Cloth supporting mechanism of cloth plaiting machine

A technology of a support mechanism and a yarder, which is applied in the field of yarders, can solve the problems that the cloth is easily dragged away by the yarder rod and affect the yardage effect, etc., so as to improve the stacking effect, enhance the protection effect, and reduce the frictional force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described with reference to the accompanying drawings.

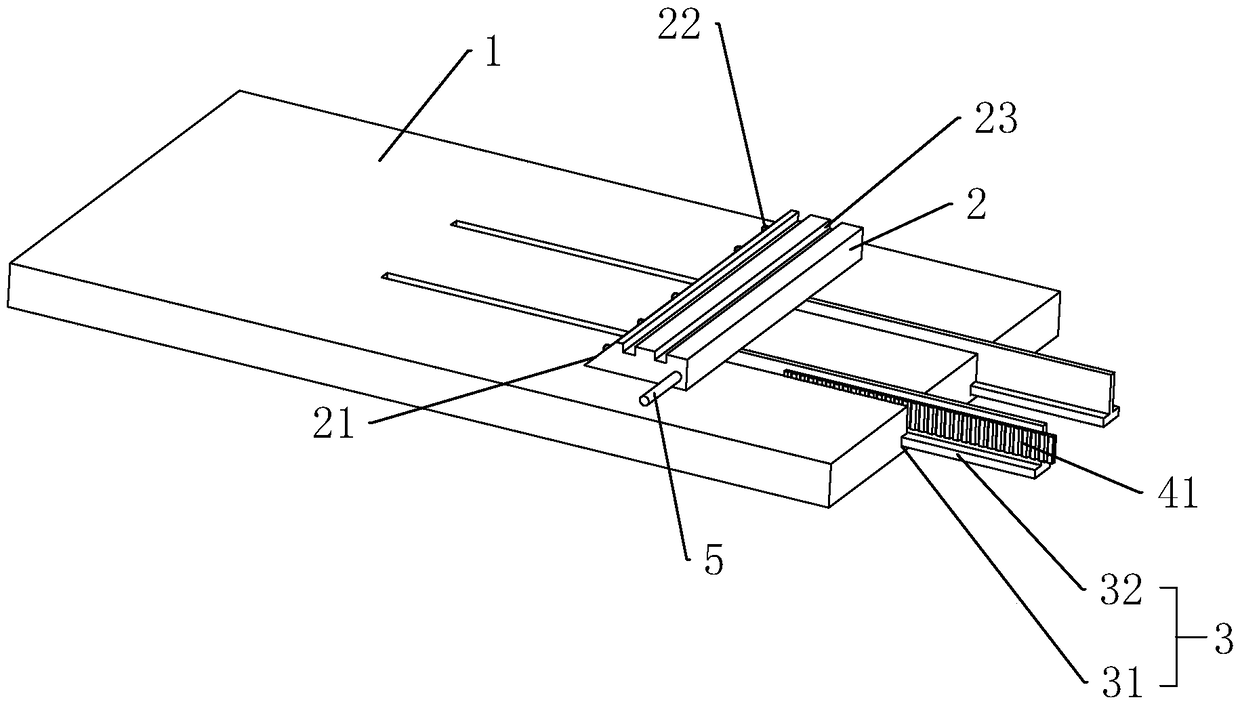

[0024] A cloth supporting mechanism of a cloth coder includes a working platform 1 for stacking cloth. A support plate 2 is slidably connected to the upper surface of the working platform 1, and an end of the support plate 2 close to the cloth is provided with a guide slope 21 for placing cloth.

[0025] In order to reduce the frictional force between the guiding slope 21 and the cloth, a plurality of support wheels 22 are rotatably connected to the guiding slope 21 . Support wheel 22 adopts plastics to make.

[0026] In order to increase the friction between the support plate 2 and the cloth, so that the cloth can be placed on the support plate 2 more stably, a plurality of anti-slip grooves 23 are provided on the side of the support plate 2 facing away from the working platform 1 .

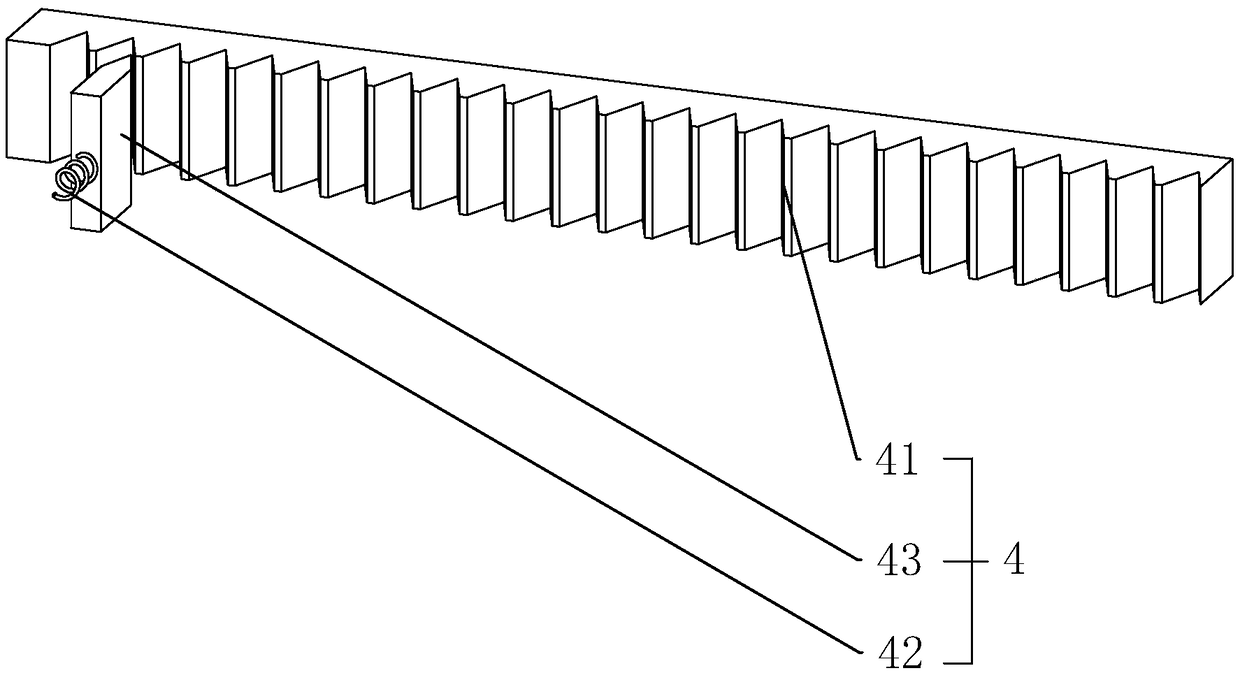

[0027] A guide assembly 3 for guiding the support plate 2 is arranged between the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com