Spindle cooling double-circulation device of multi-wire sawing machine

A multi-wire cutting machine and double-circulation technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of unstable control temperature, not obvious cooling, deformation of bearings and bearing seats, etc., and achieve rapid cooling High efficiency, guaranteed service life and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

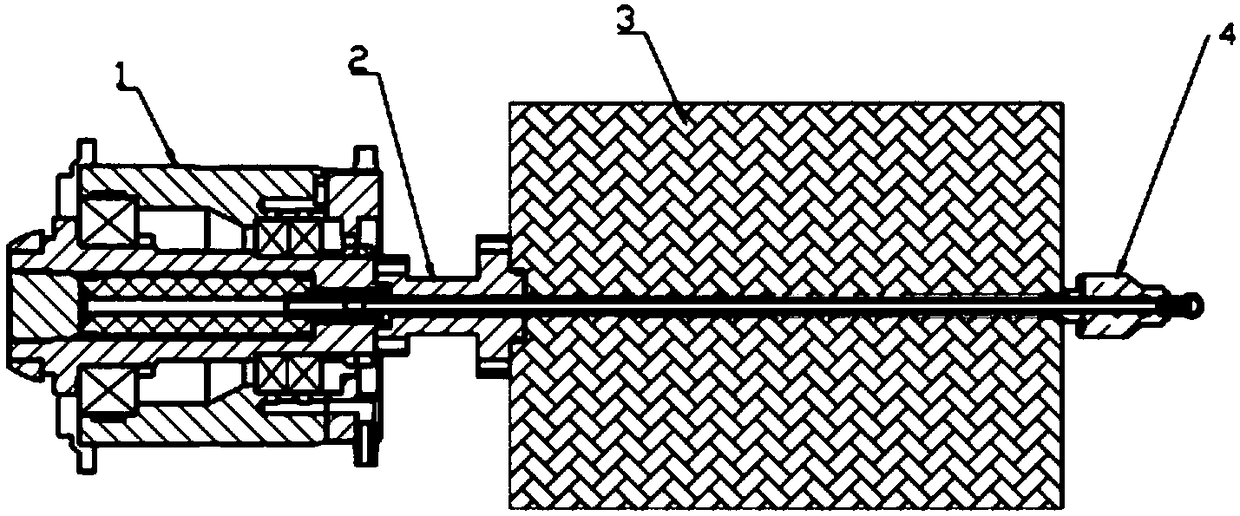

[0020] Referring to the accompanying drawings, a spindle cooling dual circulation device for a multi-wire cutting machine includes a spindle assembly 1, a connecting shaft 2, a driving motor 3 and a rotary joint assembly 4, and the spindle assembly 1 is connected to the driving motor 3 through the connecting shaft 2;

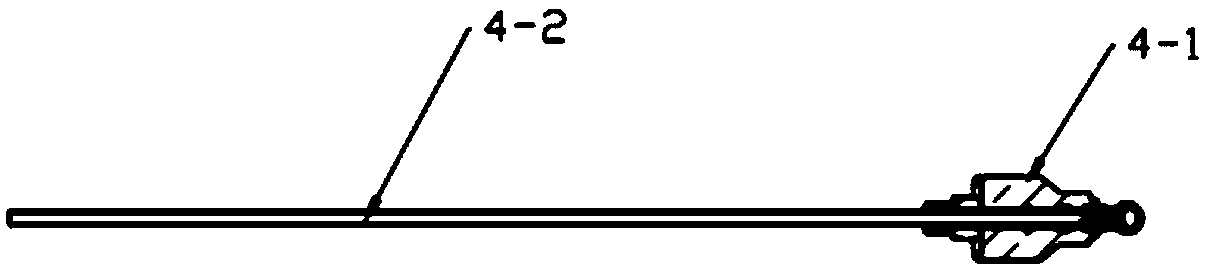

[0021] The rotary joint assembly 4 includes a rotary joint 4-1 and a connecting pipe 4-2, the rotary joint 4-1 is fixed on the driving motor 3, the connecting pipe 4-2 is installed on the rotary joint 4-1, and passes through The driving motor 3 and the connecting shaft 2 are connected to the main shaft assembly 1;

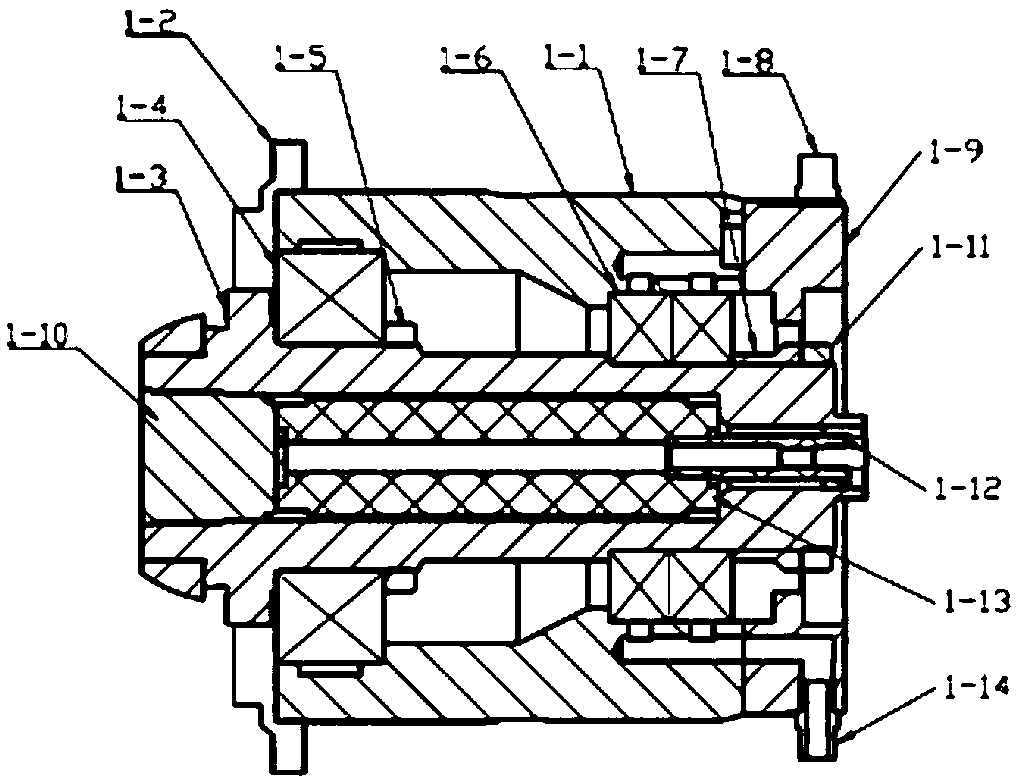

[0022] The spindle assembly 1 includes a bearing seat 1-1, a front gland 1-2, a spindle 1-3, a bearing I1-4, a nut I1-5, a bearing II1-6, a top sleeve 1-7, a joint I1-8, Rear end gland 1-9, end cap 1-10, nut II 1-11, small sleeve 1-12, central large sleeve 1-13 and joint II 1-14; the main shaft 1-3 is a hollow shaft, so The large central sleeve 1-13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com