Hydrofoil seaplane

A hydroplane and hydrofoil technology, applied in the field of hydroplanes and hydrofoils, can solve the problems of engine power mismatch, reduce aircraft payload, and heavy power system weight, reduce immersion area, fast and flexible water surface movement ability, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

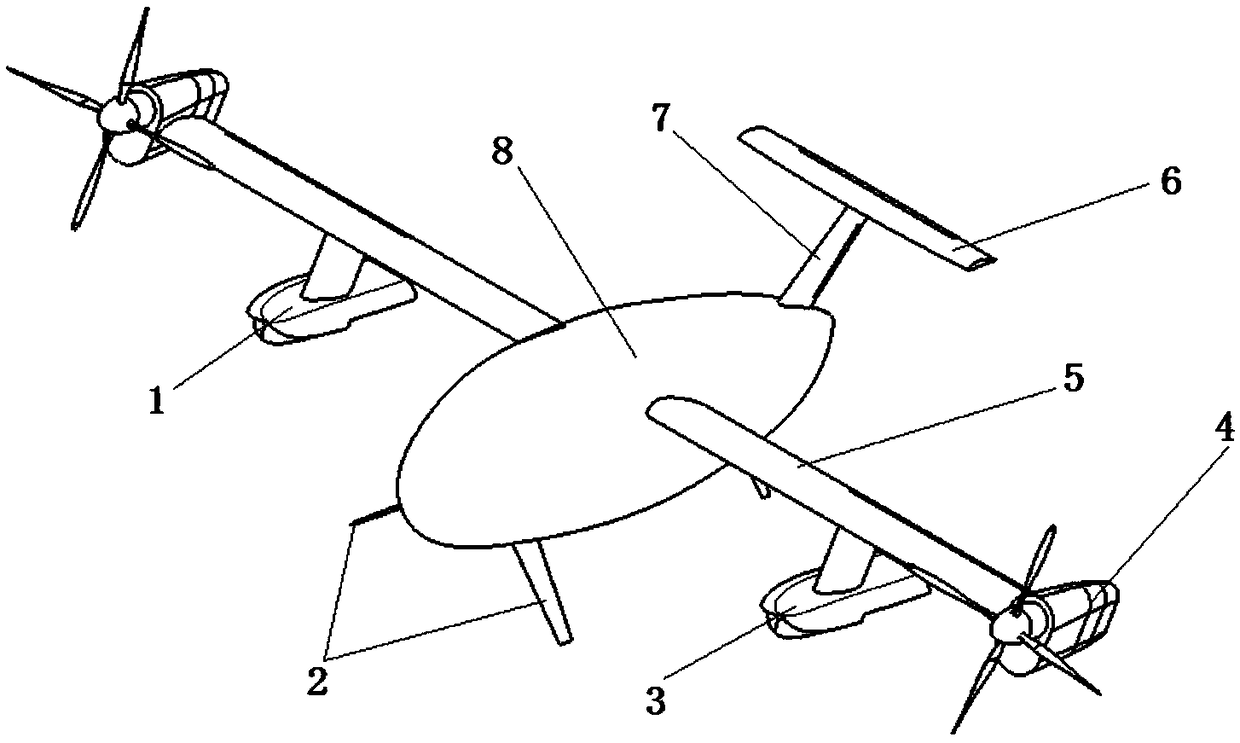

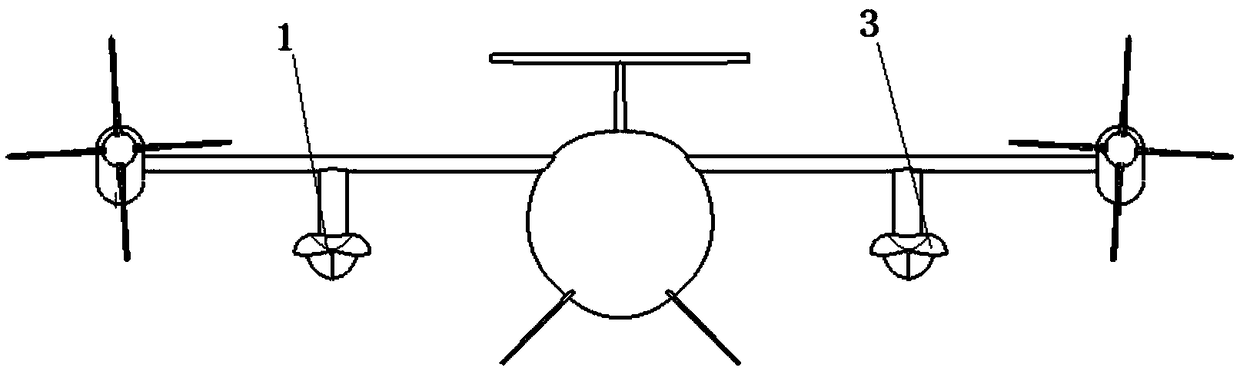

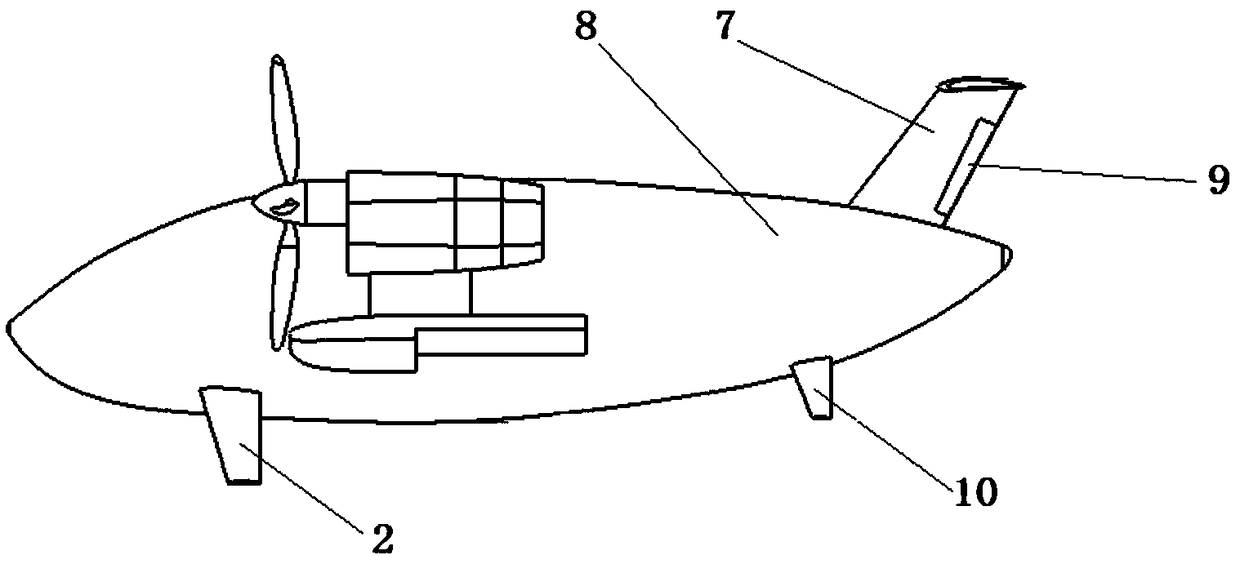

[0023] Such as Figure 1~4 As shown, the hydrofoil type seaplane of the present invention is provided with a hydrofoil device at the lower end of the fuselage 8, and the hydrofoil device is mainly composed of a front hydrofoil 2 and a rear hydrofoil 10, and the front hydrofoil 2 is installed on the front of the fuselage 8 lower end. The rear hydrofoil 10 is installed on the tail of the fuselage 8 lower end. Both the front hydrofoil 2 and the rear hydrofoil 10 use the SIMPLE7 airfoil, which is conducive to the generation of smaller waves when the front hydrofoil 2 and the rear hydrofoil 10 work on the water surface. ° Angle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com