Bipolar plate coating device

A bipolar plate and paste coating technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems affecting the performance of the plate, short circuit, affecting battery life, etc., and achieve the effect of cost saving and efficiency improvement

Inactive Publication Date: 2019-02-15

GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] When the above-mentioned platen mechanism compacts the paste on the grid frame, there will be such a problem: when the platen platen mechanism is pressing the paste on the grid frame, there will be residual paste on the outer frame of the grid frame. It will not only affect the appearance of the plate, but also affect the performance of the plate, and even cause a short circuit, and the remaining powder from the remaining paste will affect the life of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

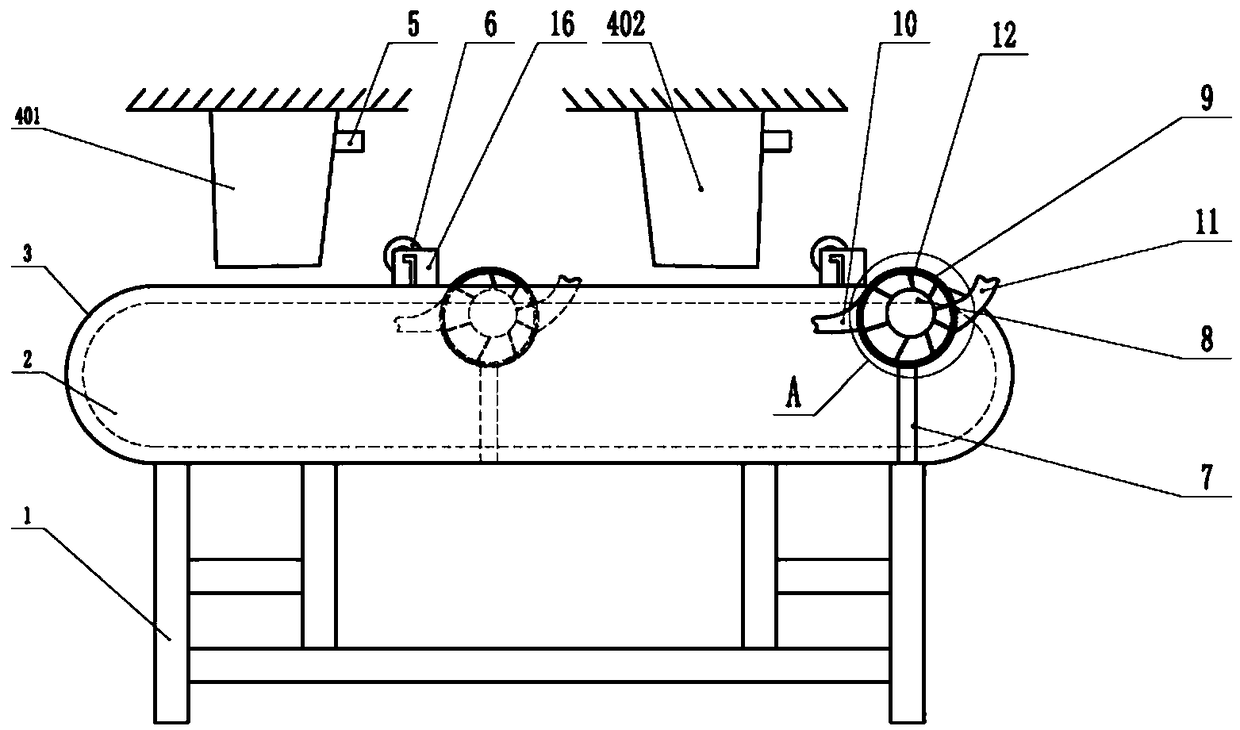

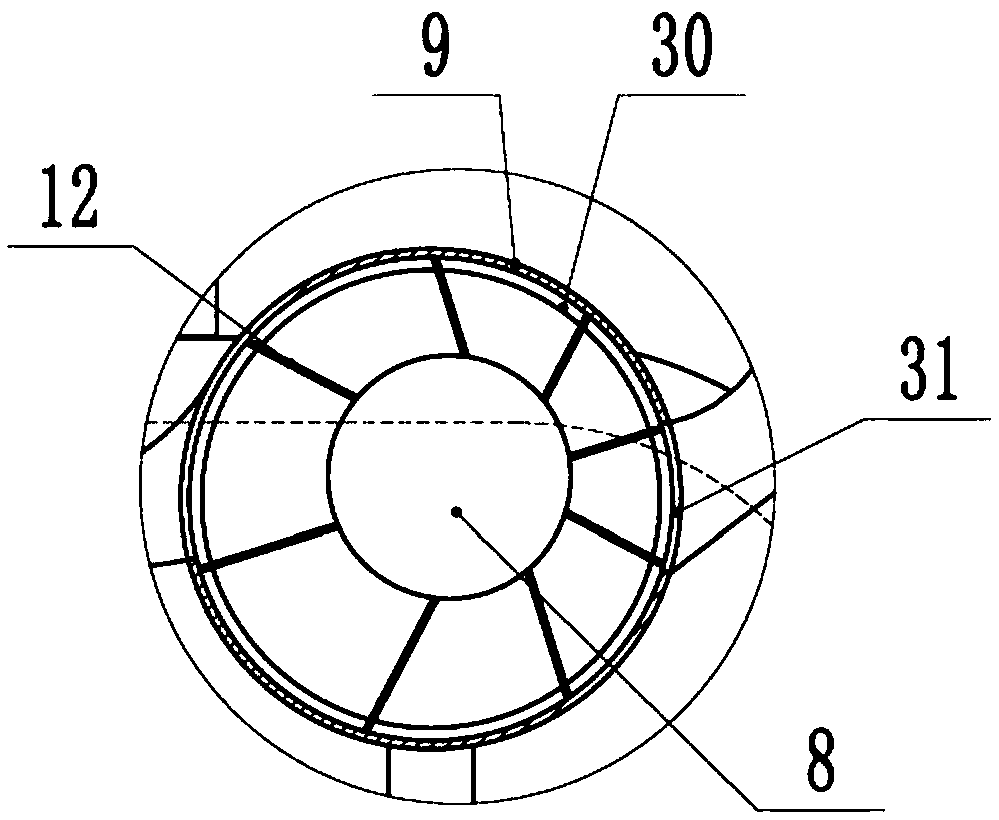

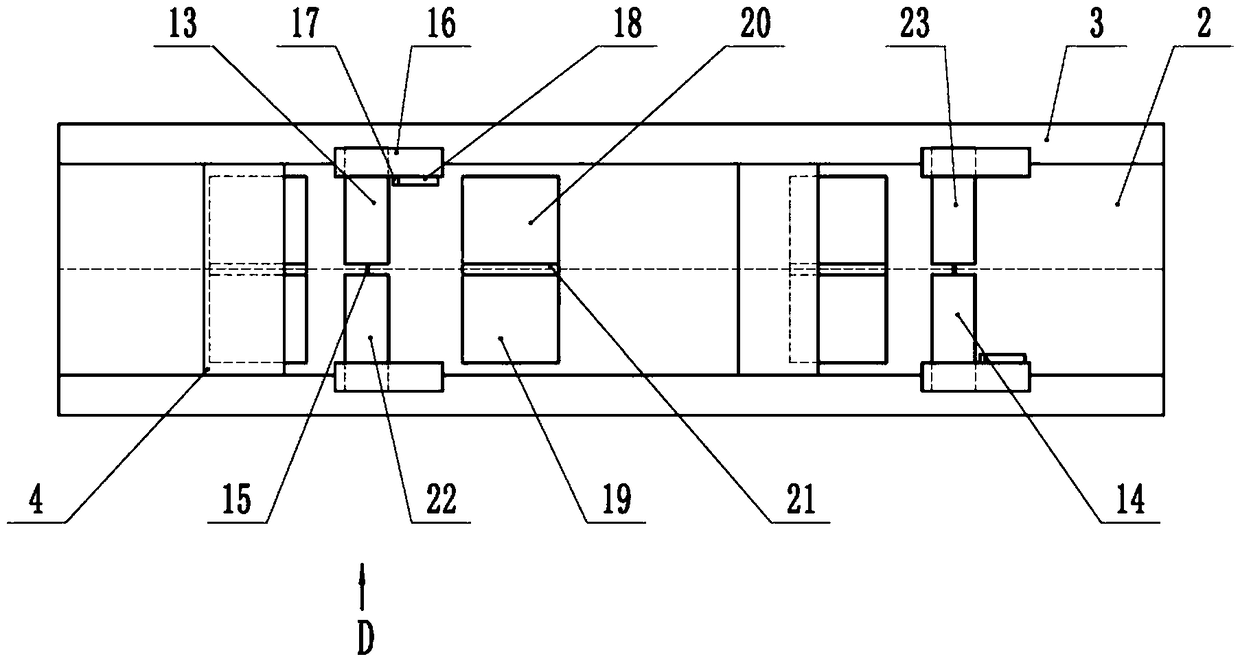

The invention belongs to the technical field of battery pole plate production, and particularly discloses a bipolar plate coating device. The device comprises a rack, a conveying device which is installed on the rack and a paste coating hopper which is arranged above the conveying device, wherein the conveying device comprises a conveying frame and a conveying belt, a paste pressing device used for pressing a paste body on a pole plate is arranged on the conveying frame, a scraper which is used for scraping residual paste of a frame of the polar plate is arranged on the paste pressing device,the scraper is connected with a feeding groove for containing the residual paste, a feeding groove communicates with a cylinder, the cylinder is located below the paste pressing device, a rotating shaft is arranged in the cylinder, a rotating unit is arranged on the rotating