Breaking piece conveying mechanism and small breaking piece device

A conveying mechanism and slivers technology, which is applied in the direction of conveyors, conveyor objects, lighting and heating equipment, etc., can solve the problems of easy loose pieces of products, product scratches, and debris generation, so as to reduce the probability of being scratched, Effect of reducing debris and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 of the present invention provides a split conveying mechanism.

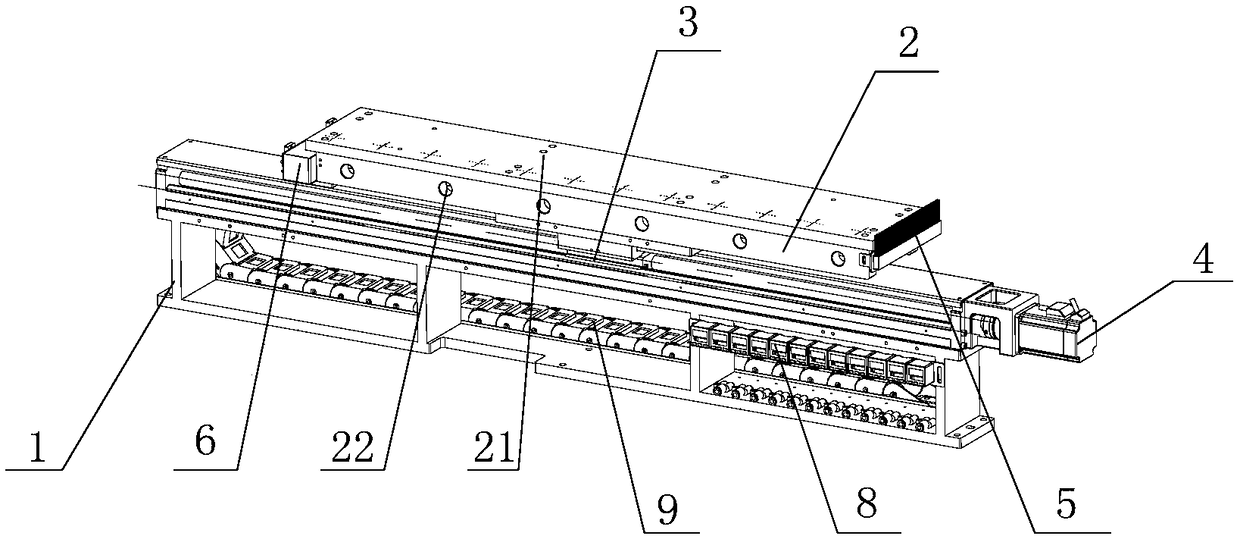

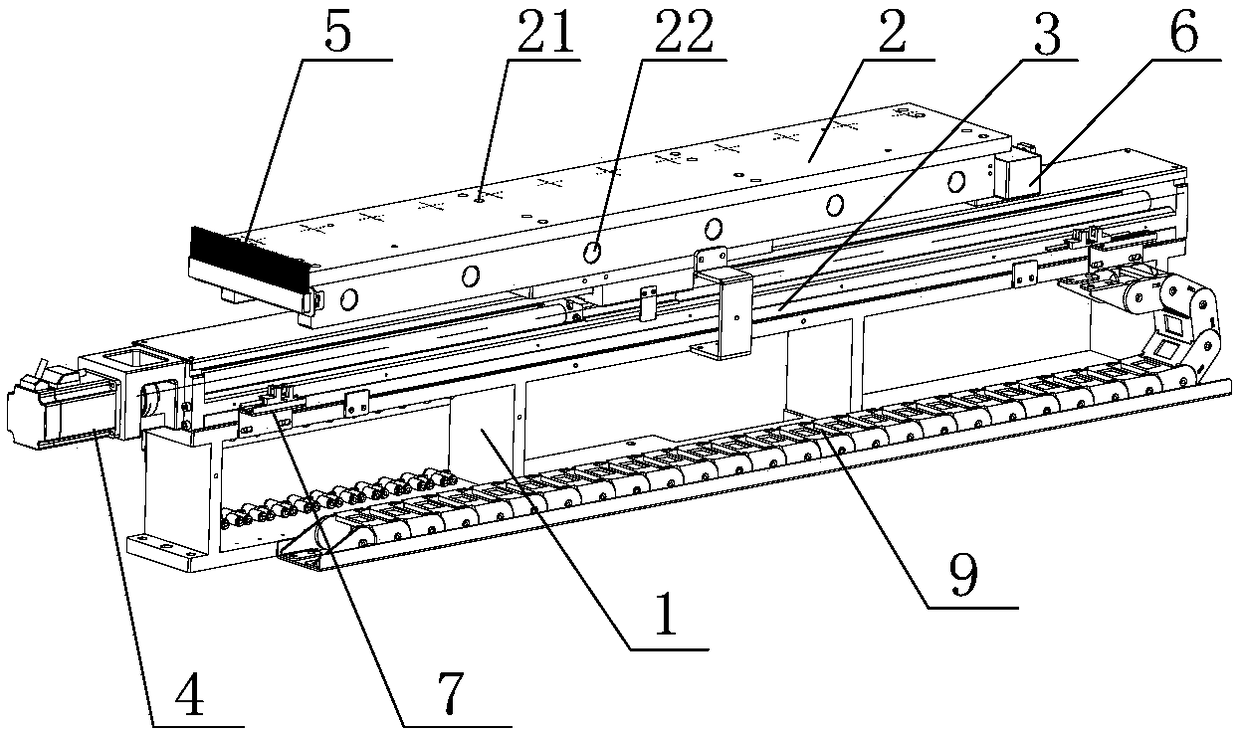

[0043] figure 1 It is a schematic diagram of the overall structure of the split delivery mechanism provided by the embodiment of the present invention from a perspective; figure 2 It is a schematic diagram of the overall structure of the split conveying mechanism provided by the embodiment of the present invention from another perspective.

[0044] refer to figure 1 and figure 2 , the split delivery mechanism includes a support base 1 , a delivery platform 2 , a precision positioning module 3 and a servo motor 4 .

[0045] Specifically, the precision positioning module 3 is arranged on the support base 1; the delivery platform 2 is fixedly connected to the top of the slider of the precision positioning module 3; the servo motor 4 is used to drive the slider of the precision positioning module 3 to drive the delivery platform 2 Do linear reciprocating movement in the horizontal direction; a...

Embodiment 2

[0059] Embodiment 2 of the present invention provides a device for splitting small pieces, including the split delivery mechanism provided in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com