Flexible organic light-emitting display and spring assembly

一种发光显示器、弹簧组件的技术,应用在有机半导体器件、由几个弹簧组成的弹簧组件、弹簧等方向,能够解决膜层变形不能协调、相互作用增加膜材应力水平、再展开无法保持平整等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Apparently, the described embodiments are only some of the embodiments of this application, not all of them. Based on the embodiments in this application, all other embodiments obtained by those skilled in the art without making creative efforts belong to the scope of protection of this application.

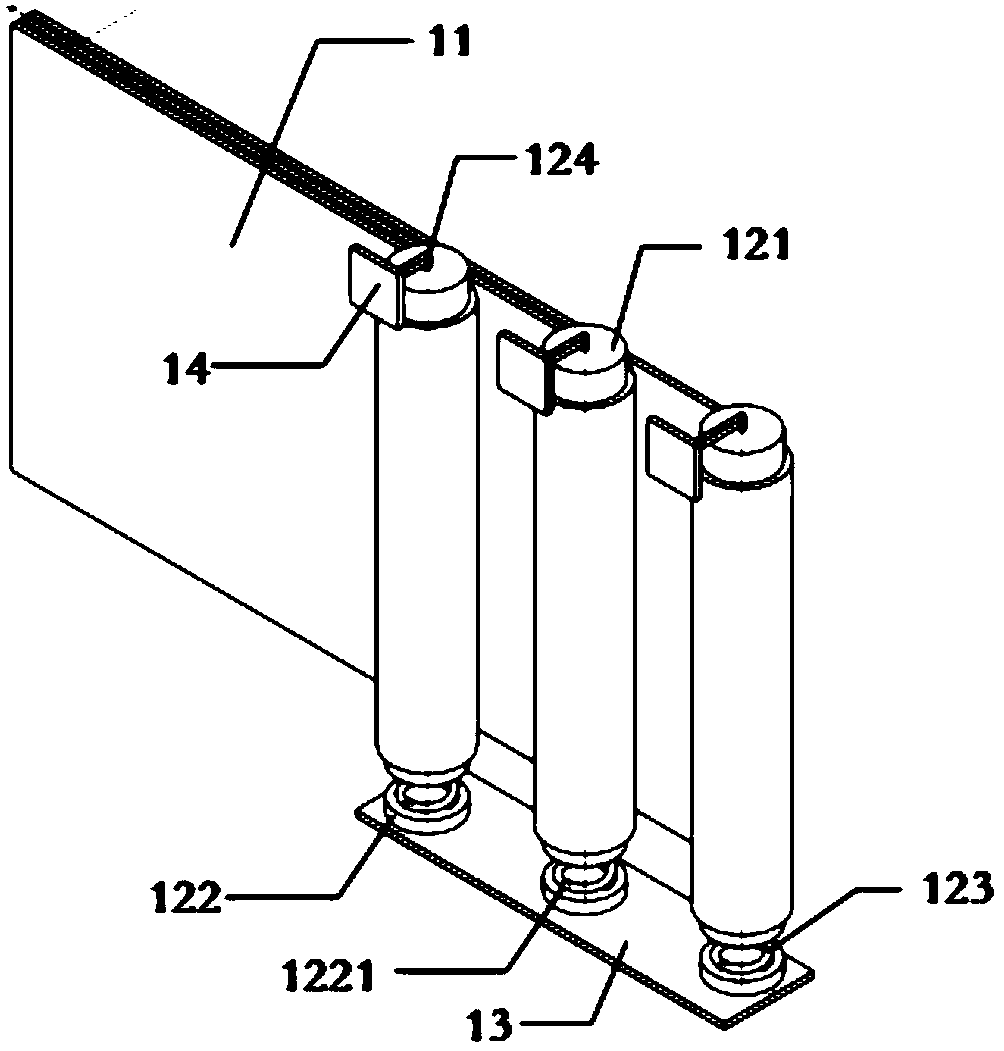

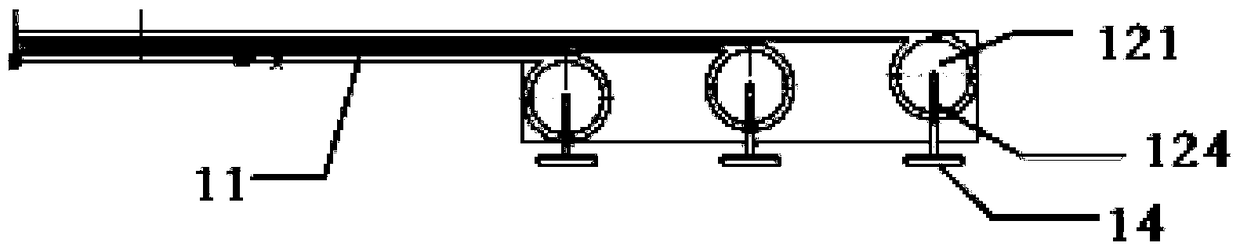

