Automatic open-mouth bag discharging device with air expansion sealing function for bag mouth

An automatic unloading and open bag technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of easily damaged packaging bags, waste of materials, affecting the working environment, etc., and achieve the effect of saving logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0022] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and rear are based on the position status of the accompanying drawings, and thus cannot be interpreted as providing guidance for the present invention. Special restrictions on technical solutions.

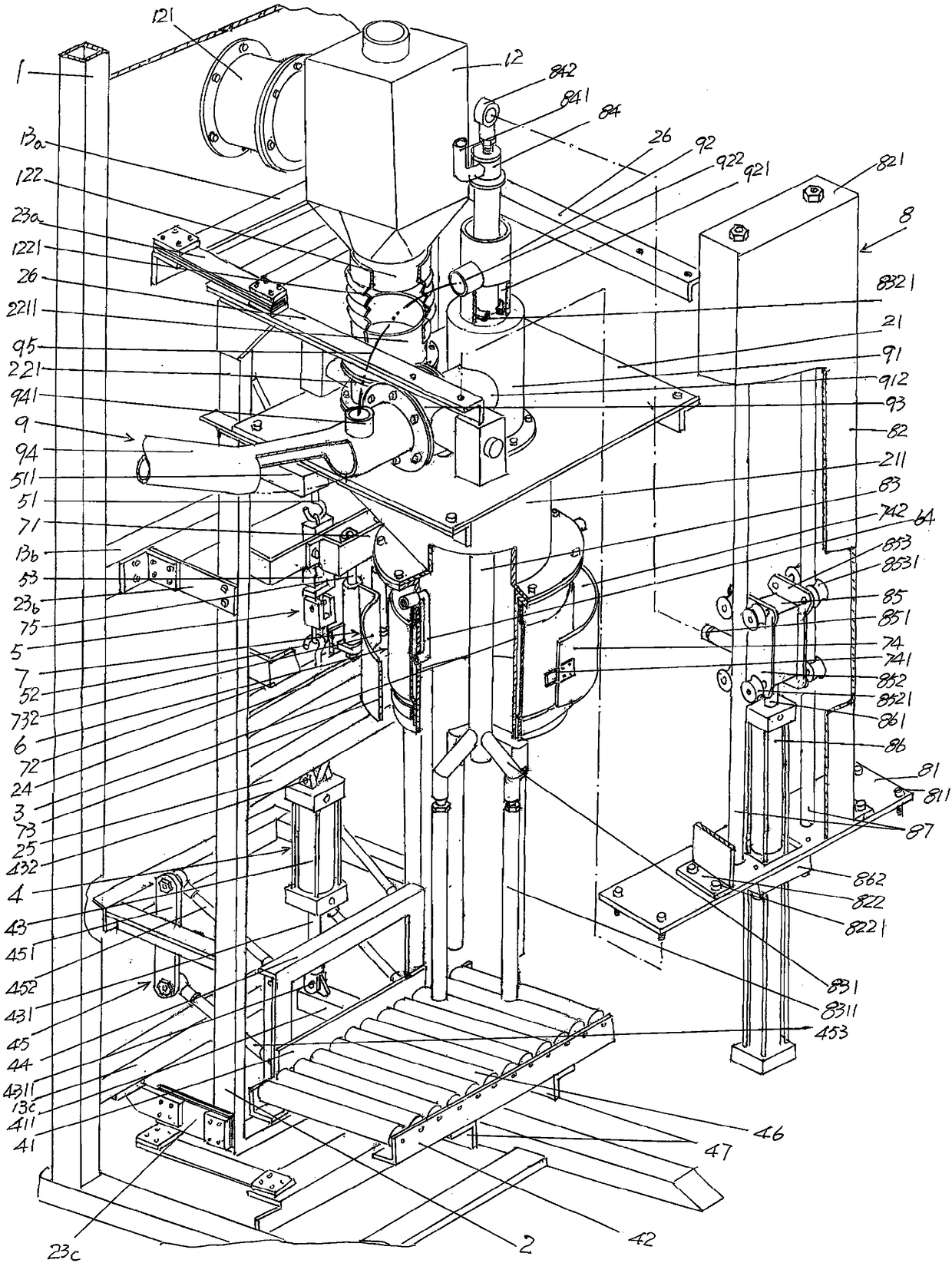

