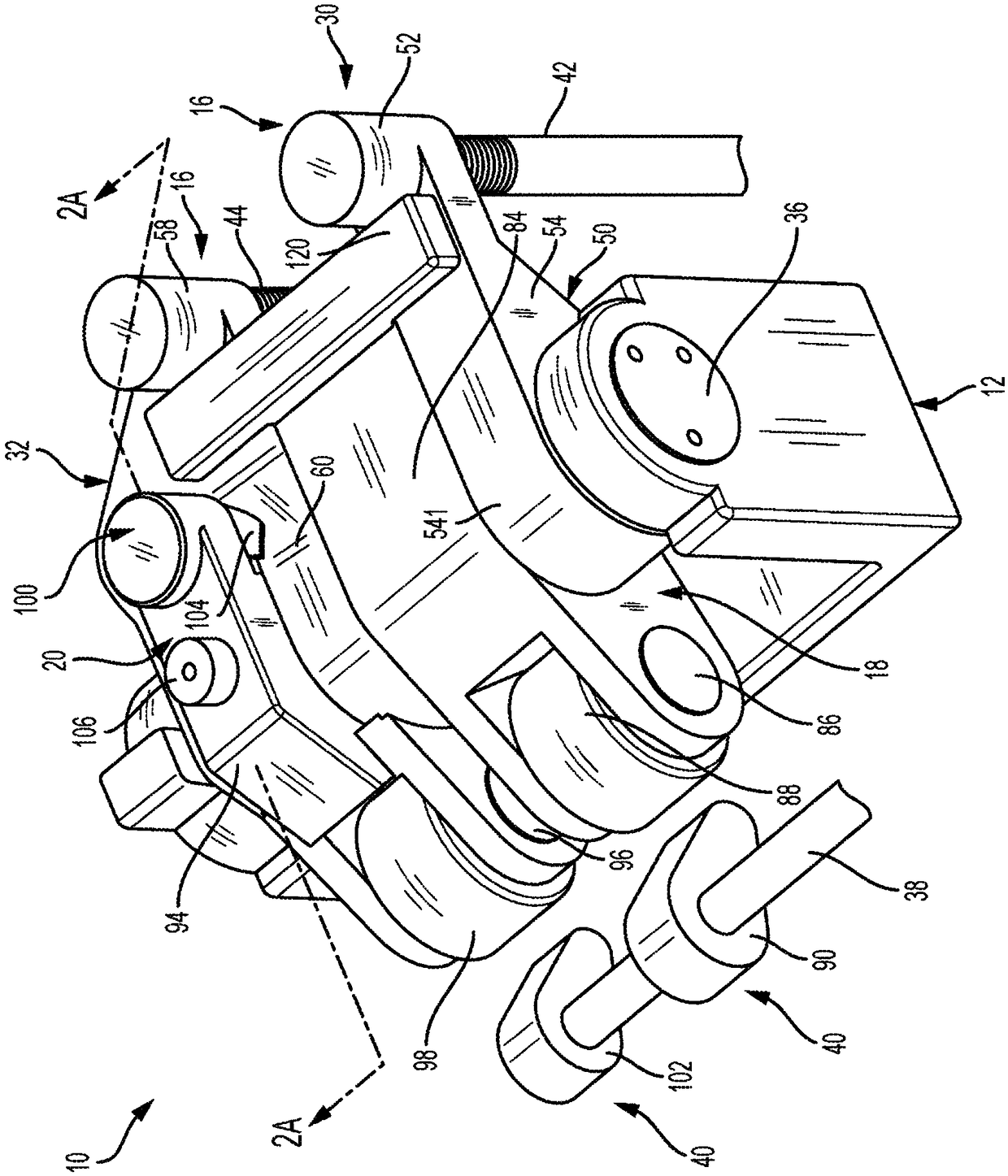

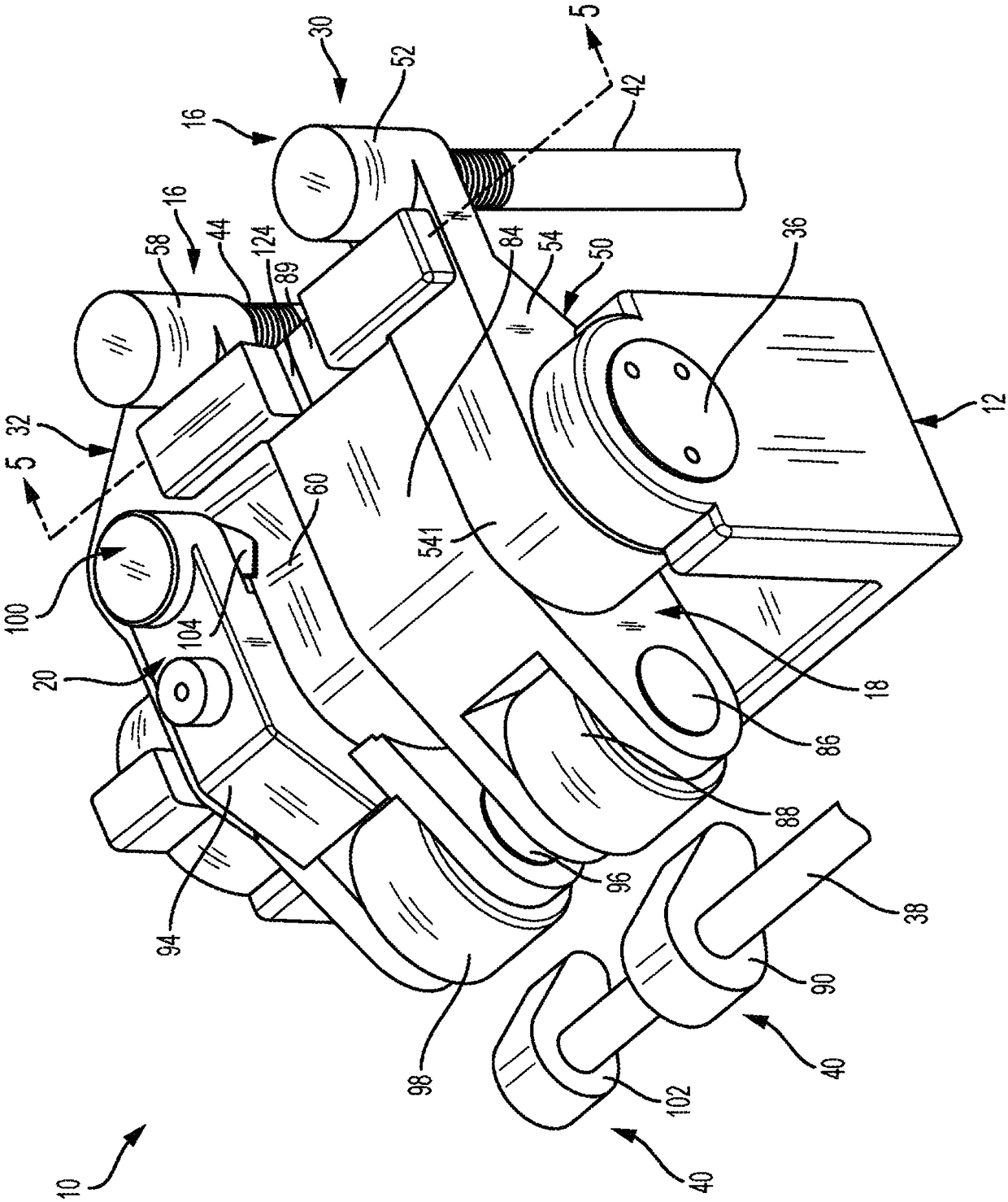

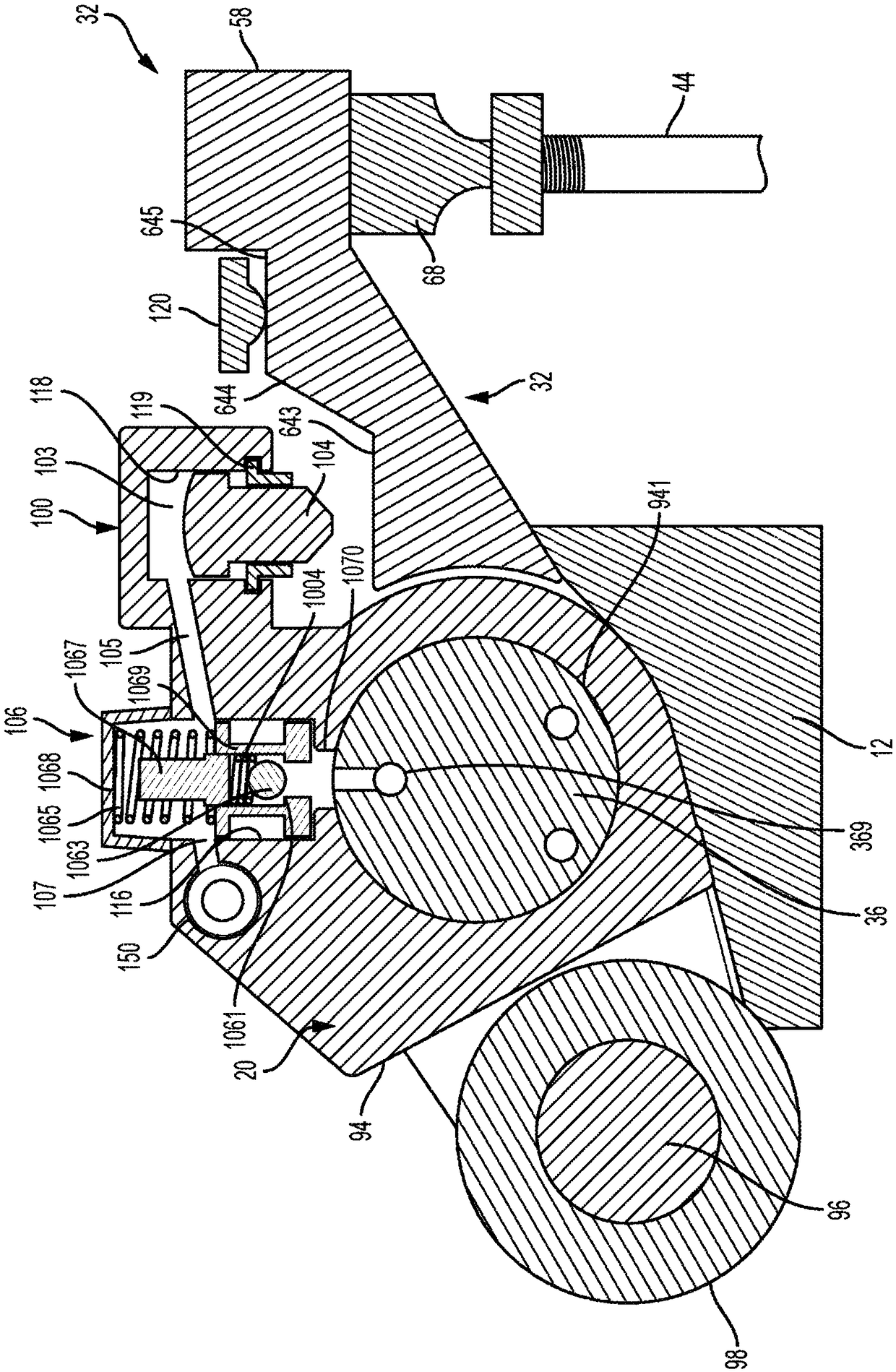

[0016] First reference Figure 1A with 1B According to examples of the present disclosure, partial modular valve mechanism components 10, 11 are constructed. As described herein, the partial modular valve mechanism components 10, 11 utilize various combinations of modular features to provide various combinations of the following variable valve actuation (VVA) functions: cylinder deactivation (CDA), two-stroke, or four-stroke Stroke decompression engine braking (EB), hydraulic clearance adjustment (HLA) and intake or exhaust variable valve lift (VVL), the intake or exhaust variable valve lift includes the delayed closing of the intake valve ( LIVC) and the exhaust valve open early (EEVO). ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap