Wheel brow installing assembly used for vehicle and vehicle

A technology for installing components and wheel eyebrows, which is applied in vehicle parts, transportation and packaging, superstructure and other directions, can solve the problems of easy buckle failure and high maintenance costs of wheel eyebrows, and achieves reduction of processing cost and processing difficulty, simple structure, and low cost. The effect of demolding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

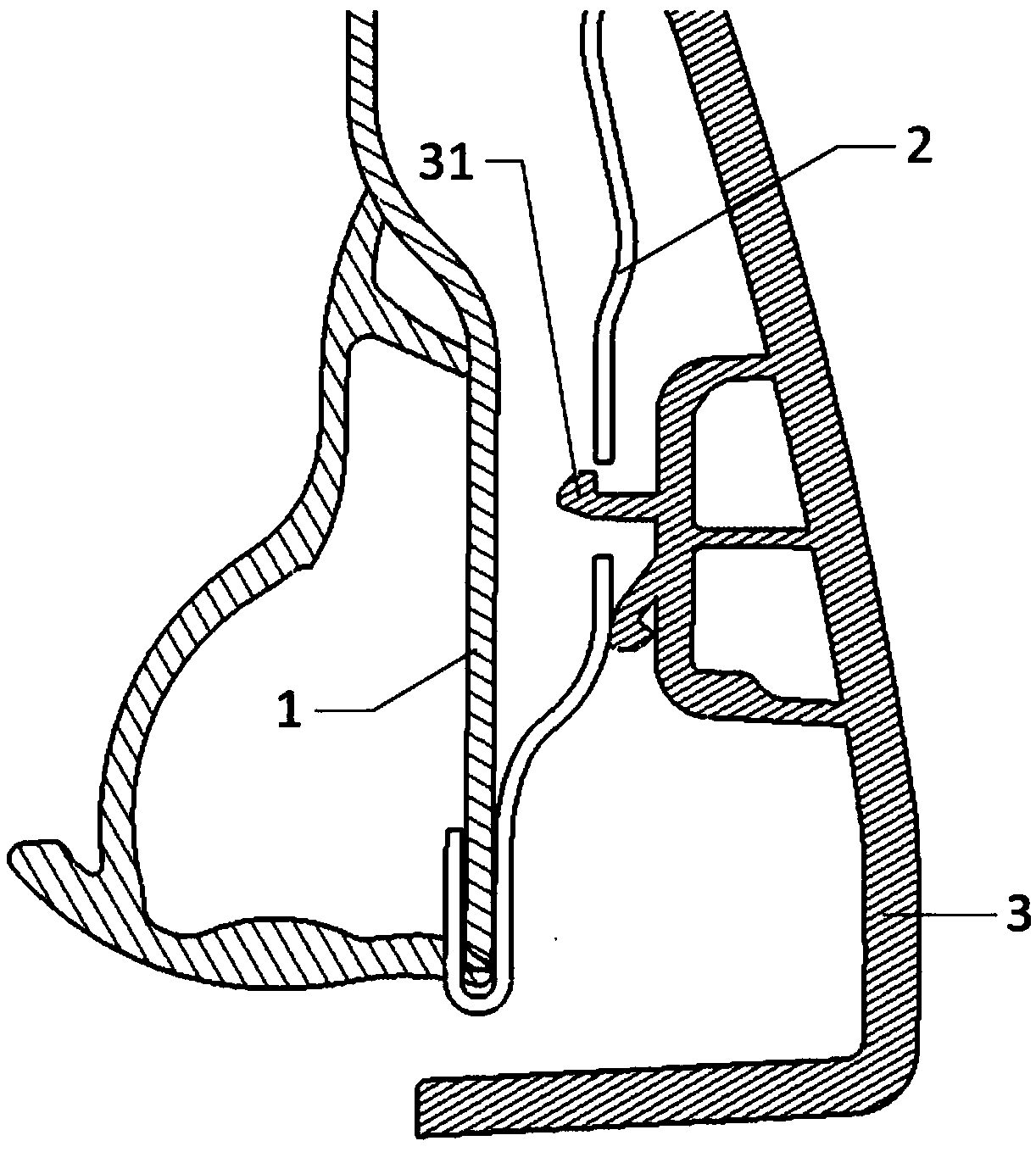