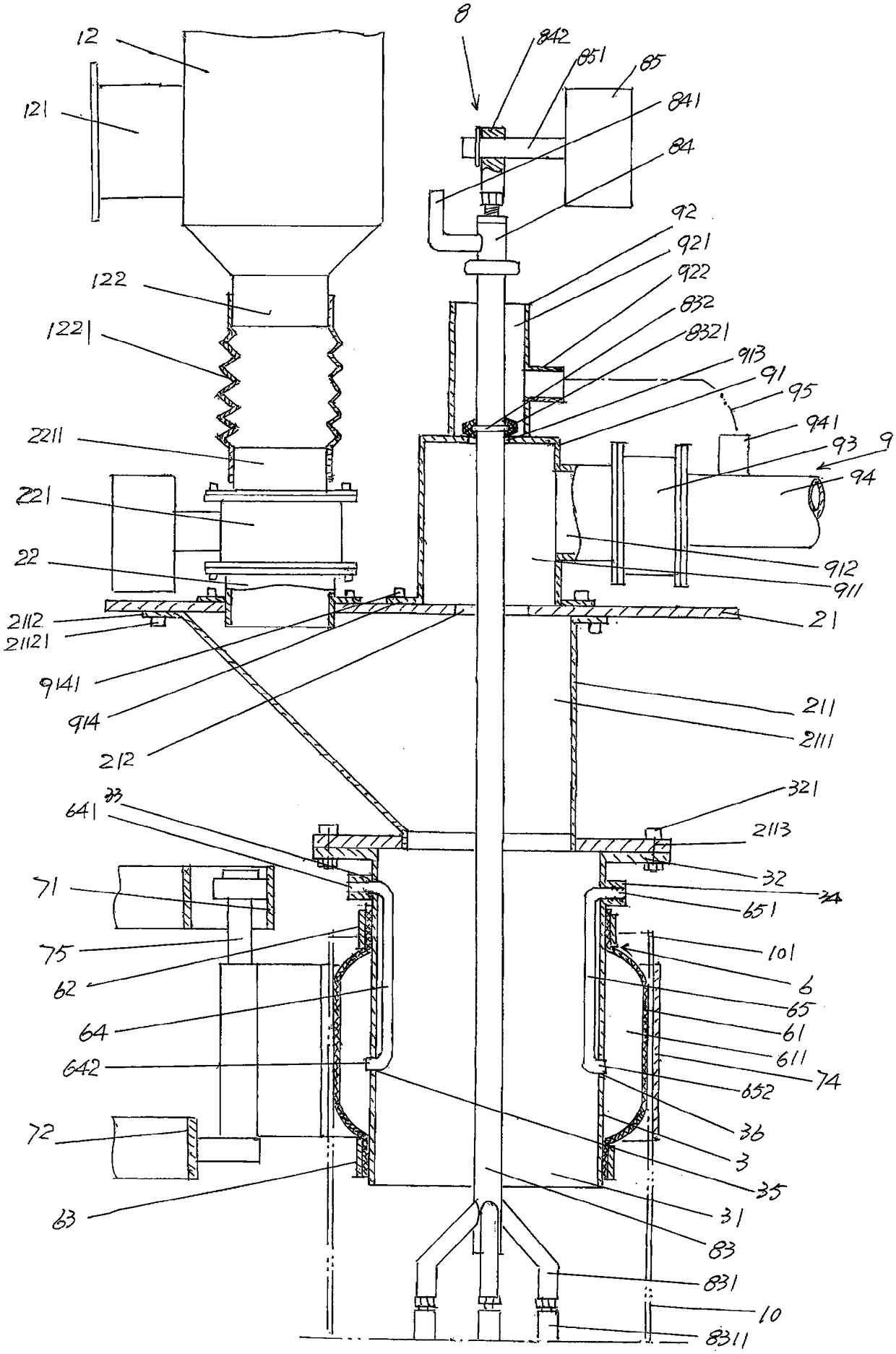

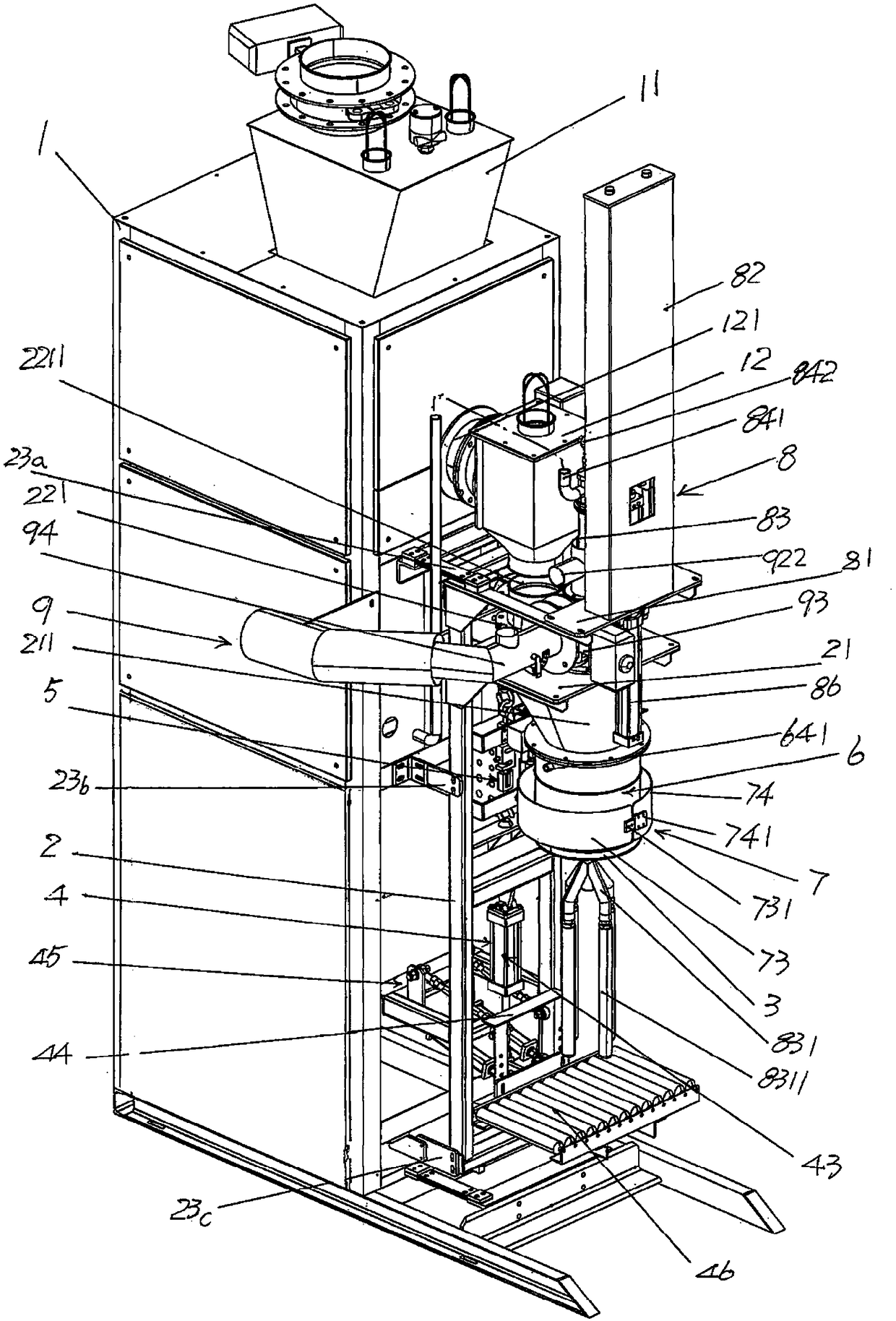

[0023] See Figure 1 to Figure 3 , shows a frame 1, and a storage box 11 is arranged on the top of the frame 1 ( image 3 shown), and a feed tube 12 is arranged on the upper right side of the frame 1, and the feed tube 12 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com