Efficient feed baler

A feed and high-efficiency technology, applied in packaging, solid materials, transportation packaging, etc., can solve the problems of low feed packaging efficiency, achieve the effects of improving feed packaging efficiency, preventing feed spillage, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

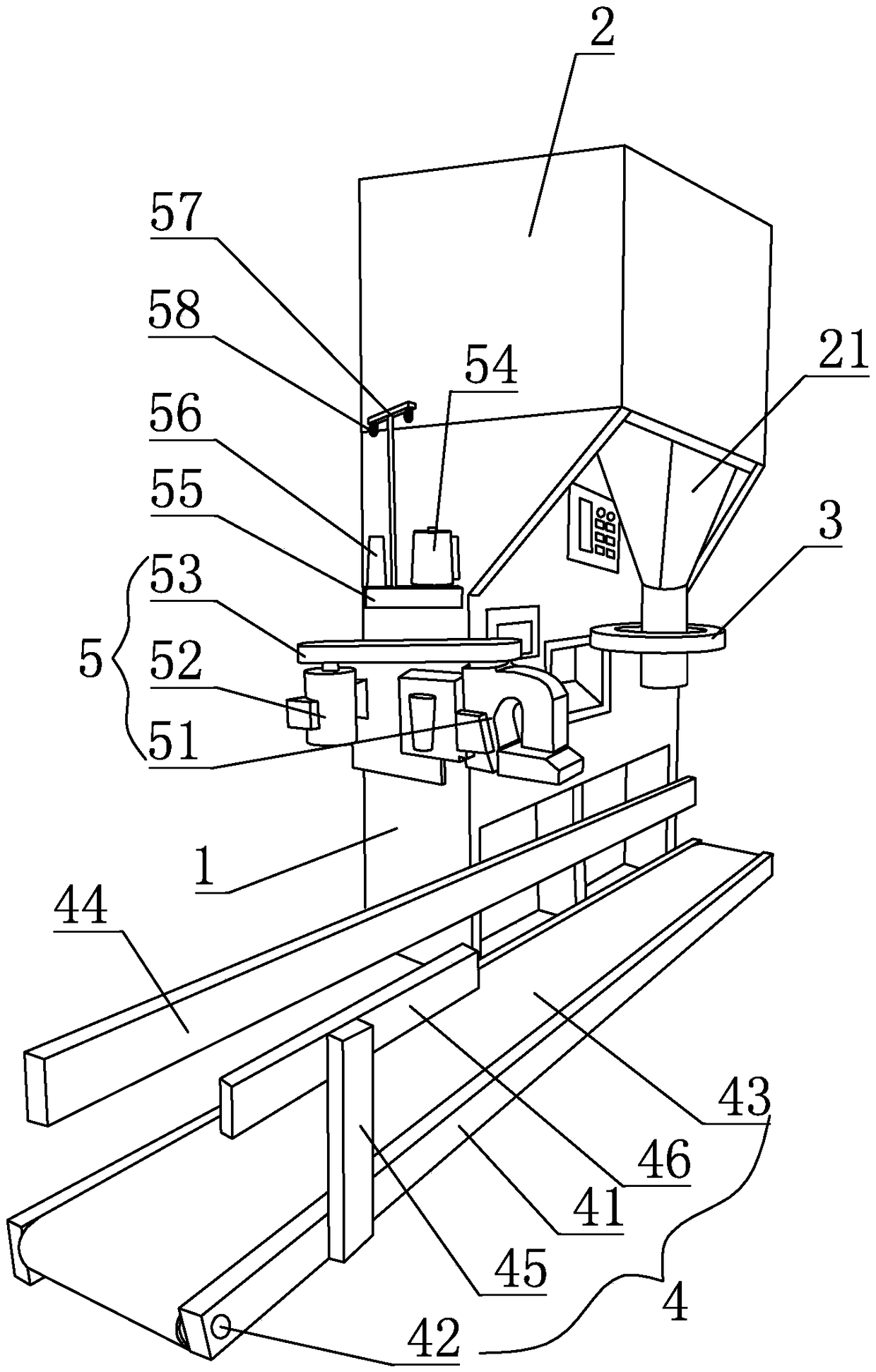

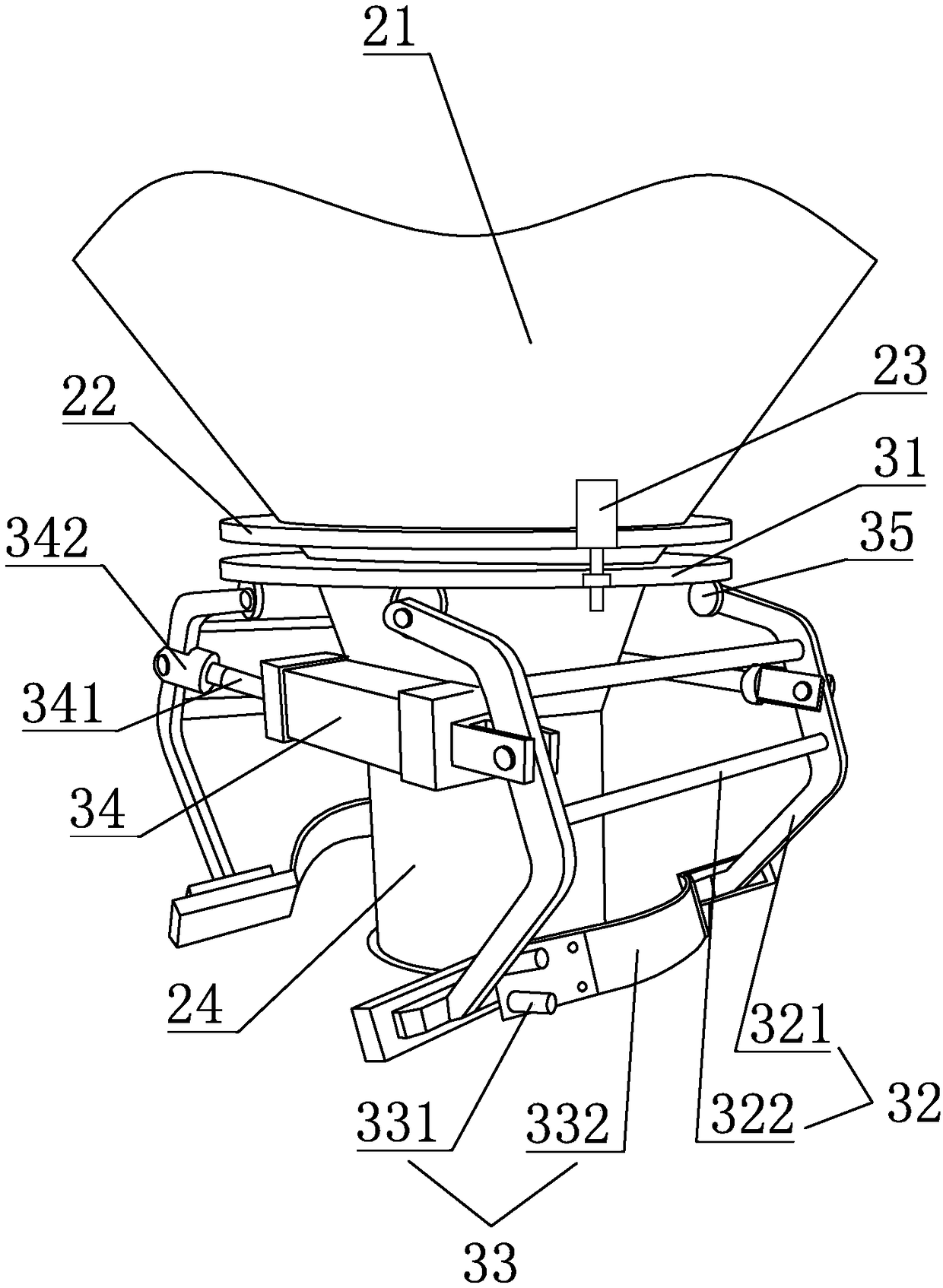

[0014] refer to Figures 1 to 2 , a high-efficiency feed baler of the present invention includes a body 1, a feed bin 2 arranged on the top and a control system, the bottom of the feed bin 2 is provided with a conical discharge hopper 21 placed on the front side of the body 1, the cone A positioning ring 22 is fixed at the lower part of the shaped discharge hopper 21, and a discharge guide cylinder 24 and a pneumatic bag clamp 3 are suspended on the positioning ring 22 by at least three load cells 23 evenly arranged along its circumference. The upper end of the material guide cylinder 24 is set as a funnel and is movably sleeved on the lower end of the conical discharge hopper 21. The lower part of the conical discharge hopper 21 is also provided with a discharge valve, and the front side of the body 1 under the discharge guide cylinder 24 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com