Detecting system and method for spin locks of containers

A detection system and container technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of harsh and complex port working environment, yard collapse, high labor intensity, etc., to improve operation efficiency, prevent accidents, universal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

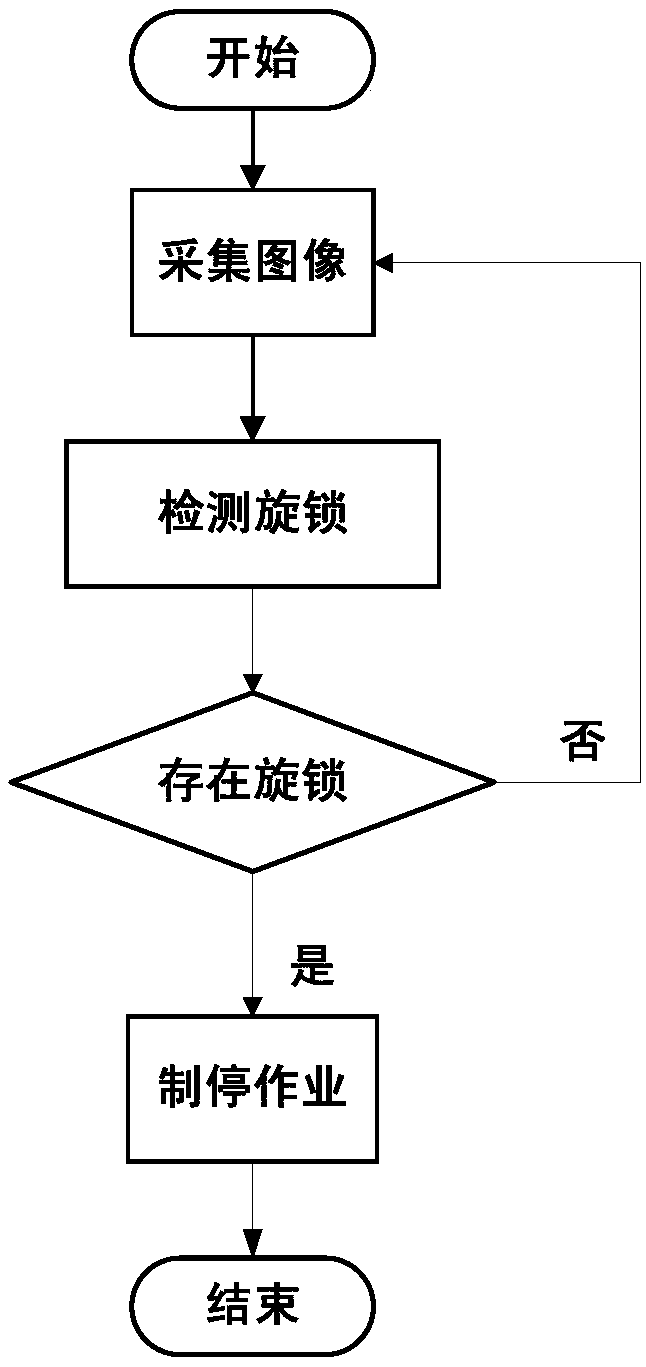

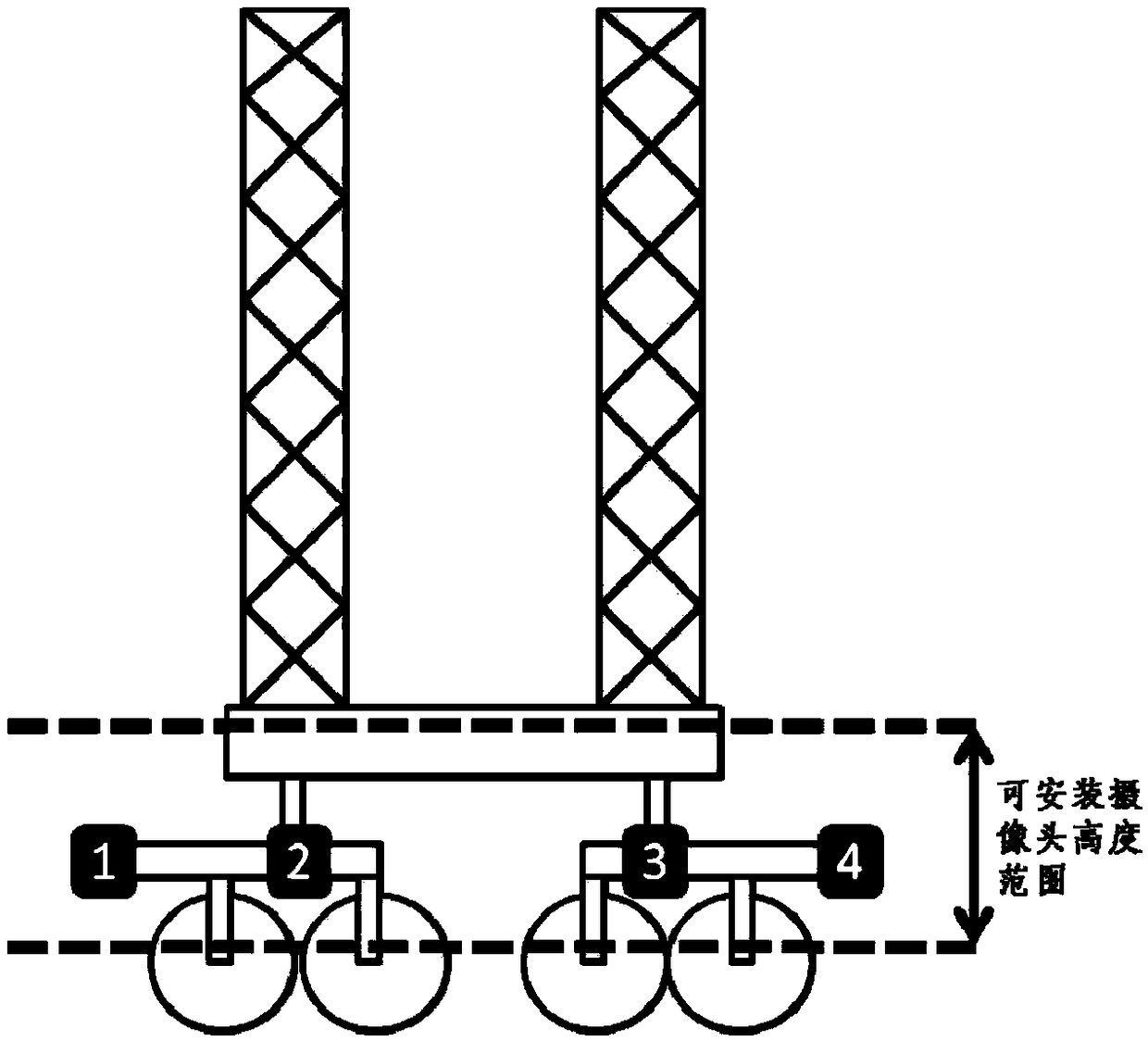

[0050] Step 1: Install 2-channel cameras (total 4-channel) on the columns beside the dragon legs at the front and rear ends of the gantry crane, and mark them as 1, 2, 3, 4, and No. 1, 2, 3, and 4 at a time from the front end to the parking space, and use them to obtain containers of different sizes Image information for frontend and backend. Preferably, the inner and outer corners of the same end (front end or rear end) of the same container always appear in the same camera at the same time without being blocked. Among them, the installation position of the camera is as follows: figure 2 shown.

[0051] Step 2: When it is used for the first time or needs to be re-calibrated, use a 4-way camera to collect a series of image data of abnormal working conditions in which the twistlocks have not been completely removed during container loading and unloading to form a sample image database. Preferably, the twistlocks that have not been removed should include various models as muc...

Embodiment 2

[0059] Step 1: Install 3 cameras (6 cameras in total) on the columns next to the dragon legs at the front and rear ends of the gantry crane, respectively, to obtain image information of the front and rear ends of containers of different sizes. Preferably, the inner and outer corners of the same end (front end or rear end) of the same size container always appear in the same camera at the same time without being blocked.

[0060] Step 2: Use the four-way camera installed in step 1 to collect image data of a series of abnormal working conditions in which the twistlocks are not completely removed during container loading and unloading. Preferably, the twistlocks that have not been removed should include various models as much as possible, and the working environment should cover all kinds of weather, such as rainy days and foggy days.

[0061] Extract the feature information of the spinlock in each frame sample image.

[0062] The above feature information is counted and a model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com