Aerial work equipment navigation positioning device, positioning method and aerial work equipment

A high-altitude operation, navigation and positioning technology, applied in the field of positioning and navigation, can solve the problems of inaccurate positioning of the working platform, low operation efficiency, complex positioning technology, etc., and achieve the effect of convenient operation, convenient and flexible operation, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

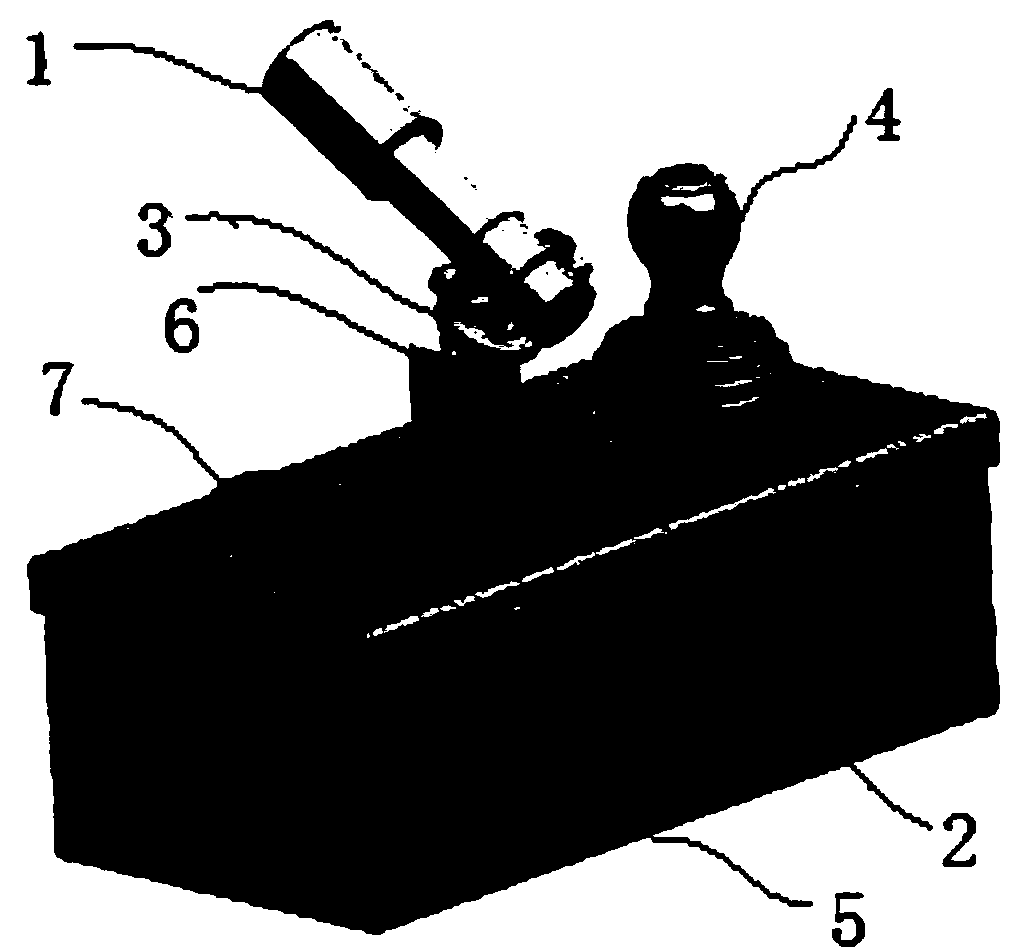

[0064] Such as Figure 1~2 As shown, this embodiment provides a navigation and positioning device for empty working equipment, including:

[0065] Set the positioning beam generator on the working platform to emit visible light to the target point in any range of 360°;

[0066] A three-axis position sensor is set to detect the angle information of the positioning beam generator in the three directions of X, Y, and Z;

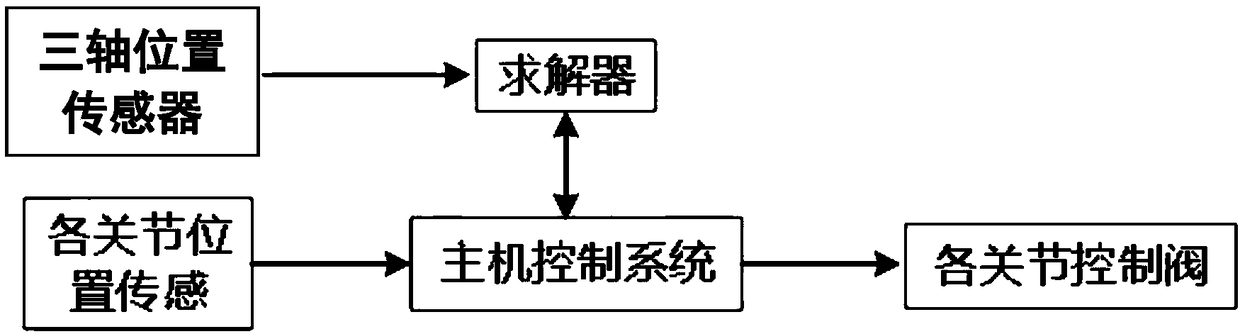

[0067] Set up the solver to obtain the angle information of the positioning beam generator in the X, Y, and Z directions and the position information of each joint on the aerial work equipment, and then solve the motion direction, motion range, speed and direction deviation data of each joint, and control the joint The motion data is sent to the host control system of aerial work equipment;

[0068] The host control system controls each joint to move the working platform to the target point according to the beam direction according to the control parameters gi...

