Horizontal moving type support separating mechanism, support separating machine and method for separating plastic supports

A technology of horizontal movement and plastic support, which is applied in the field of palletizing machines, can solve the problems of large range of motion, intermittent movement of the cylinder, and slow palletizing speed, etc. The effect of moving right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

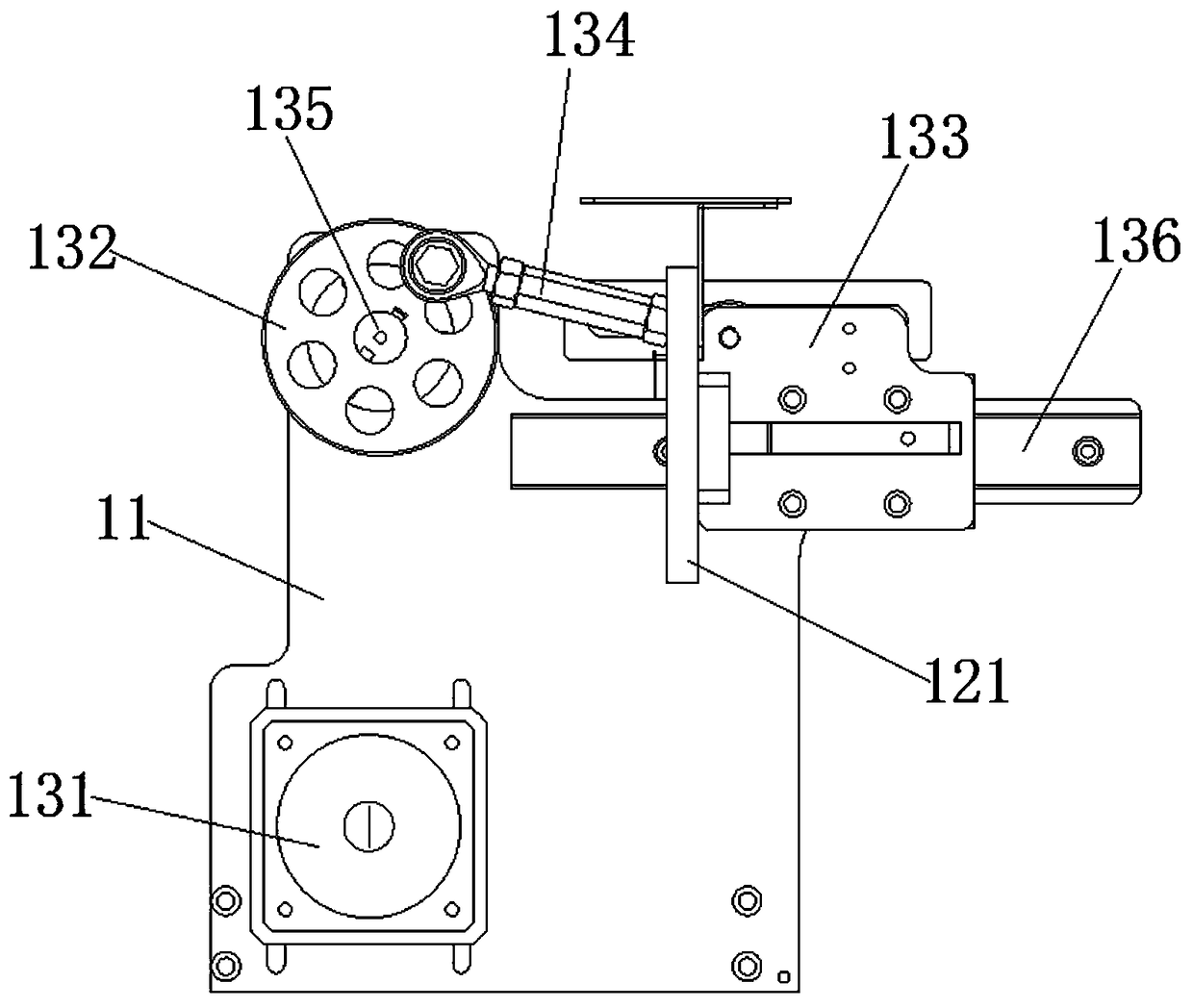

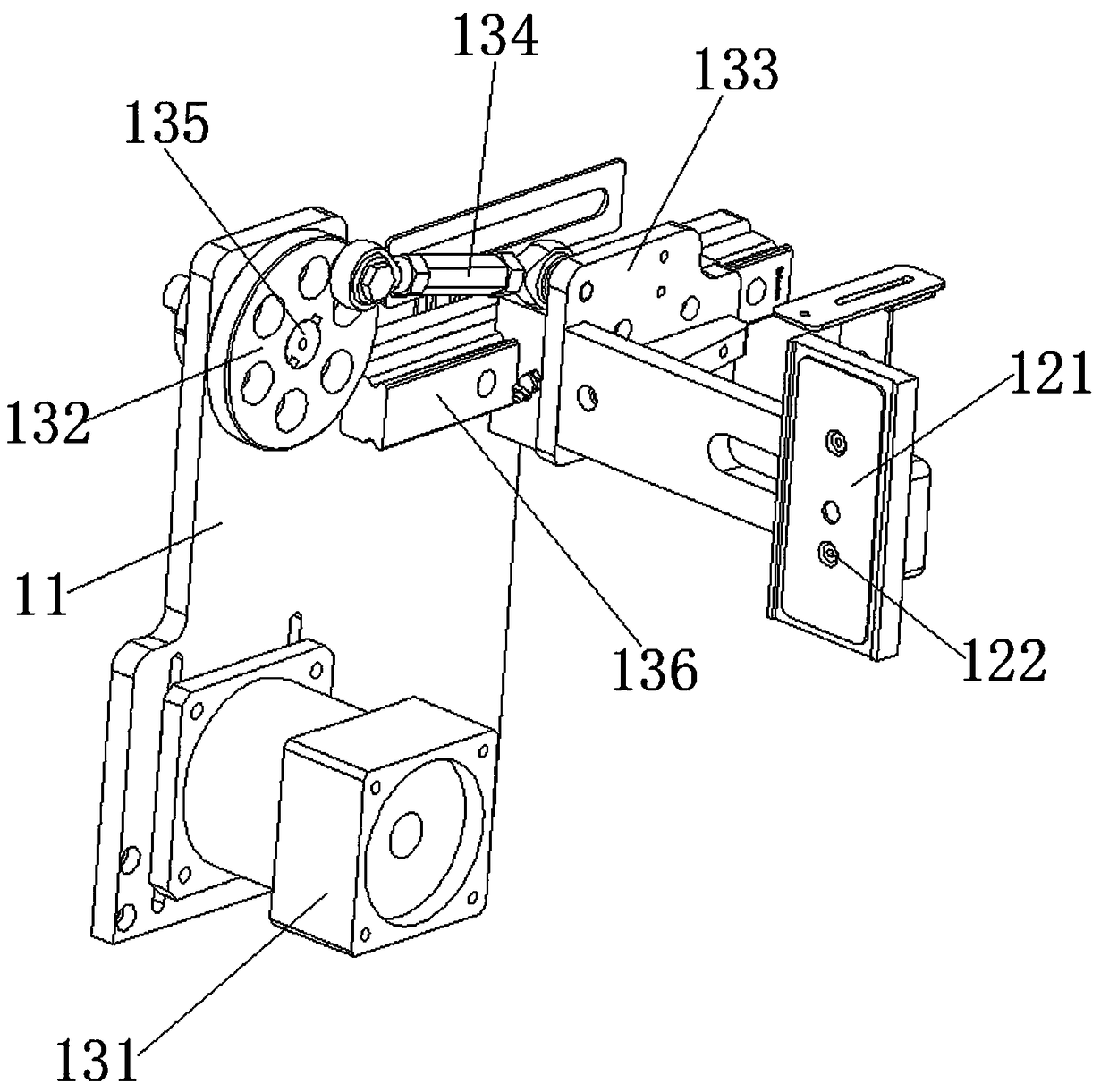

[0039] see figure 1 and figure 2 .

[0040] The horizontally movable sub-supporting mechanism provided by the embodiment of the present invention includes a mounting plate 11, a curved slideway and an adsorption block 121. The mounting plate 11 is used to be fixed on the sub-supporting machine. The adsorption block 121 is provided with an air hole, and the air hole is connected to a negative pressure source. , the adsorption block 121 is used to absorb the plastic trays and move a certain distance before releasing them. The released plastic trays fall on the curved surface slideway, and then reach the conveyor belt from the curved surface slideway, thereby separating the plastic trays one by one.

[0041] The mounting plate 11 is provided with a mobile assembly for driving the adsorption block 121 to move left and right. The mobile assembly includes a motor 131, a rotating part 132 and a slide block 133 fixed on the mounting plate 11. The rotating part 132 is connected with ...

