Method and apparatus for manufacturing optical sheet module

A technology of optical sheets and equipment, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as difficulty in using and pressing the upper and lower optical sheets, and reduce the quality of optical sheet modules, so as to minimize the penetration depth, Effects of preventing deterioration of adhesive quality and minimizing deterioration of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

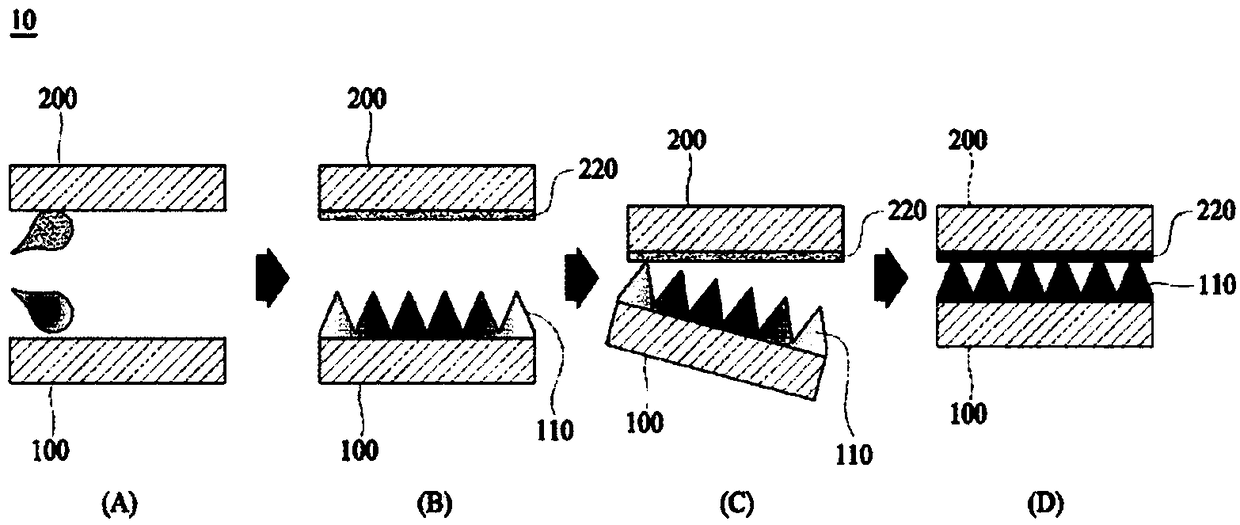

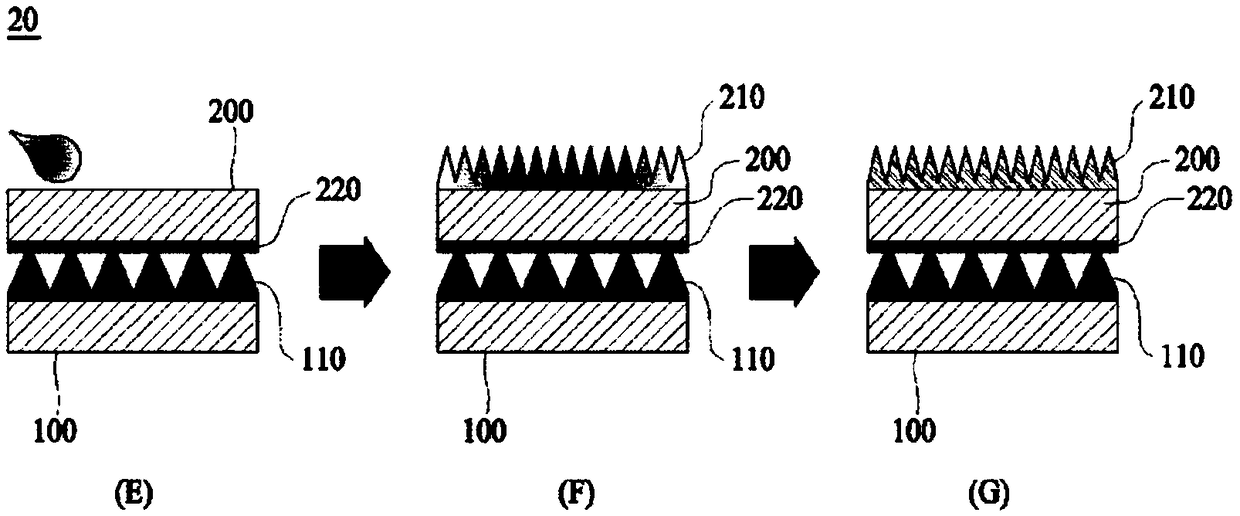

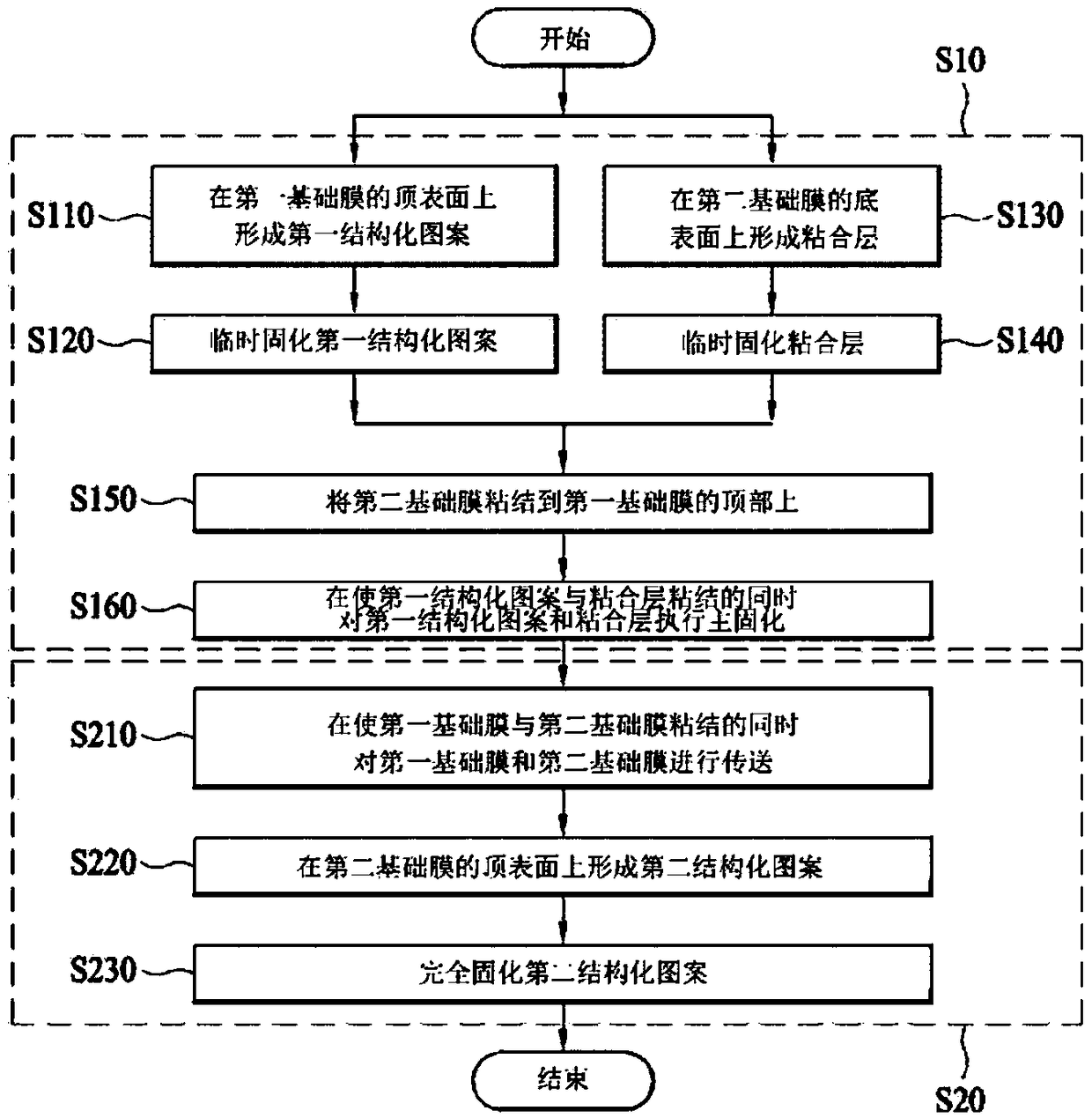

[0042] Exemplary embodiments of a method and apparatus for manufacturing an optical sheet module according to the present invention will be described with reference to the accompanying drawings. However, it is not intended to limit the invention to any particular form but rather to provide a clear understanding of the invention.

[0043] Also, when describing the embodiment of the present invention, the same components are denoted by the same reference numerals and symbols, and further description thereof will be omitted.

[0044] The optical sheet module manufactured according to an embodiment of the present invention may be applied to a backlight unit of a flat liquid crystal display device such as a liquid crystal display (LCD), a light emitting diode (LED), and the like. However, the optical sheet module manufactured according to the present invention is not necessarily limited thereto. The optical sheet module may be applied to a backlight unit of a device other than a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com