Subway tunnel segment reinforcing cage overturning machine and overturning method

A technology of subway segments and steel cages, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of potential safety hazards, large repairs, and large demand for subway segments, and achieve the goals of avoiding rework and high turnover efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

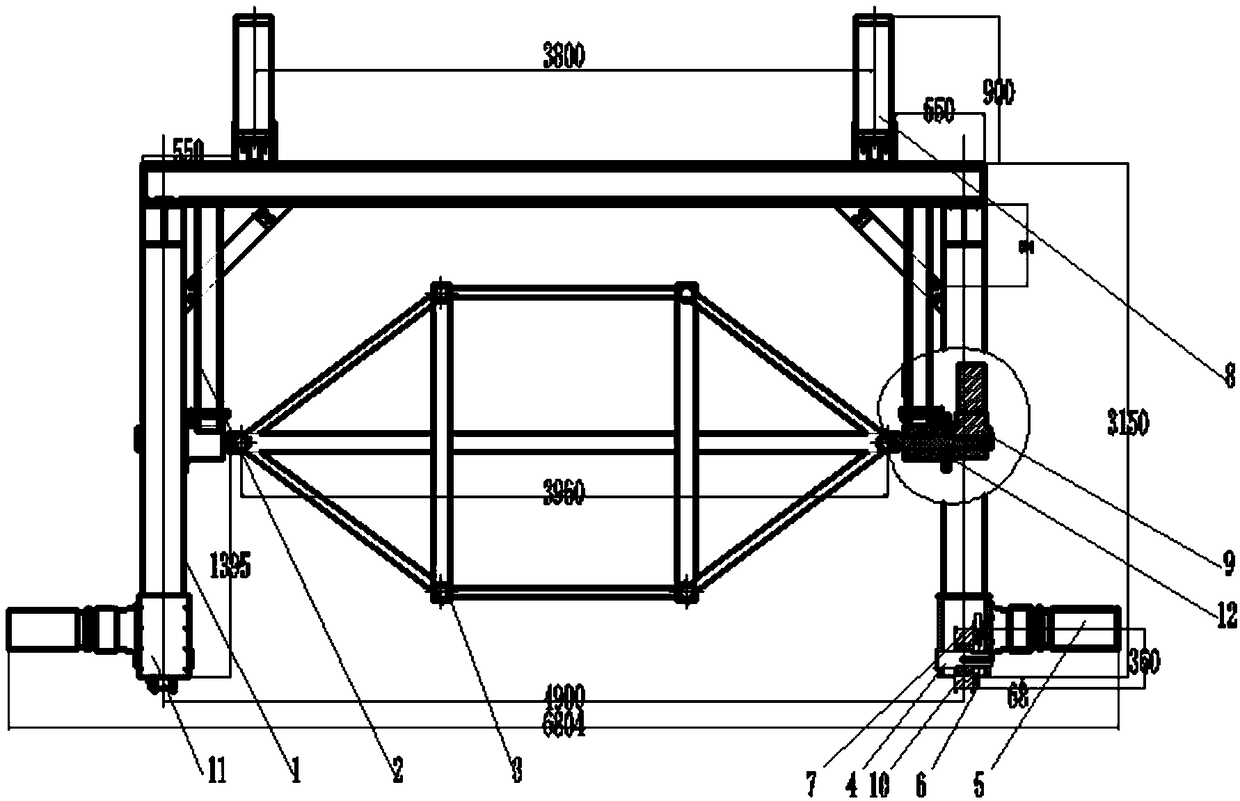

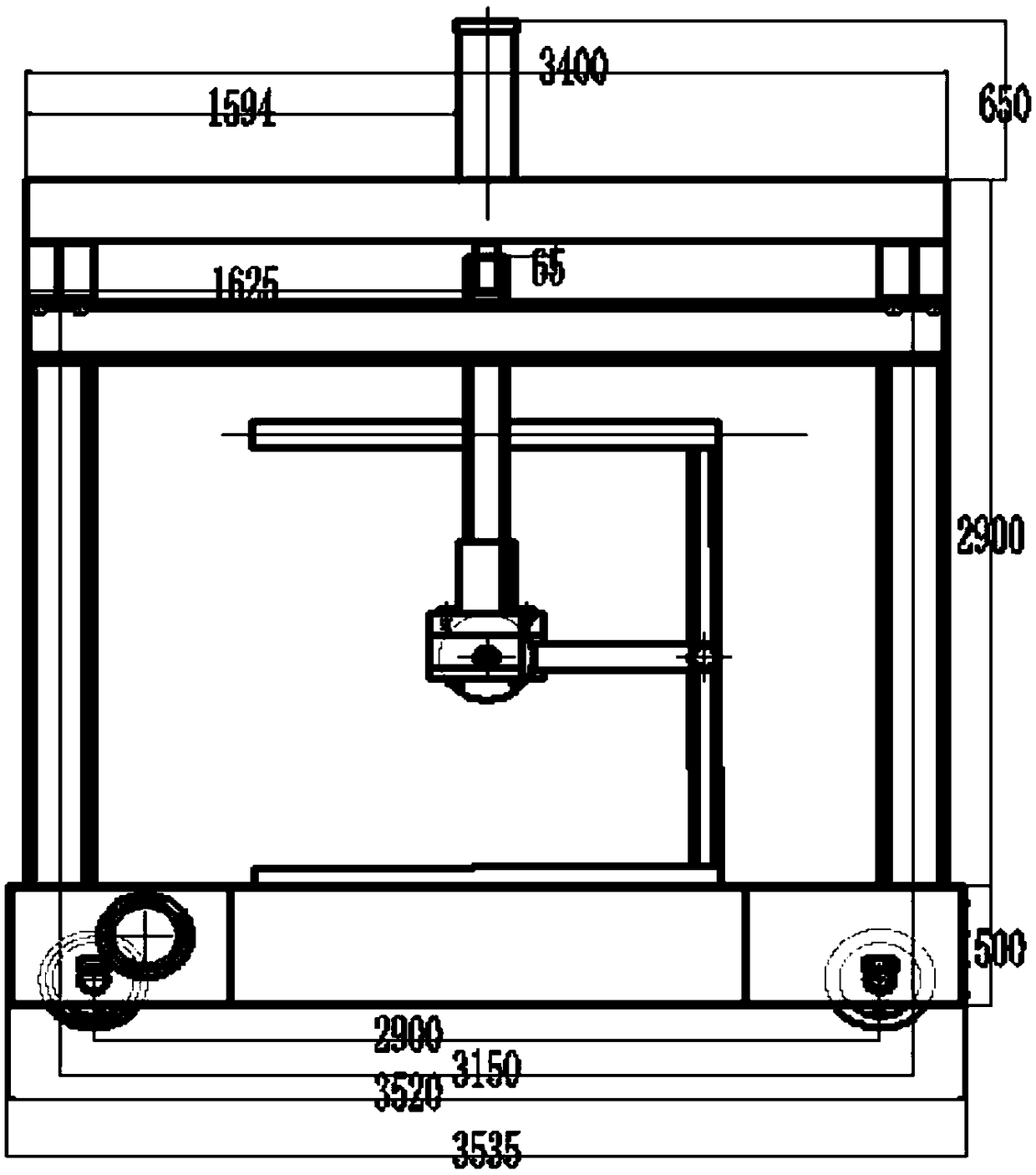

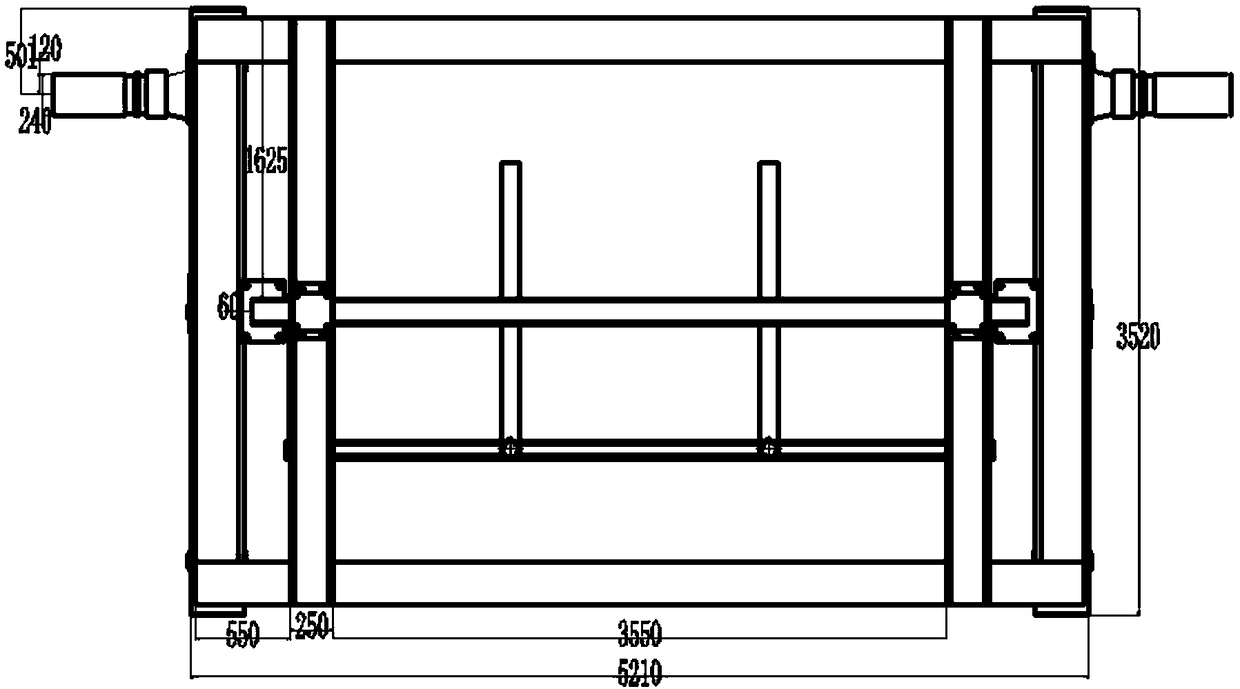

[0026] Such as Figure 1-Figure 3 As shown, the subway segment steel cage turning machine includes a running unit, a lifting unit and a rotating unit, and the running unit, lifting unit and rotating unit are all installed on the frame 1;

[0027] The running unit includes the first motor 5 and the wheel 10 driven by the first motor 5. The driving gear is installed on the rotating shaft of the first motor 5. The driven gear 6 is fixed on the side of the wheel 10. The driving gear and the driven gear 6 are used in conjunction; the wheel 10 is installed At the bottom of frame 1;

[0028] The lifting unit includes a cylinder 8 and a lifting frame arranged on the top of the vehicle frame 1, the lifting frame is fixed with the telescopic rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com