High-speed disc type permanent magnet speed regulating device

A permanent magnet speed regulation, disc technology, applied in the direction of electromechanical devices, permanent magnet clutches/brakes, casings/covers/supports, etc., can solve the problem of increasing equipment wear and temperature, reducing equipment service life, axial The movement requirements are very strict, so as to ensure the normal operation, improve the service life, and achieve the effect of good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

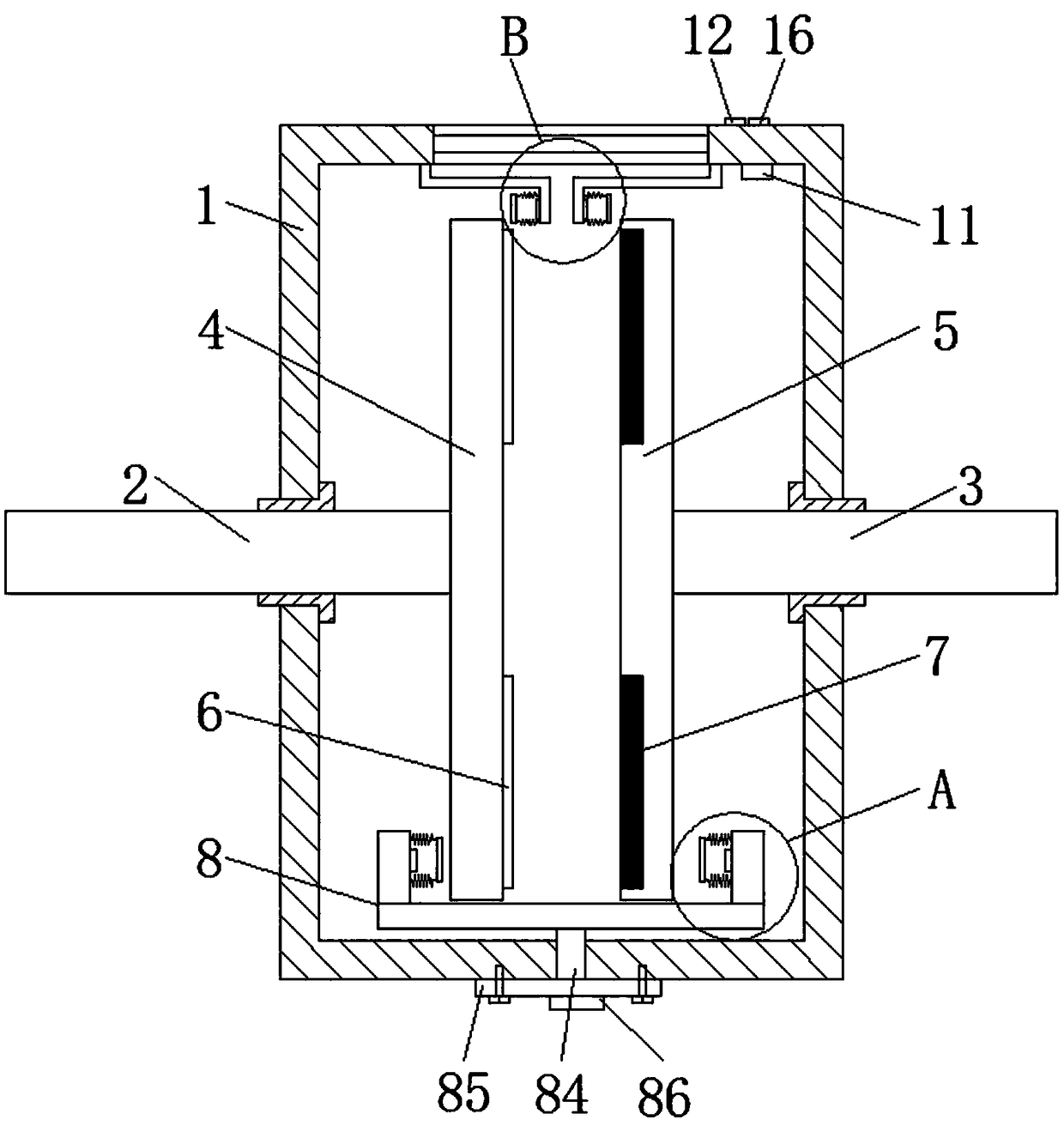

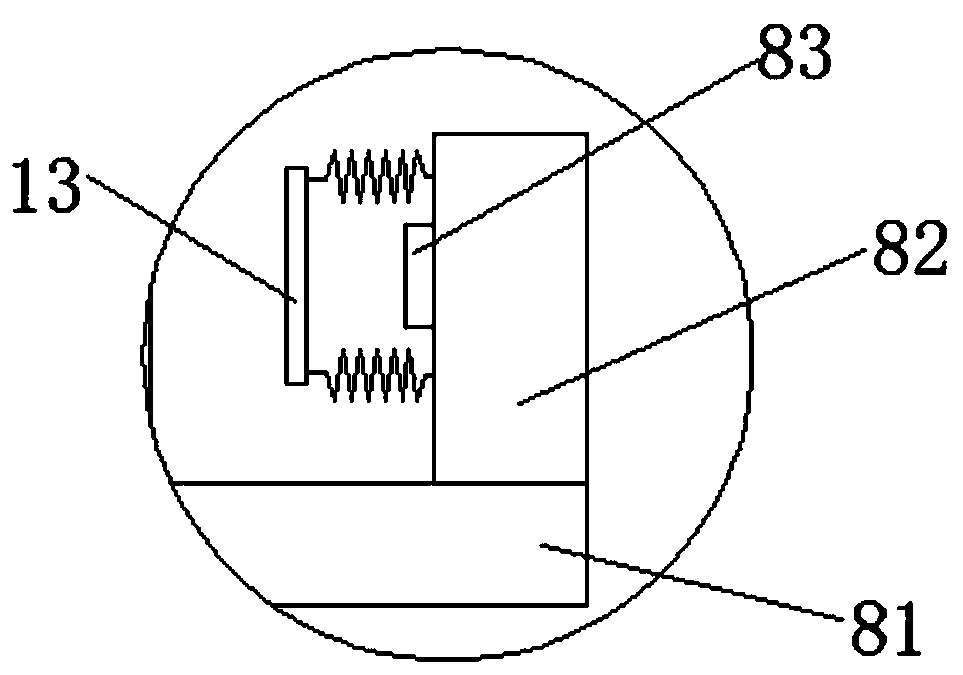

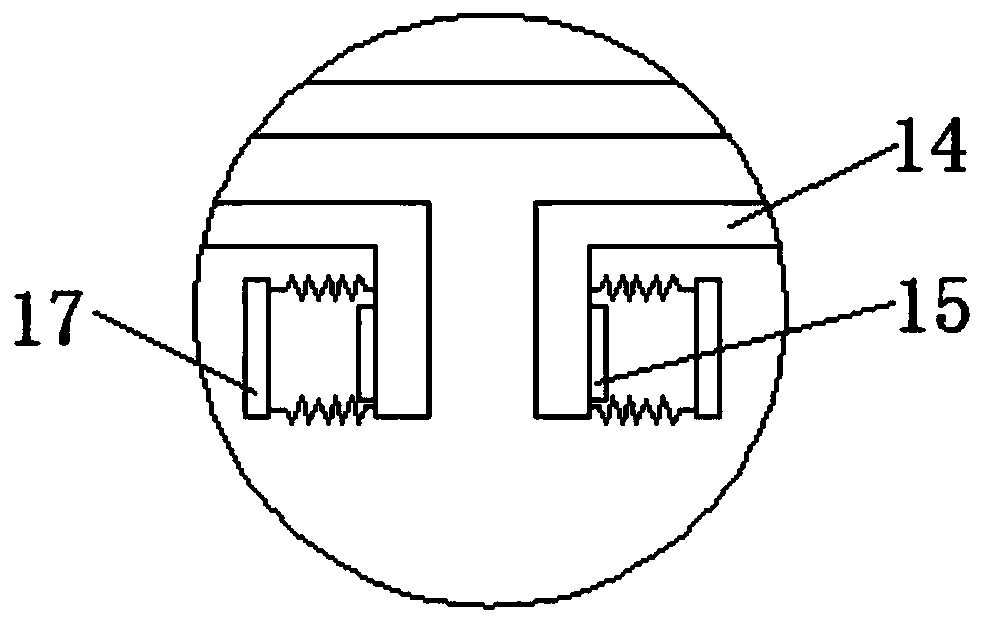

[0023] refer to Figure 1-4 , a high-speed disc-type permanent magnet speed control device, including a housing 1, one end of the housing 1 is connected to an input shaft 2 through a bearing, an output shaft 3 is provided at the end of the housing 1 away from the input shaft 2, and the input shaft 2 and The axes of the output shaft 3 are collinear, and the input shaft 2 and the output shaft 3 are respectively equipped with a conductor disk 4 and a magnet disk 5. The conductor disk 4 is provided with a conductor ring 6 near the end of the magnet disk 5, and the magnet disk 5 is close to the conductor disk 4. One side is embedded with a permanent magnet block 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com