Low concentration organic waste gas concentrating, catalyzing and purifying device and use method thereof

A technology for organic waste gas and catalytic purification, applied to chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as incomplete regeneration, decreased adsorption performance, and large fluctuation range of organic matter concentration, so as to control VOCs concentration fluctuations, increase Effects of adsorption time, improvement of safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

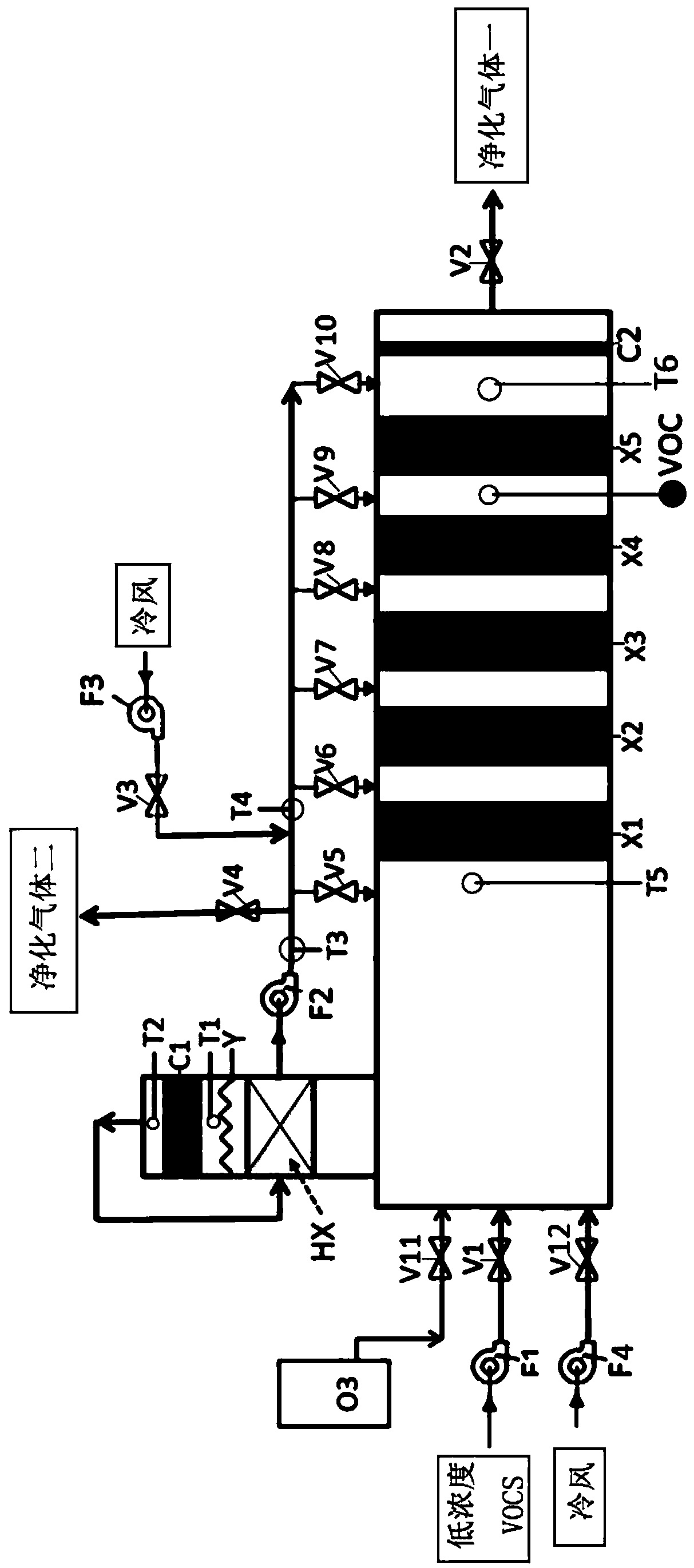

[0028] Such as figure 1 As shown, the low-concentration organic waste gas concentration and catalytic purification device provided by the present invention includes a multi-stage adsorption catalytic bed. The multi-stage adsorption catalytic bed of the present invention is preferably provided with five adsorption catalytic beds, which are respectively the first adsorption catalytic bed X1, the second adsorption catalytic bed The second adsorption catalytic bed X2, the third adsorption catalytic bed X3, the fourth adsorption catalytic bed X4 and the fifth adsorption catalytic bed X5. It also includes a catalytic combustion chamber C1, an ozone decomposition catalytic bed C2, an ozone generator O3, a heat exchanger HX, a preheating chamber Y and four induced draft fans, respectively the first induced draft fan F1 and the second induced draft fan F2, the third induced draft fan F3 and the fourth induced draft fan F4.

[0029] Among them, the first induced draft fan F1 is connect...

Embodiment 2

[0036] Based on the low-concentration organic waste gas concentration catalytic purification device in Example 1, this example adopts the low-concentration organic waste gas concentration-catalytic purification method to concentrate the organic waste gas, wherein the low-concentration organic waste gas concentration air volume is 10000m3 / h (i.e. the first induction The air supply volume of fan F1 is 10000m3 / h), and the concentration of organic matter is 150mg / m3. This method comprises the steps:

[0037] (1) Each of the five adsorption catalytic beds (X1, X2, X3, X4, X5) among the five adsorption catalytic beds is equipped with 1m of honeycomb activated carbon adsorption catalytic material 3 , the honeycomb activated carbon adsorption catalyst material is honeycomb activated carbon loaded with NiO, and the content of NiO is calculated as 2% of the honeycomb activated carbon adsorption catalyst material based on the NiO mass; the noble metal Pd monolithic catalyst supported by ...

Embodiment 3

[0049] Based on the low-concentration organic waste gas concentration catalytic purification device in Example 1, this example uses the low-concentration organic waste gas concentration method in Example 2 to concentrate organic waste gas. The difference is that the honeycomb activated carbon in each adsorption catalytic bed in Example 1 The adsorption catalytic material is replaced by a honeycomb molecular sieve adsorption catalytic material. The adsorption catalyst material of honeycomb molecular sieve is honeycomb activated carbon loaded with NiO, and the content of NiO is calculated as 2% of the adsorption catalyst material of honeycomb molecular sieve based on the mass of NiO; due to different adsorbents, the temperature thresholds are different. During the desorption process, the third temperature sensor T3 Raise and control to 220°C (initial threshold), the first adsorption catalytic bed X1 starts to desorb until the temperature of the fifth temperature sensor T5 reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com