Train station intelligent train loading system

A fire loading station and intelligent technology, applied in loading/unloading, transportation and packaging, conveyor control devices, etc., can solve the problems of low automation, low loading efficiency, and high labor intensity of staff, so as to reduce labor intensity, The effect of improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

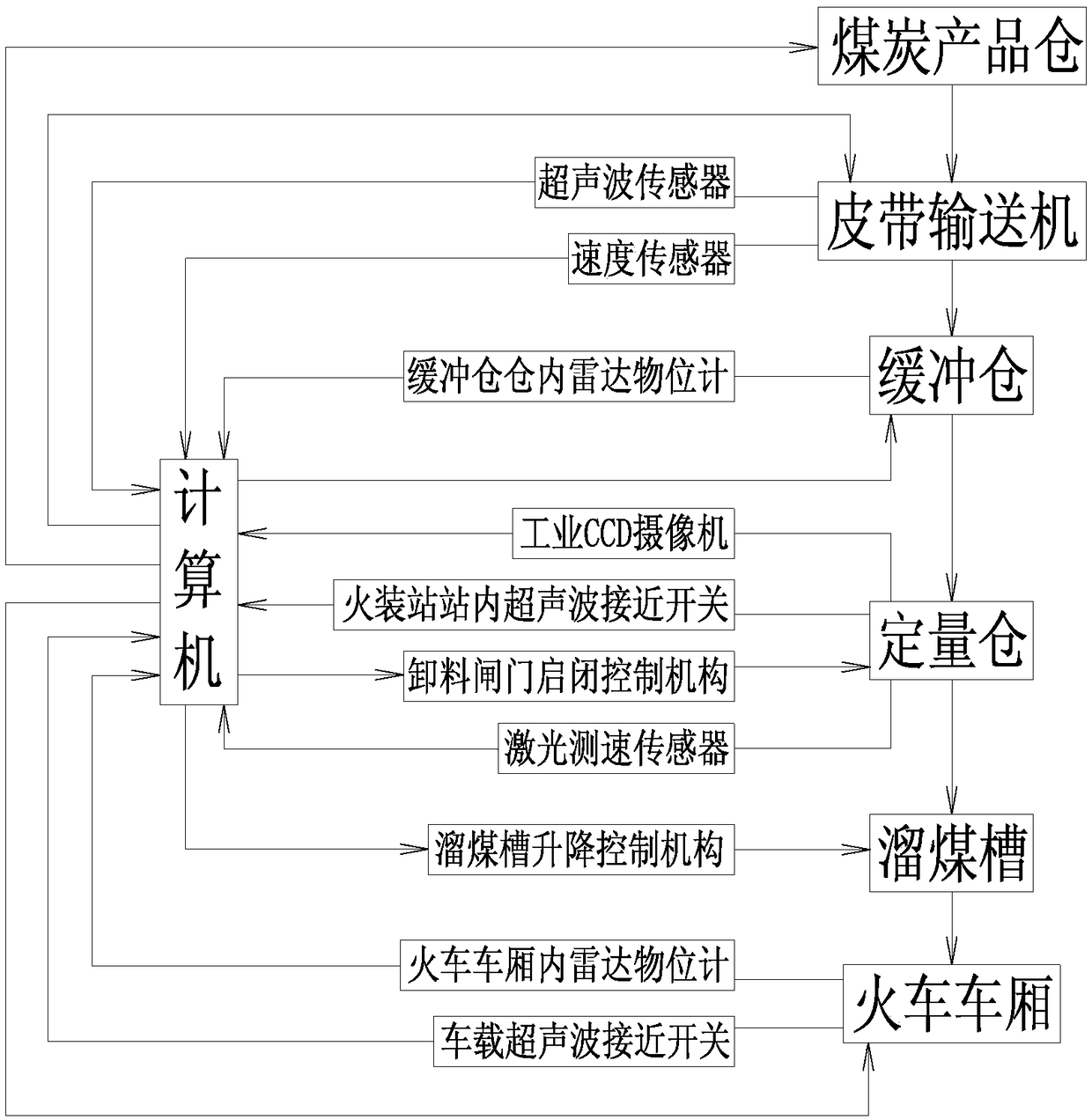

[0017] Such as figure 1 As shown, a kind of intelligent loading system of fire loading station includes a belt conveyor, a buffer bin, a quantitative bin, a coal chute and a computer; One end is connected to the inlet of the buffer bin; the buffer bin, quantitative bin and coal chute are arranged sequentially from top to bottom; the inlet of the buffer bin is located at the top of the bin body, and the outlet of the buffer bin is located at the top of the bin body bottom, and there are two outlets of the buffer bin, both of which are provided with discharge gates; the inlet of the quantitative bin is located at the top of the bin body, and the inlet of the quantitative bin is located at the outlet of the buffer bin. Directly below the feed port; the discharge port of the quantitative warehouse is located at the bottom of the warehous...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap