Multi-layer high-strength thermal-insulation material and preparation method thereof

A heat insulation and high-strength technology, applied in ceramic products, other household appliances, applications, etc., can solve problems that affect the use effect and life, performance degradation, hazards, etc., to achieve suitable for large-scale industrial production, stable product quality, The effect of strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

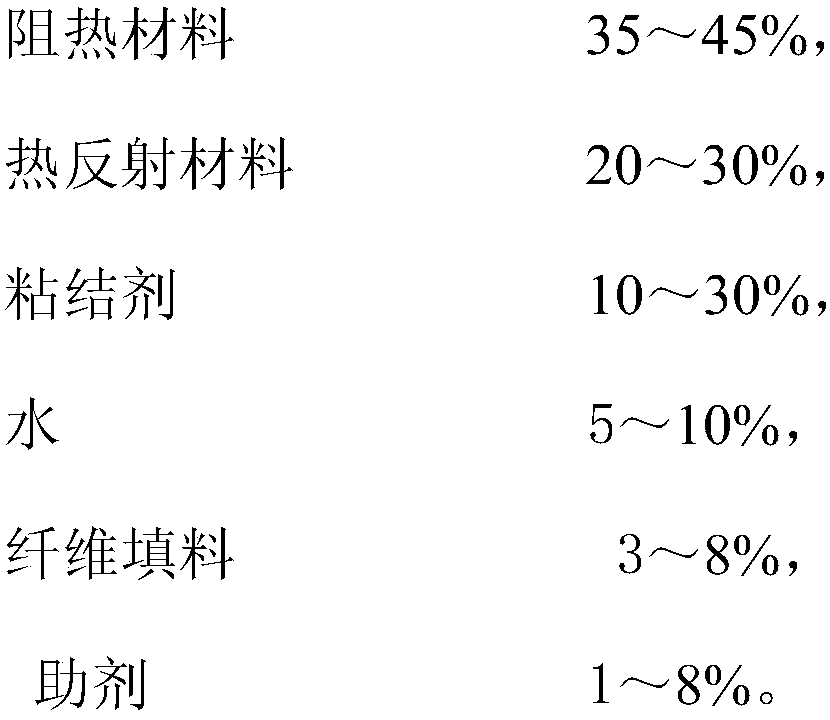

Method used

Image

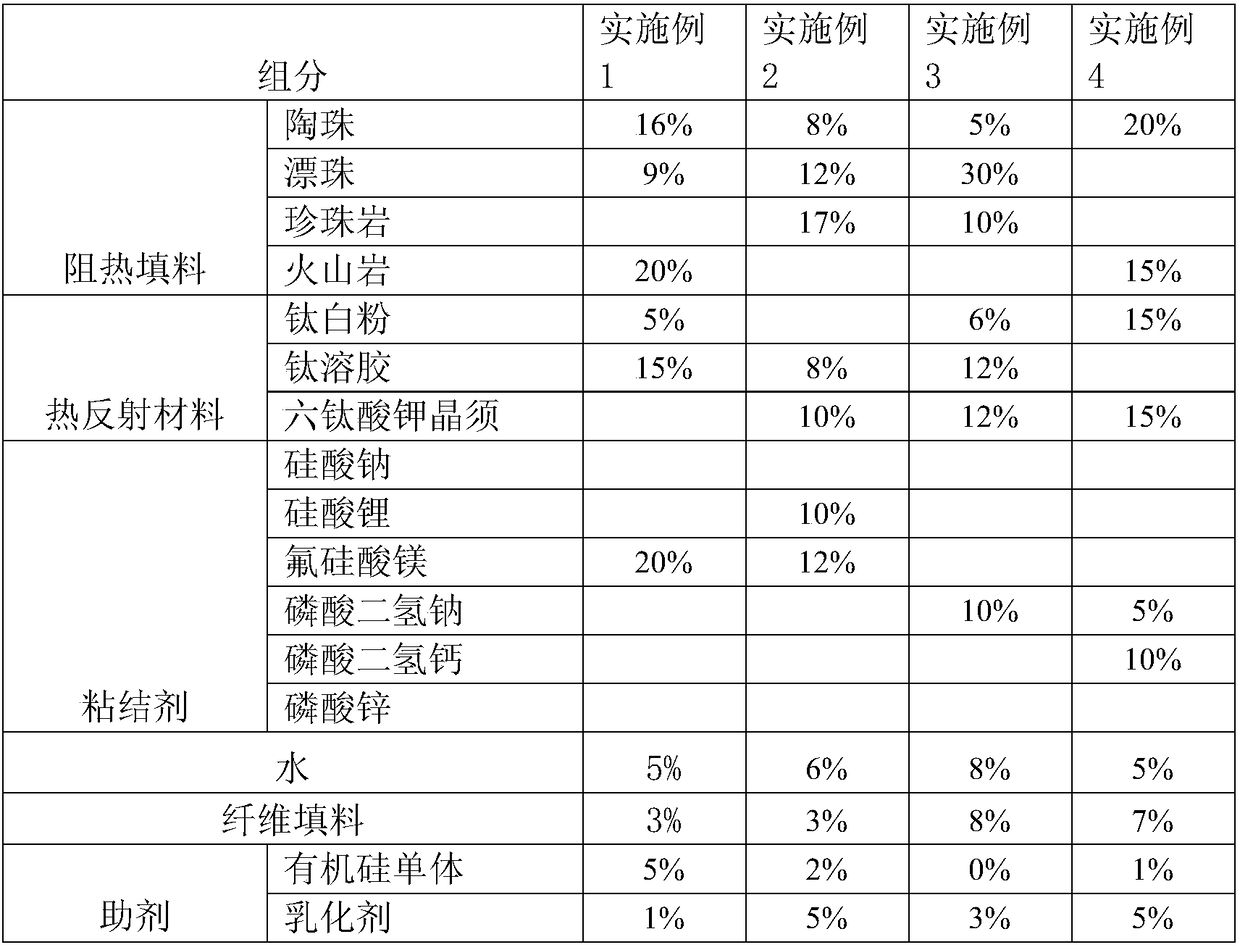

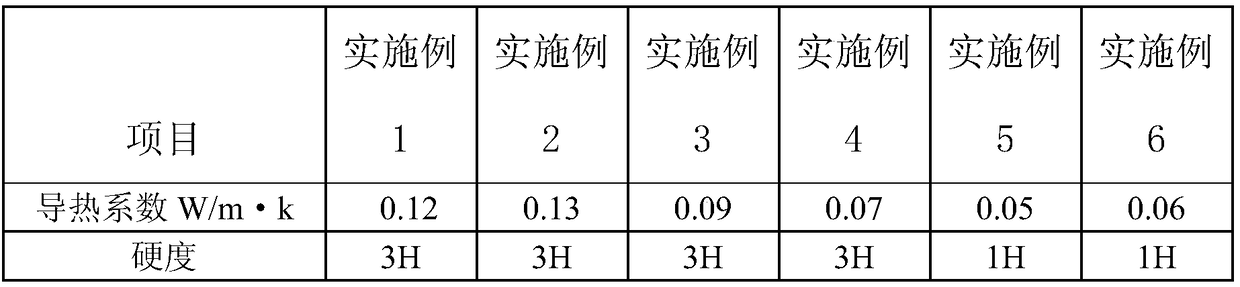

Examples

Embodiment 1~4

[0022] A method for preparing a multi-layer high-strength thermal insulation material, comprising the steps of:

[0023] 1), preferably, the preparation method of the airgel core material is as follows: the glass fiber filaments are chopped to a length of 5-10 mm, and then fluffed, combed together with a leavening agent into monofilaments, and knotted in a mould. Form a felt net, then laminate the felt net, control the thickness within 1mm, insert the trachea into the gap between the felt nets, then seal the mold into a vacuum bag, and start to inject silica airgel along the trachea after vacuuming for about 15 seconds , and then connect the mold into the oven, bake at 135-165°C for 10-12 minutes, and obtain the airgel core material after cooling;

[0024] 2) Put the airgel core material into the mold, and pull it with the wire to keep the same distance from the two side walls of the mold;

[0025] 3) The structural support layer material composed of heat-resistant material, ...

Embodiment 5~6

[0028] A method for preparing a multi-layer high-strength thermal insulation material, comprising the steps of:

[0029] 1), preferably, the preparation method of the airgel core material is as follows: the glass fiber filaments are chopped to a length of 5-10 mm, and then fluffed, combed together with a leavening agent into monofilaments, and knotted in a mould. Form a felt net, then laminate the felt net, control the thickness within 1mm, insert the trachea into the gap between the felt nets, then seal the mold into a vacuum bag, and start to inject silica airgel along the trachea after vacuuming for about 15 seconds , and then connect the mold into the oven, bake at 135-165°C for 10-12 minutes, and obtain the airgel core material after cooling;

[0030] 2) Put the airgel core material into the mold, and pull it with the wire to keep the same distance from the two side walls of the mold;

[0031] 3) The structural support layer material composed of vinyl silicone resin, cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com