A denitrification system, its control method, and ammonia injection control device

A control method and denitrification technology, applied in ammonia injection control device, denitrification system and its control field, can solve problems such as poor adaptability and complicated control, and achieve the effect of controlling concentration fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. This implementation mode relates to a system embodiment, a method embodiment, and a device embodiment, which are described in sequence below.

[0029] System embodiment:

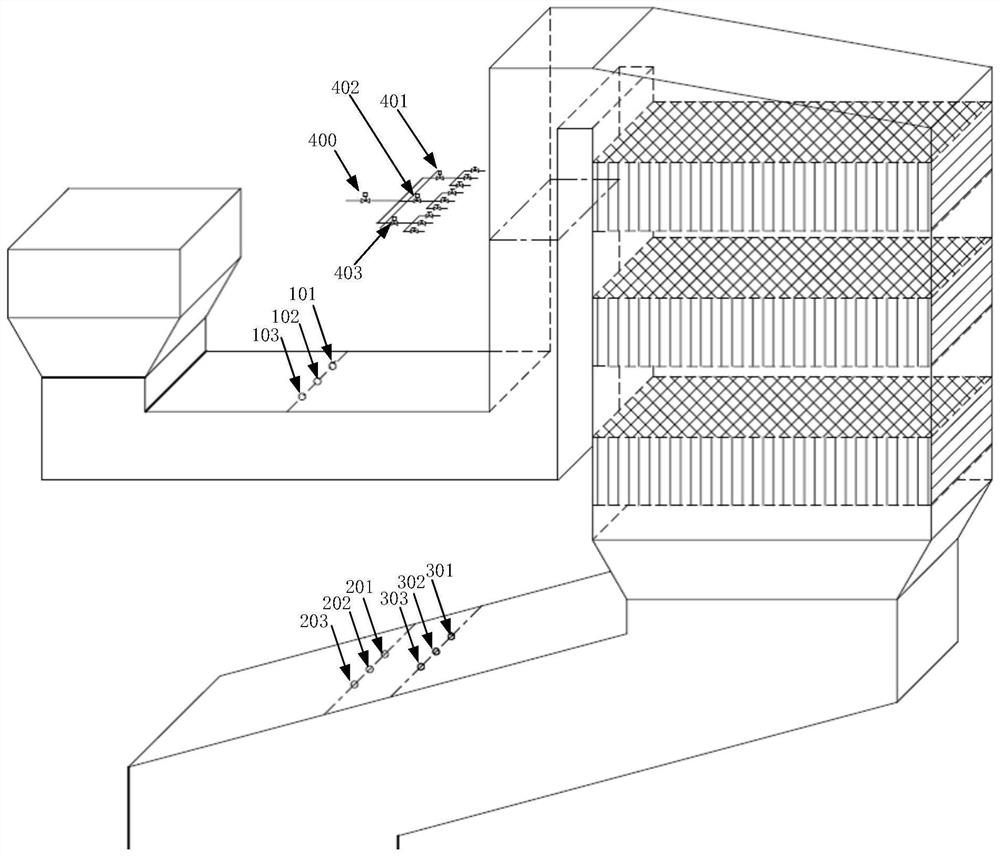

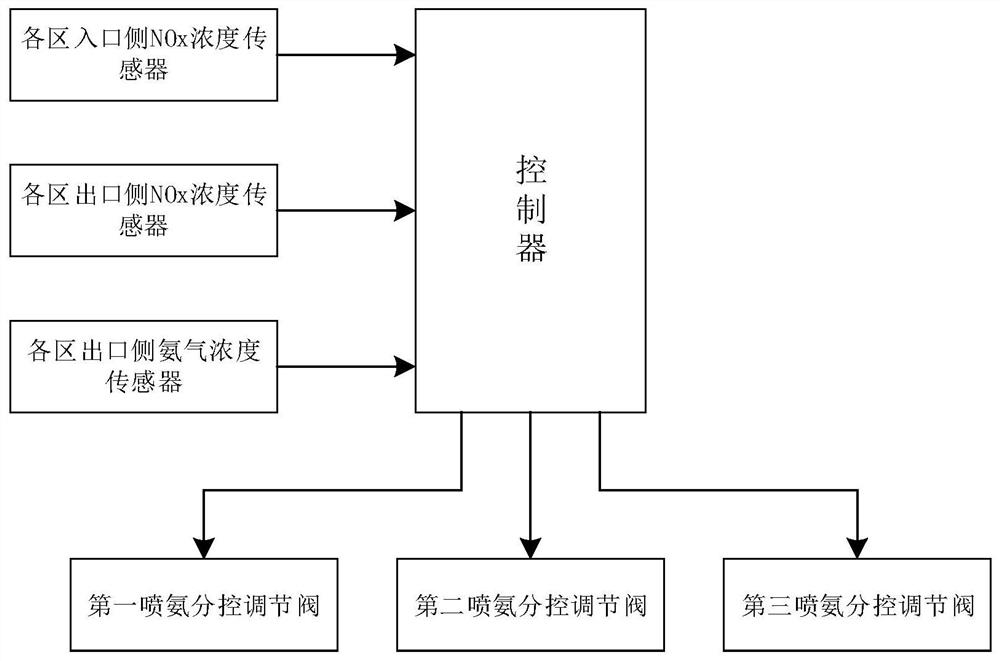

[0030] Such as figure 1 In the shown denitrification system, the denitrification reactor is divided into three zones, zone 1, zone 2 and zone 3; each zone corresponds to zone 1, zone 2 and zone 3 on the inlet side, and zone 1 on the outlet side. NOx concentration sensors 101, 102, and 103 are installed in the first entrance area, the second entrance area, and the third entrance area; the NOx concentration sensors are installed in the first exit area, the second exit area, and the third exit area 201, 202, 203, and concentration sensors 301, 302, 303 of NH3. figure 1 In the denitrification system, there is one ammonia injection master control valve 400 and three ammonia in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com