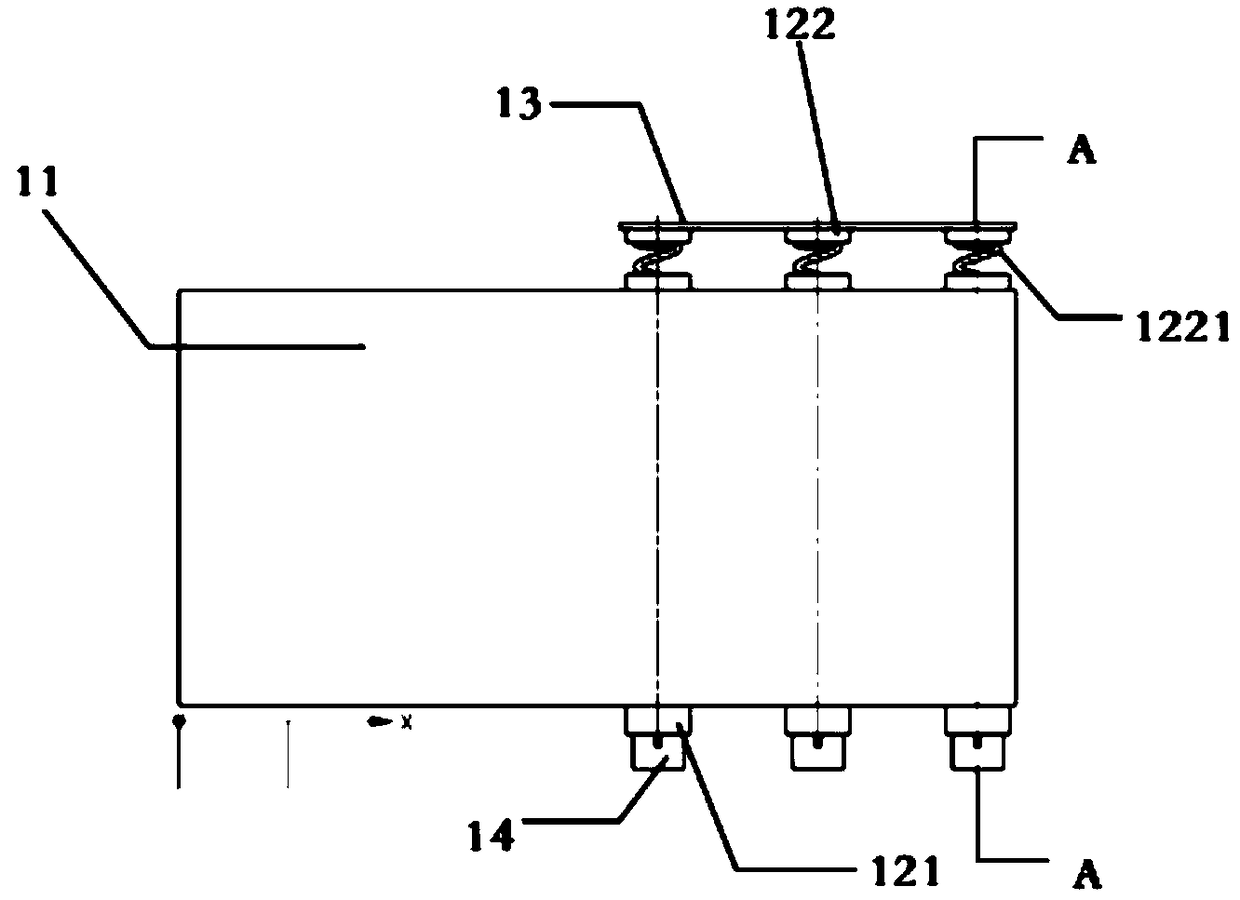

[0035] see figure 1 , figure 2 as well as image 3 , which is a schematic diagram of a flexible organic light emitting display according to the first embodiment of the present application. The flexible organic light emitting display includes a display panel, and the display panel includes:

[0036] At least two layers of film layers 11, one end of one film layer 11 is fixed to one end of another adjacent film layer 11;

[0037] A lubricating layer (not shown) between two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com