shaft, a plurality of groups of rotating units are arranged, the plurality of groups of rotating units are uniformly distributed in the circumferential direction of the cylinder, and the axis of the rotating shaft is eccentrically arranged with the axis of the cylinder, so that spaces with different sizes are formed amongthe rotating units; and a discharging hole is formed in the cylinder. According to the device, a positive plate and a negative plate can be simultaneously coated with paste, the residual paste on theframe of the positive plate and the frame of the negative plate can be recycled, so that the residual paste can be recycled.

Description

technical field [0001] The invention belongs to the technical field of battery pole plate production, in particular to a bipolar plate pasting equipment. Background technique [0002] Batteries have been widely used because of their low cost, high voltage, rich raw materials and energy-saving features. Batteries are mainly composed of plates, electrolytes, separators, casings, etc., among which the plates of batteries are in the composition of batteries. part plays an important role. The chemical reaction that occurs during the charging and discharging process of the storage battery mainly depends on the reaction between the active material on the plate and the electrolyte. The plate is divided into a positive plate and a negative plate, both of which are composed of grids and The active material on the positive plate is lead dioxide (PI), which is dark brown; the active material on the negative plate is spongy pure lead (Ph), which is blue-gray. The active material is adj...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05C5/02B05C13/02B05C11/02B05C11/10B05C11/11

CPCB05C5/0208B05C11/025B05C11/1039B05C11/11B05C13/02

Inventor 何幸华黎少伟李政文何可立马俊

Owner GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com