Embodiment 2

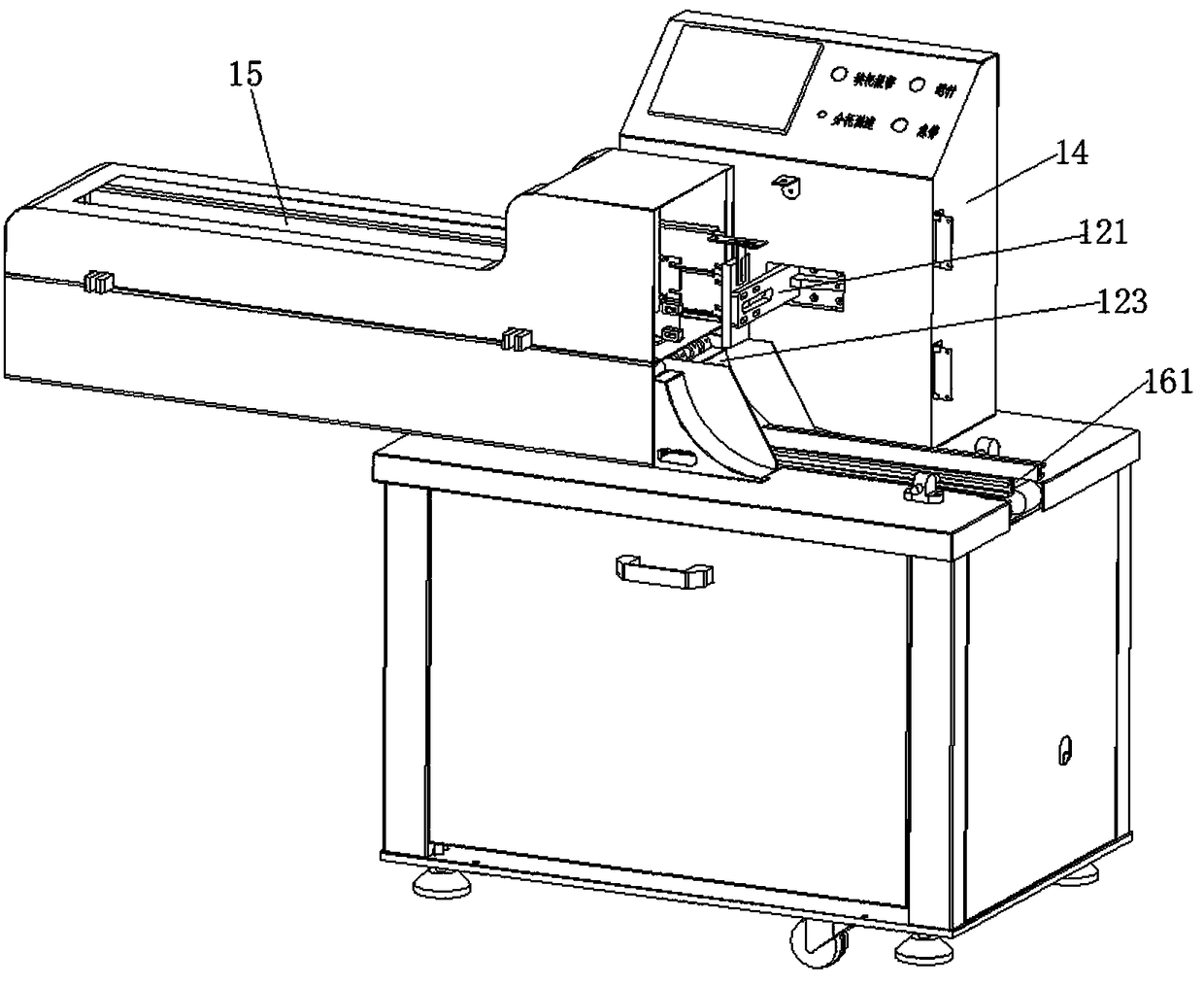

[0047] see Figure 3 to Figure 6 .

[0048] The sub-palletizing machine provided by the embodiment of the present invention includes a cabinet 14, in which the horizontally movable sub-palletizing mechanism in Embodiment 1 is installed, and the adsorption block 121 on the horizontally mobile sub-palletizing mechanism is located outside the cabinet 14, and is placed outside the cabinet 14. One side of 14 is provided with material storage box 15, puts the plastic tray stacked together in material storage box 15, the adsorption surface of adsorption block 121 faces the outlet of material storage box 15, and adsorption block 121 moves to the left to storage box A plastic holder can be adsorbed at the outlet of 15.

[0049] The curved surface slideway 123 is arranged below the adsorption block 121, and a conveyor belt 161 is provided at the end of the curved surface slideway 123, and a sub-pallet accumulation detection mechanism is provided on the conveyor belt 161. The sub-pallet...

Embodiment 3

[0056] see Figure 7 .

[0057] The method for separating the plastic holder provided by the embodiment of the present invention adopts the separating machine in embodiment 2, comprising the following steps:

[0058] Step 31: The motor drives the adsorption block to move to the left close to the outlet of the storage box, the surface of the adsorption block fits on the outermost plastic holder and generates negative pressure to absorb the plastic holder;

[0059] Step 32: The motor drives the adsorption block to move to the right, the negative pressure on the surface of the adsorption block disappears, and the plastic support falls on the curved slideway.

[0060] Step 33: The plastic support slides down to the conveyor belt along the curved slideway.

[0061] In step 31, when the adsorption block moves to the leftmost position, the surface of the adsorption block is attached to the outermost plastic holder of a stack of plastic holders, and at this time, the air hole on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com