Embodiment 2

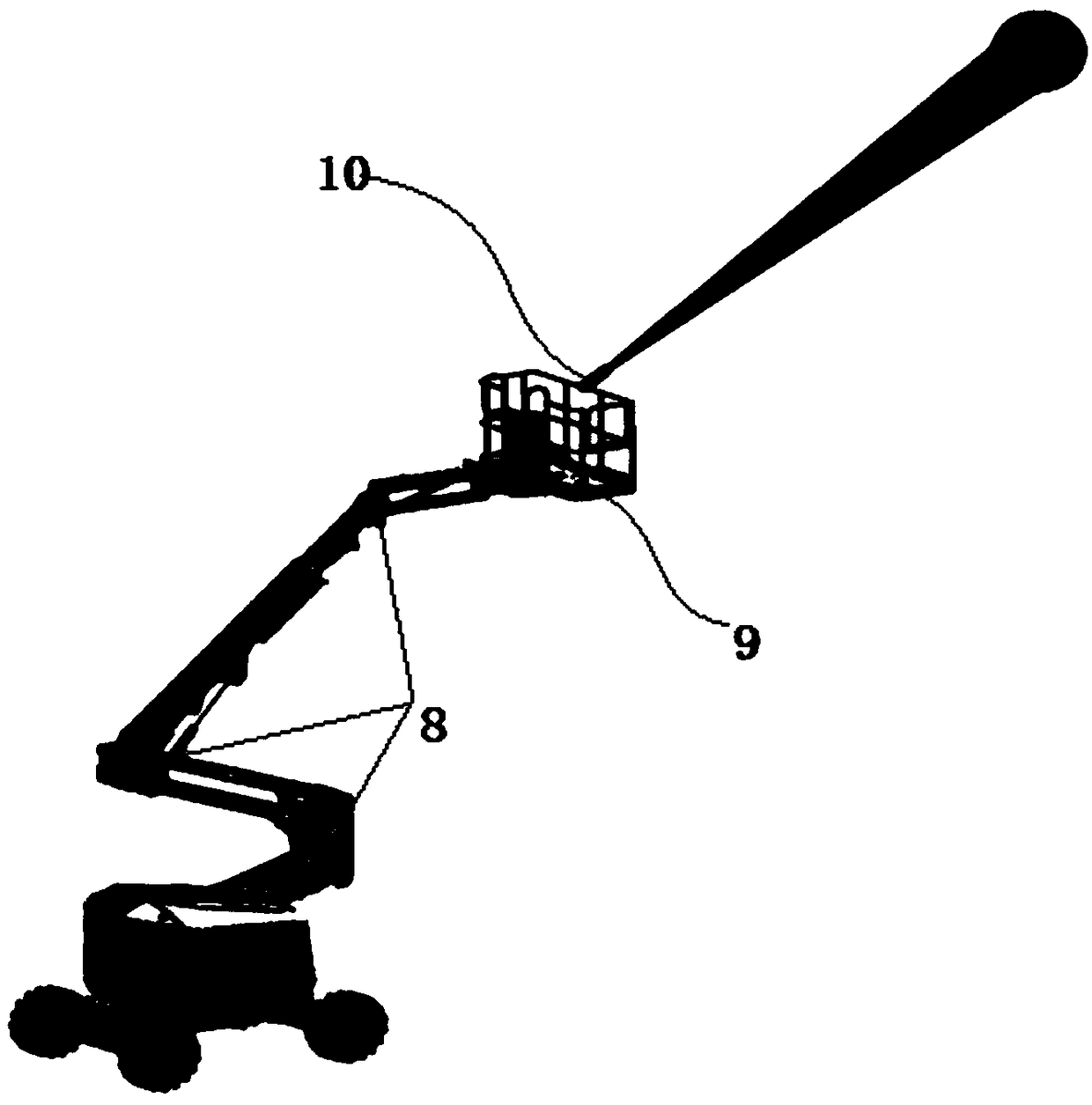

[0115] This embodiment is basically the same as Embodiment 1, except that the aerial work equipment in this embodiment is a straight-arm aerial work platform. Therefore, the position sensors of each joint do not include the angle sensor of the tower arm. Accordingly, the motion direction, range of motion, speed and direction deviation data of each joint described in the corresponding steps are solved as follows:

[0116]

[0117] The above equations are used to determine the range of motion and direction of motion of each movable joint, where,

[0118] Turntable offset, positive means right rotation, negative means left rotation; α 0 : Indicates the initial angle of the turntable;

[0119] Main arm offset, positive means the main arm rises, negative means the main arm falls; γ 0 : indicates the initial angle of the main arm;

[0120] Flying arm offset, positive means the flying arm is rising, negative means the flying arm is falling; δ 0 : Indicates the initial an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap