Fermentation device for feed

A technology for fermentation device and feed, which is applied in specific-purpose bioreactor/fermenter, feed, biochemical cleaning device, etc., can solve the problems of low one-time output, insufficient fermentation, high labor cost and equipment input cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below.

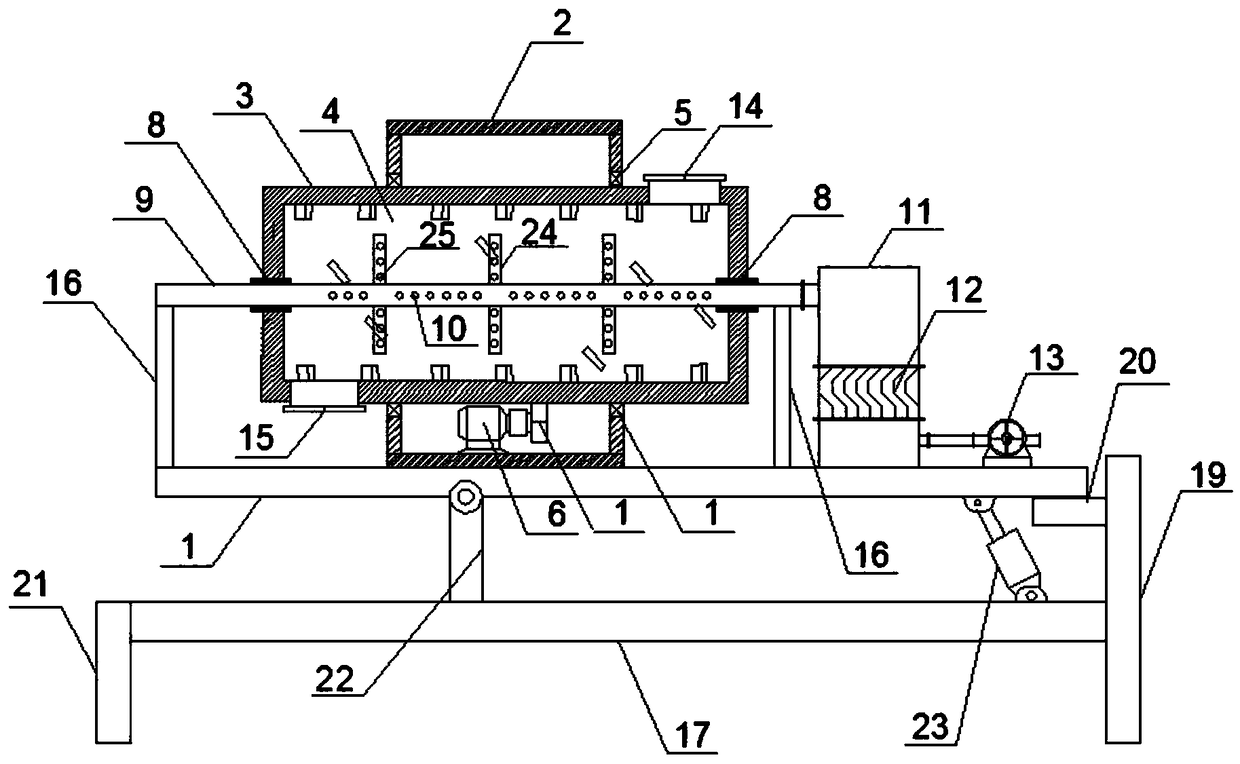

[0014] Such as figure 1 As shown, a fermenting device for feed includes a support cylinder 2 arranged on a working platform 1, and a rotating cylinder 3 with a cavity inside is provided inside the support cylinder 2, and the support cylinder 2 The left and right end plates of the two through holes are correspondingly provided with two through holes a4, and the positions corresponding to the two through holes on the left and right parts of the support cylinder 2 pass through the bearing 5 and the upper and lower end plates of the rotating cylinder 3 respectively. connect;

[0015] The inside of the supporting cylinder 2 and the lower end of the rotating cylinder 3 are provided with a geared motor 6, the output shaft of the geared motor 6 is connected to the friction roller 7, and the friction roller 7 is in contact with the lower end surface of the rotating cylinder 3, and the friction roller 7 drives the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com