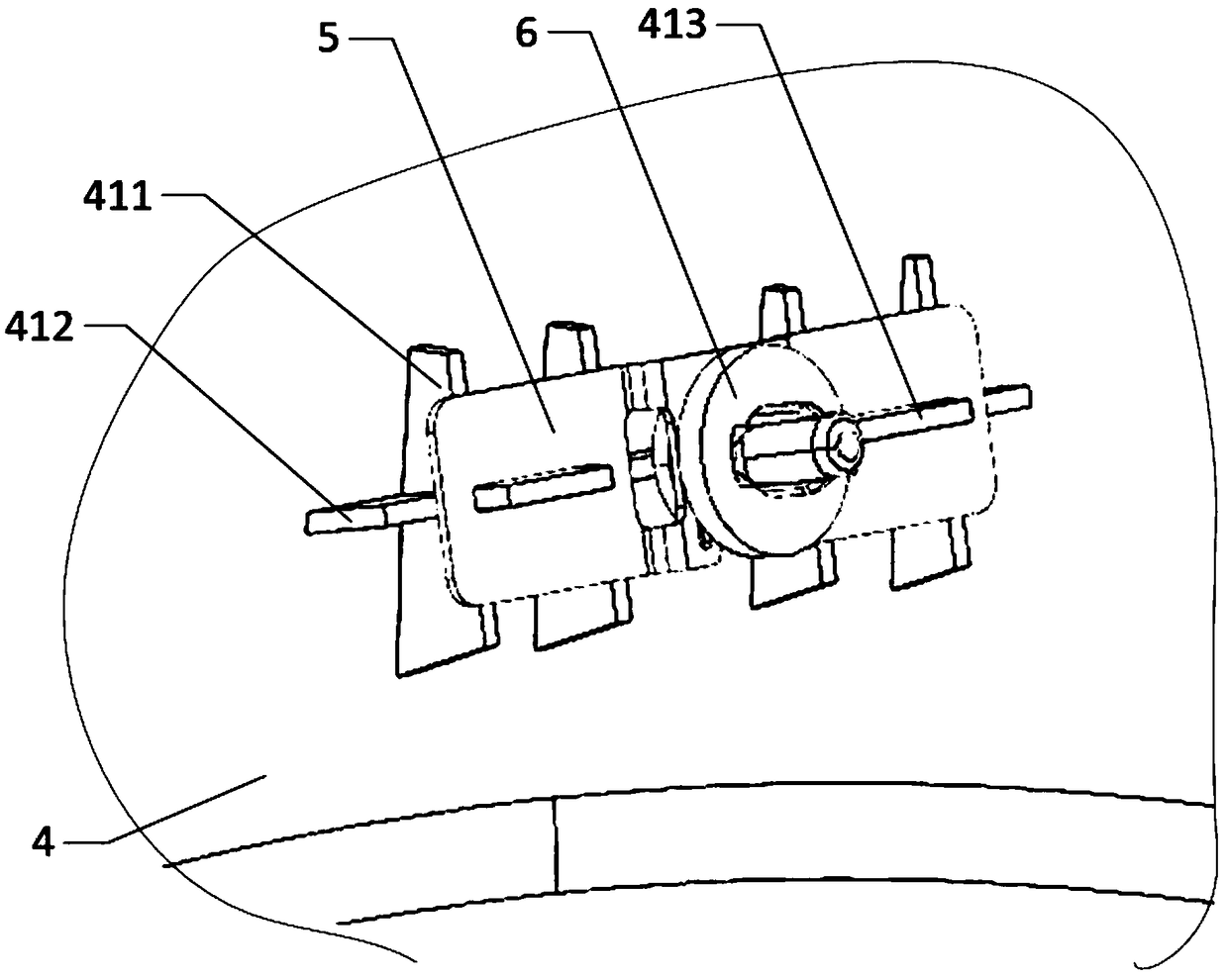

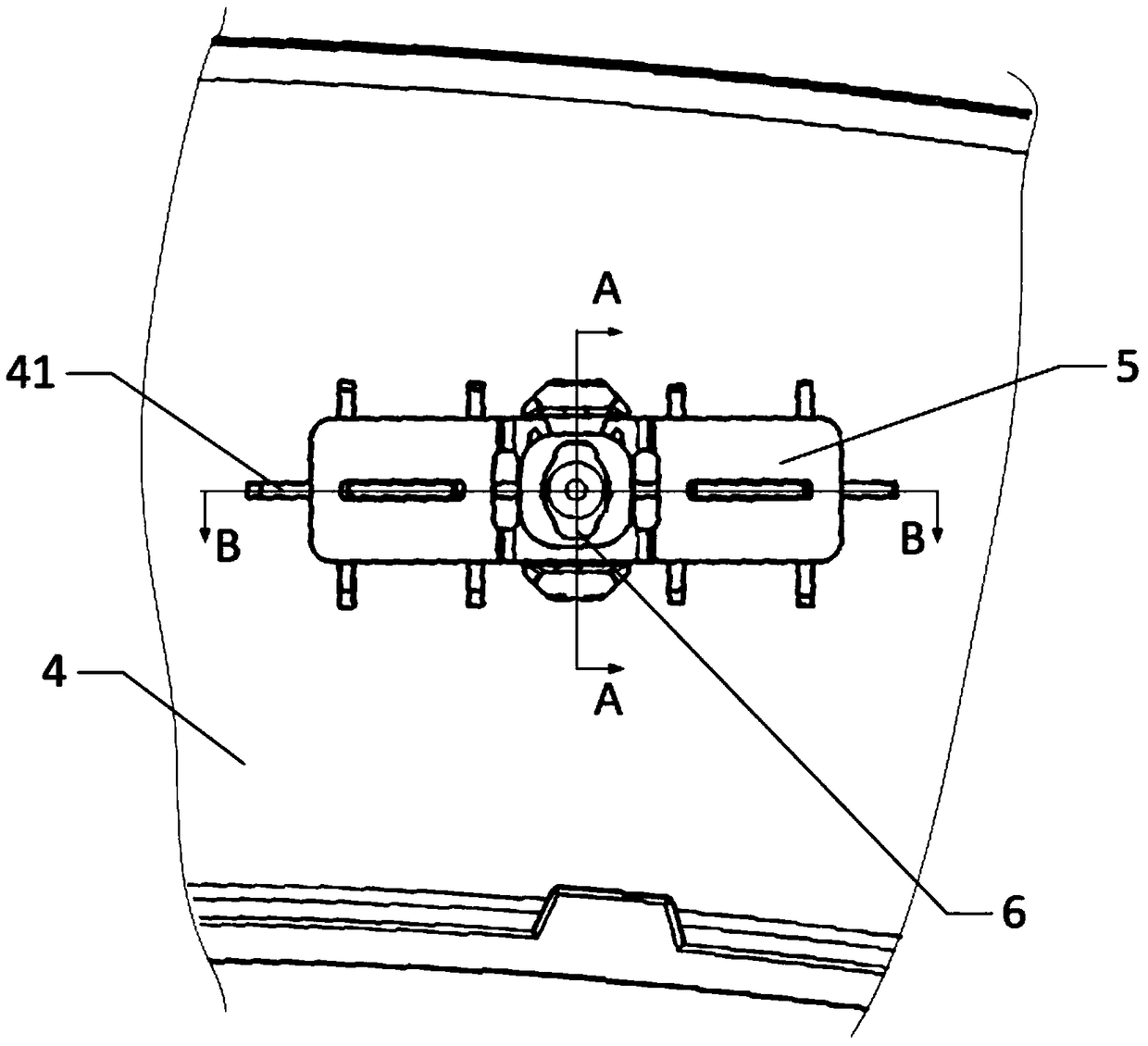

[0064] refer to Figure 2-Figure 7 , the wheel arch installation assembly in this embodiment includes:

[0065] The support seat 41 is arranged on the inner surface of the wheel eyebrow body 4 .

[0066] The connecting member 5 is fixedly installed on the support base 41 , and a buckle mounting position (not shown) is formed on the connecting member 5 .

[0067] Buckle, which includes an integrally formed clamping part (not marked) and a fixed part (not marked), the fixed part can be fixedly installed on the buckle installation position, and the clamping part can be clamped into the sheet metal hole of the sheet metal part , in order to securely connect the wheel arch to the sheet metal part.

[0068] Specifically, refer to Figure 4 , The support base 41 includes a plurality of transverse and / or longitudinal ribs. The support seat 41 in this embodiment includes 4 longitudinal ribs 411 arranged at intervals, and a transverse rib 412 arranged transversely for connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com