Cherry express whole course cold chain process

A whole-process cold chain and cherry technology, which is applied to household refrigeration devices, containers, packaging items, etc., can solve problems such as loss of freshness, rot, and fruitless grading, and achieve the effect of reducing extrusion damage and delaying working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

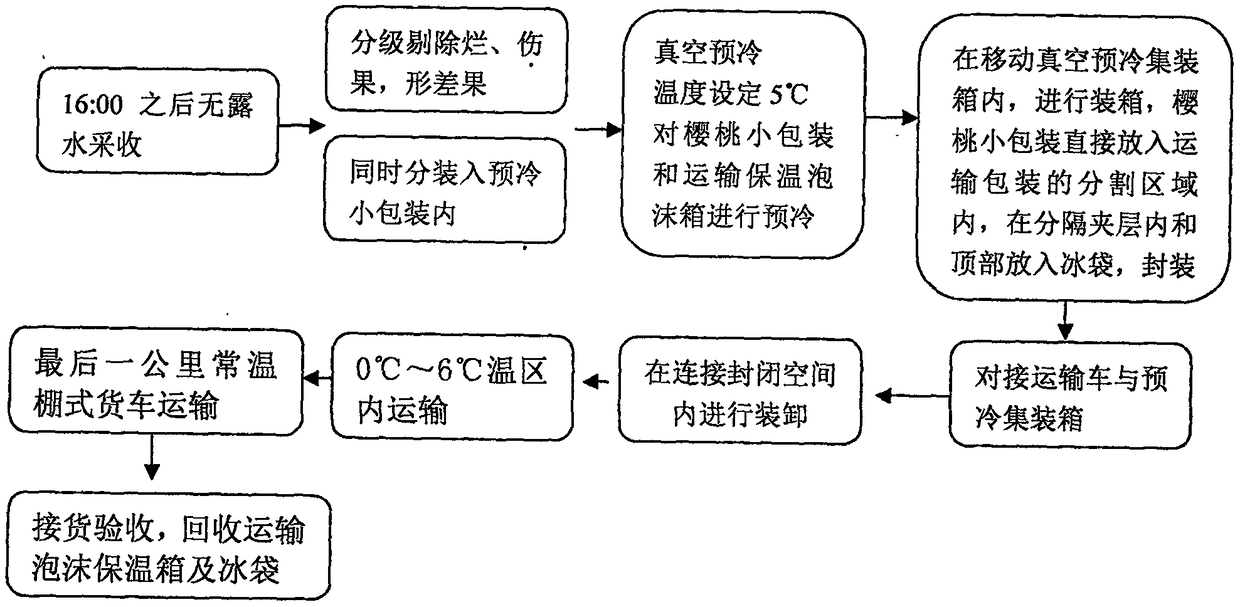

[0013] Combine below figure 1 Specific embodiments of the present invention are described in detail.

[0014] like figure 1 As shown, a kind of whole-process cold chain process of cherries is as follows:

[0015] 1. harvest

[0016] Studies have shown that the best time for fruit harvesting is no dew before 8:00 am and no dew after 16:00 pm. The harvesting time period of this process is set at 16:00 in the afternoon without dew. At this time, the atmospheric temperature is relatively low. During the working hours of the subsequent process, the temperature is on a downward trend. There is less heat in the field and the respiratory intensity is relatively reduced. Subsequent processes address energy conservation issues.

[0017] 2. Grading, packaging, pre-cooling

[0018] After the cherries are detached from the plants, with field heat, the respiration and transpiration are still relatively strong. If not controlled in time, the cherries will lose water, lose freshness and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com