A method for estimating reliability parameters of electromechanical components

A reliable, electromechanical technology, applied in the direction of electrical digital data processing, calculation, special data processing applications, etc., can solve the problems of not being able to accurately know the time of product failure, and not being able to obtain the numerical information of the life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] In an embodiment, the [FT] type reliability data of a certain electromechanical part is shown in the following table. It is known from engineering experience that the life of the electromechanical part obeys the Weibull distribution. Try to estimate the scale parameters and shape parameters of the life distribution.

[0060]

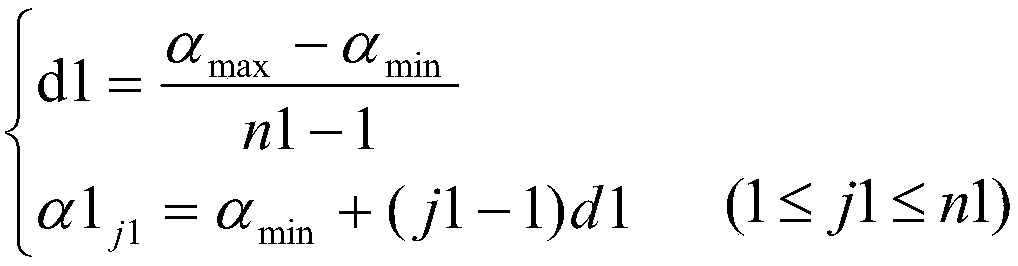

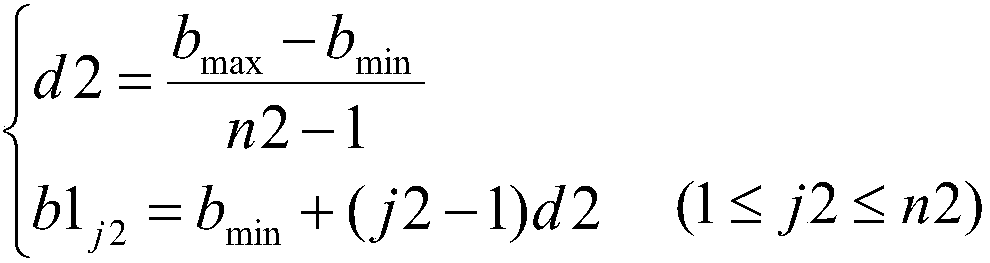

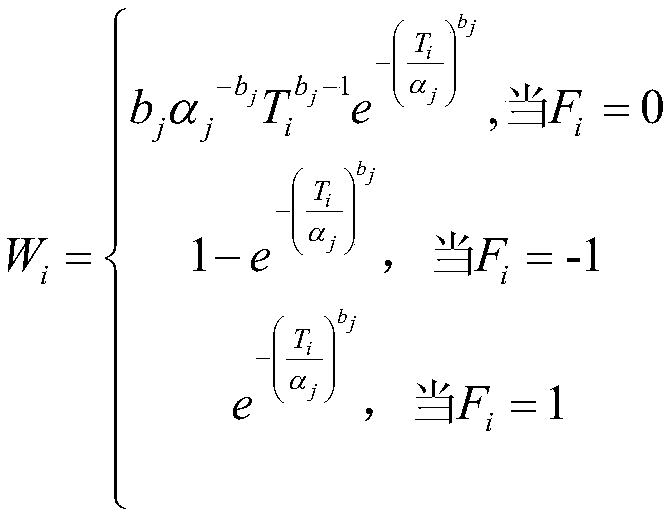

[0061] According to previous experience, the scale parameter of the life distribution of the electromechanical part is in the range of 500-3000, with a step size of 500; the shape parameter is in the range of 1.1-3.8, with a step size of 0.3, and a total of 60 candidate distribution parameters are generated. (α j ,b j ),1≤j≤60, the calculation results are shown in the table below:

[0062]

[0063]

[0064] It can be seen from the table that in L j The maximum value in (1≤j≤64) is L 35 , then α 35 =2000, b 35 =2.3 is the estimated value of the life distribution parameter of the electromechanical part.

[0065] For further verifying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com