Nanometer coating material coating device for anti-collision barrier of bridge engineering

A technology of nano-coating and anti-collision guardrails, which is applied in spraying devices, spray booths, etc., can solve the problems of increased construction time, low coating efficiency, and difficulty in coating, and achieves improved coating efficiency, shortened construction time, and uniform spraying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

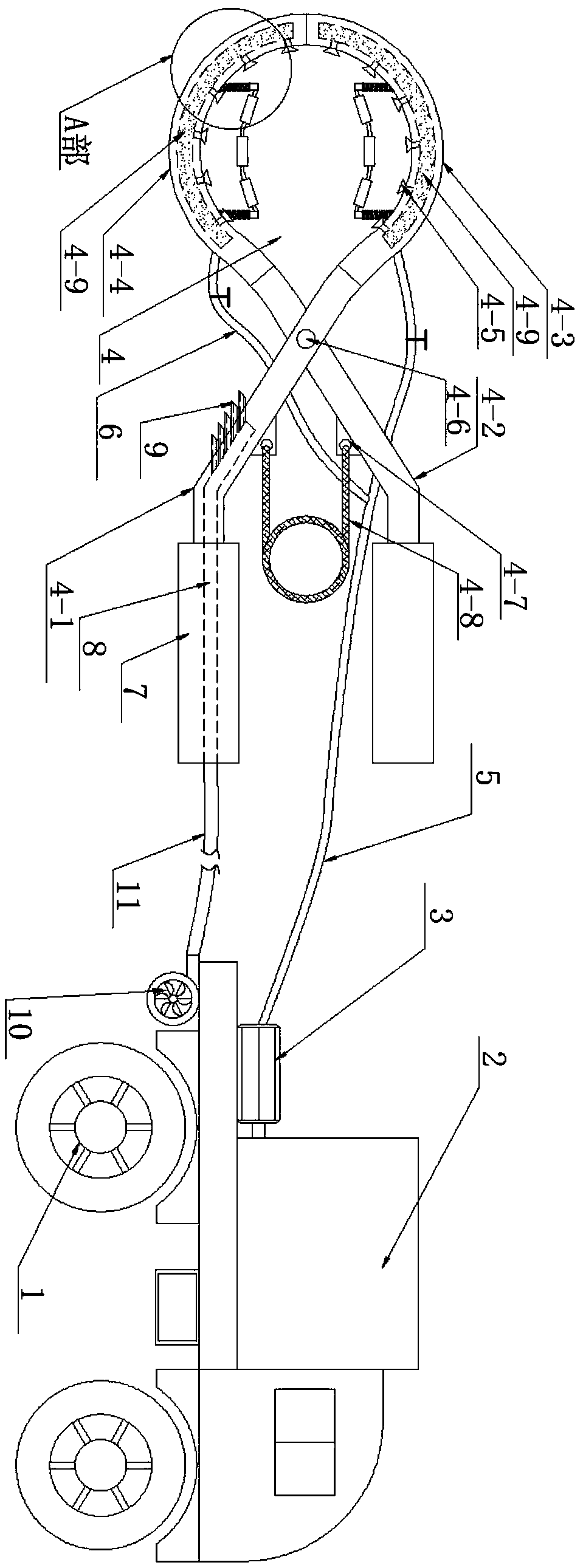

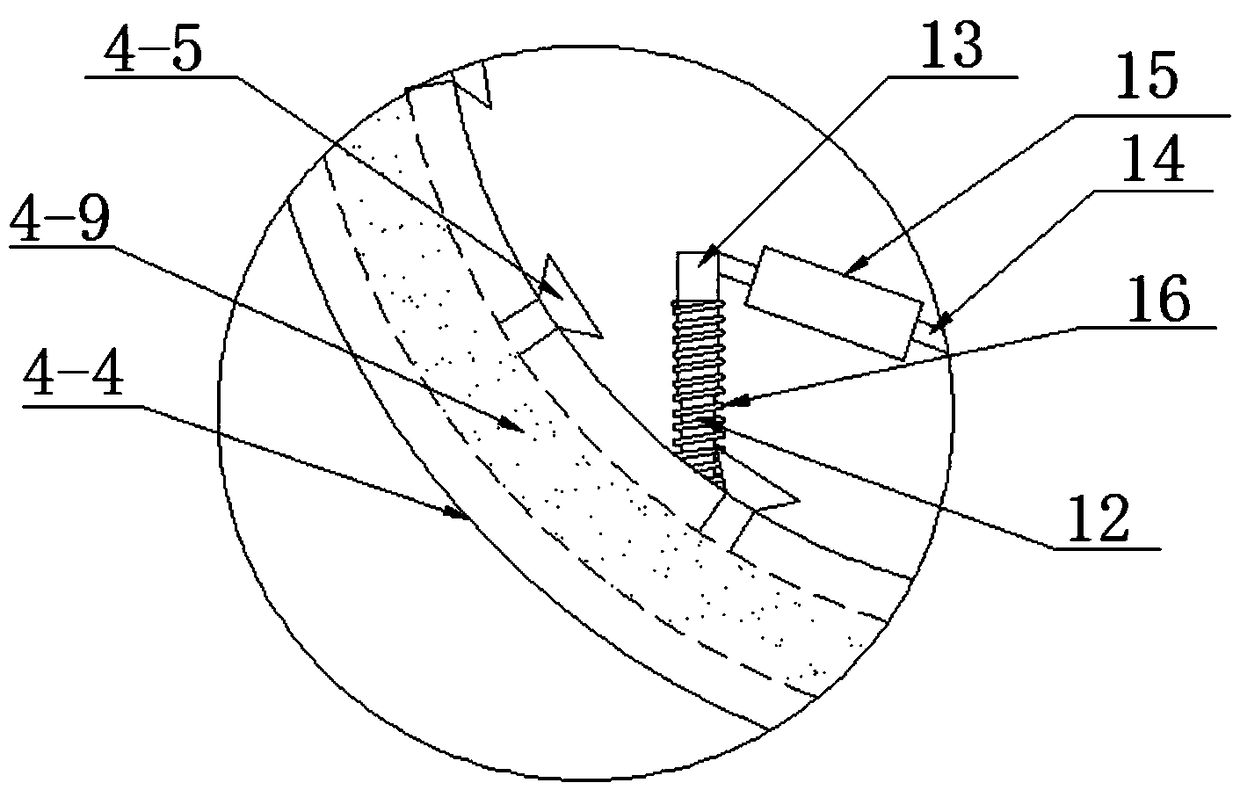

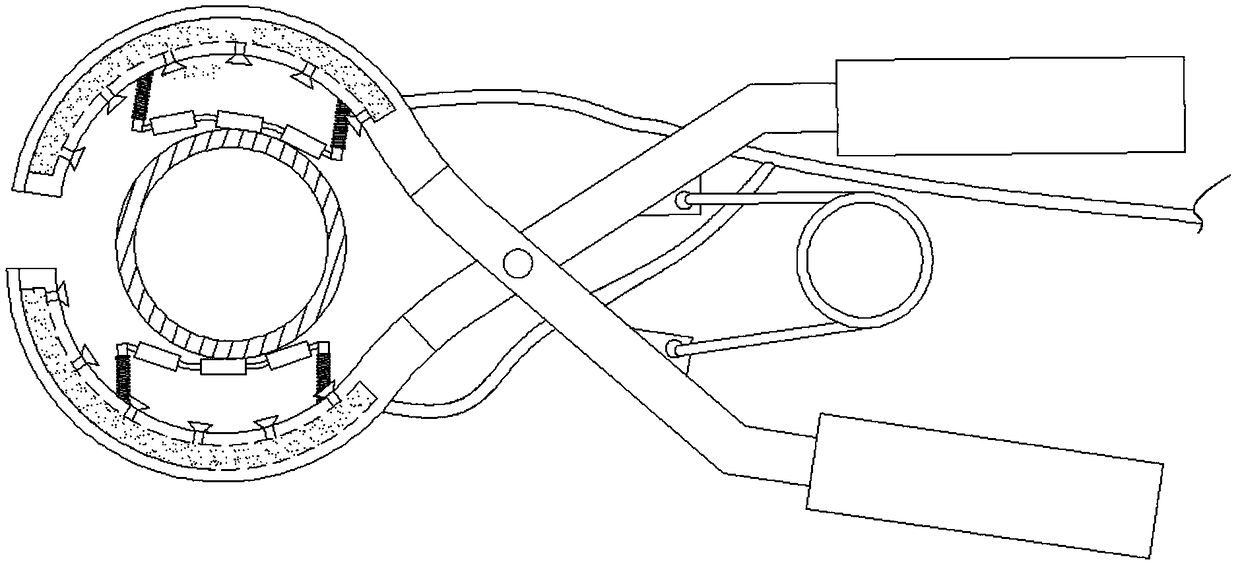

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] see as Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes engineering vehicle 1 (what adopts is the small cargo truck in the prior art), paint box 2 (length is 1500mm, width is 1000mm, height is 1500mm), pumping Suction pump 3 (300PNS-50 single-suction impurity pump is used); paint box 2 is fixedly installed on the bearing plate on the left side of engineering vehicle 1, and the interior of paint box 2 is filled with nano-coating, and the paint box 2 itself The gravity is heavy, and it is not easy to slide when placed on the bearing plate; the engineering vehicle 1 on the left side of the paint tank 2 is fixed with a suction pump 3 through bolts, and the suction pump 3 is connected to the battery of the engineering vehicle 1 through a power line. The control switch of 3 is set on the central control inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com