Baffle plate and shell-and-tube heat exchanger

A shell-and-tube heat exchanger and baffle technology, which can be applied to heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of large flow resistance, development restrictions, and low heat transfer efficiency. To achieve the effect of enhancing the degree of turbulence, avoiding the flow dead zone, and enhancing the heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the embodiment is only an illustration of the gist of the present invention, rather than limiting the protection scope of the present invention.

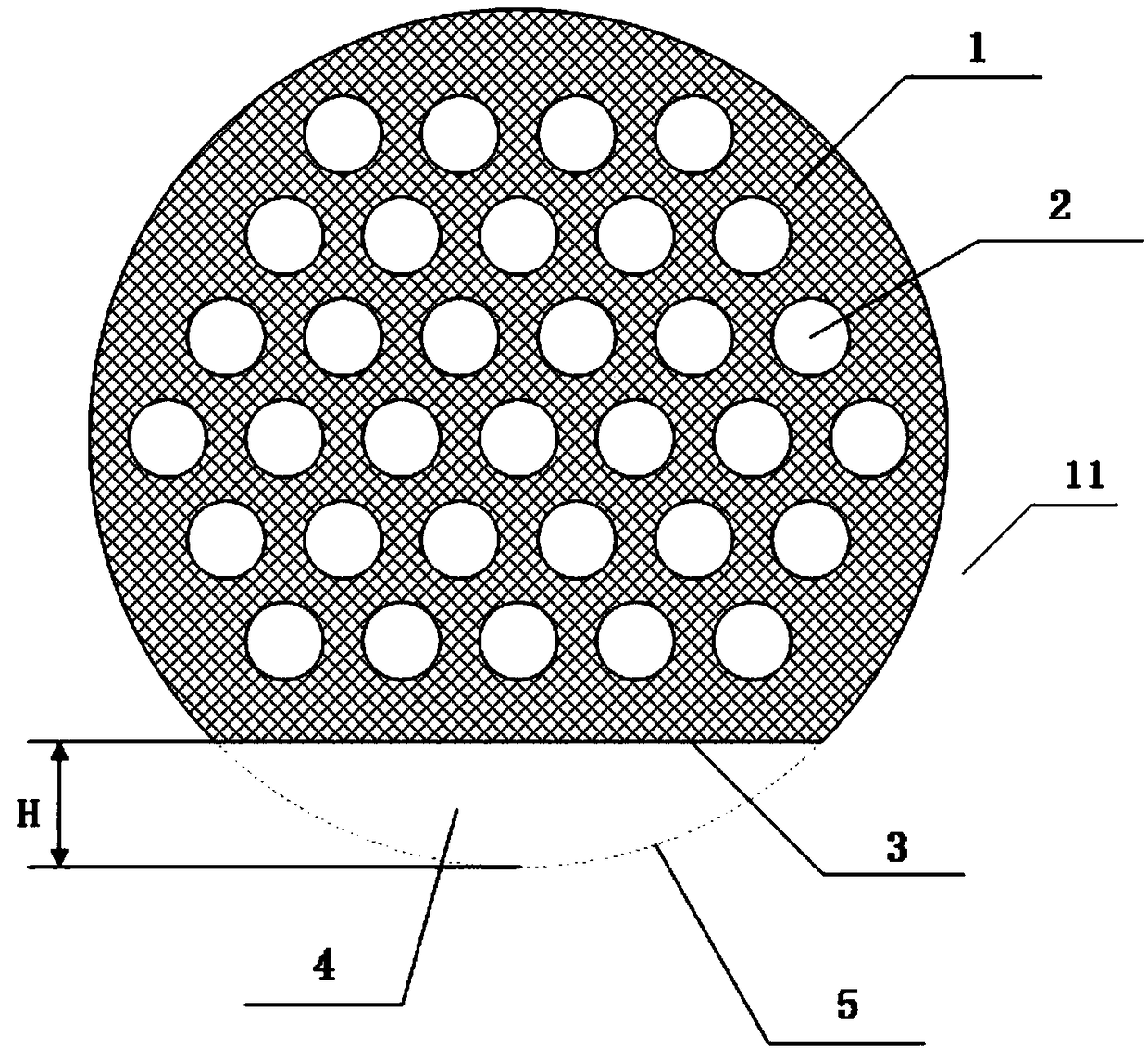

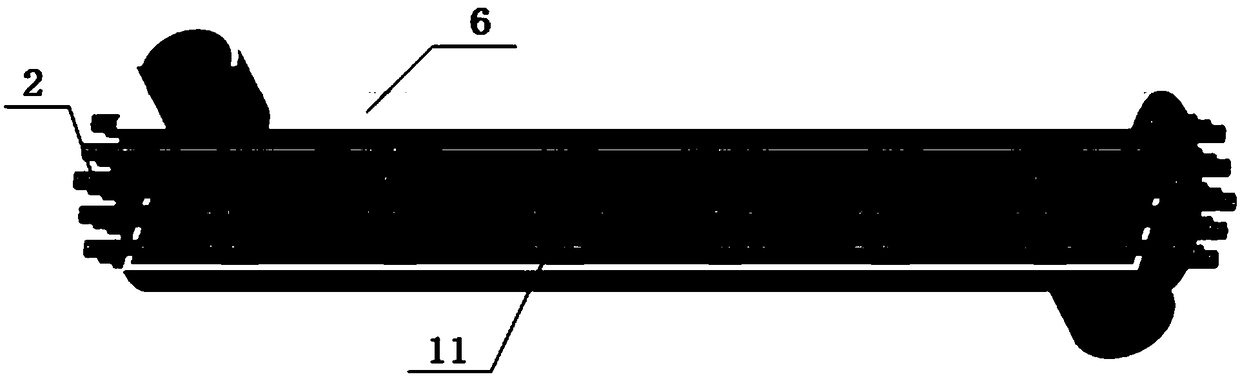

[0022] Such as figure 1 As shown, a baffle plate 11 provided by the present invention includes a body 1 provided with a tube hole 2, which is installed in a cylindrical shell of a heat exchanger, wherein one side of the edge surface of the body is a mounting surface, so The mounting surface is attached to the inner wall of the housing, and the other side of the edge surface of the body is a circulation notch surface 3, and the circulation notch surface and the inner wall 5 of the housing form a circulation notch 4 for the medium to pass through. The body is made of foam metal material.

[0023] The baffle of the present invention is made of foam metal material. Compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com