A kind of preparation method of matting ultra-high molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon filament, fiber chemical characteristics, rayon manufacturing, etc. The effect of preserving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

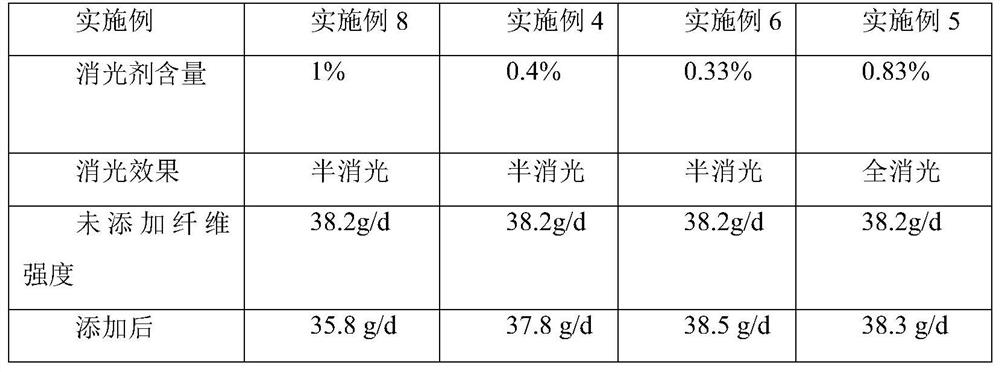

Examples

Embodiment 1

[0031] Embodiment 1 A kind of preparation method of matting mother liquor for ultra-high molecular weight polyethylene fiber

[0032] Step 1) Grind and mix 40 g of native nano-titanium dioxide, 1.8 g of sodium lauryl sulfate, 0.5 g of polyvinyl alcohol and 57.7 g of white mineral oil to obtain a high-concentration matting mother liquor, wherein the largest concentration of the native nano-matting agent is The particle diameter is less than 2 microns, and the average particle size is less than 0.5 microns;

[0033] Step 2) Add 48.9g of white mineral oil, 0.5g of sodium lauryl sulfate, 0.6g of Natrosol AT250 and 50g of the high-concentration matting mother liquor obtained in step 1) into high-speed shearing equipment for high-speed shearing to obtain ultra-high molecular weight polyethylene Fiber matting master solution.

[0034] Calculated by mass percentage, the matting mother liquor is composed of 20% matting agent, 78.2% solvent, 1.2% surfactant, 0.25% dispersant, 0.3% thicke...

Embodiment 2

[0035] Embodiment 2 A kind of preparation method of matting mother liquor for ultra-high molecular weight polyethylene fiber

[0036] Step 1) Grind and mix 42g of native nano-silica agent, 2g of nonylphenol polyoxyethylene (10) ether-2-sulfosuccinic acid monoester disodium salt, 0.5g of EFKA4560 and 55.5g of white mineral oil , to obtain high-concentration matting mother liquor;

[0037] Step 2) 61 g of white mineral oil, 1 g of nonylphenol polyoxyethylene (10) ether-2-sulfosuccinic acid monoester disodium salt, 0.6 g of Natrosol AT250 and 37.4 g of the high-concentration matting mother liquor obtained in step 1) Add high-speed shearing equipment for high-speed shearing to obtain a matting mother liquor for ultra-high molecular weight polyethylene fibers.

[0038] Calculated by mass percentage, the matting mother liquor is composed of 25% matting agent, 72.5% solvent, 1.5% surfactant, 0.2% dispersant, 0.4% thickener and the balance of auxiliary agents.

Embodiment 3

[0039] Embodiment 3 A kind of preparation method of full-dull ultra-high molecular weight polyethylene fiber

[0040] 8g of ultra-high molecular weight polyethylene, 92g of white mineral oil and 0.32g of the extinction mother liquor prepared by the method of Example 1 were injected into the batching kettle; while stirring, they were fed into a twin-screw extruder for extrusion spinning, and then extracted, dried and Multi-stage drawing, so as to prepare a full-dull ultra-high molecular weight polyethylene fiber with a content of 0.8% of a matting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com