Glue sticking component and glue sticking device

A technology for sticking devices and components, which is applied to electrical components, structural parts, electrodes of primary batteries, etc., can solve the problems of large area occupied by the structure, and achieve the effect of improving efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

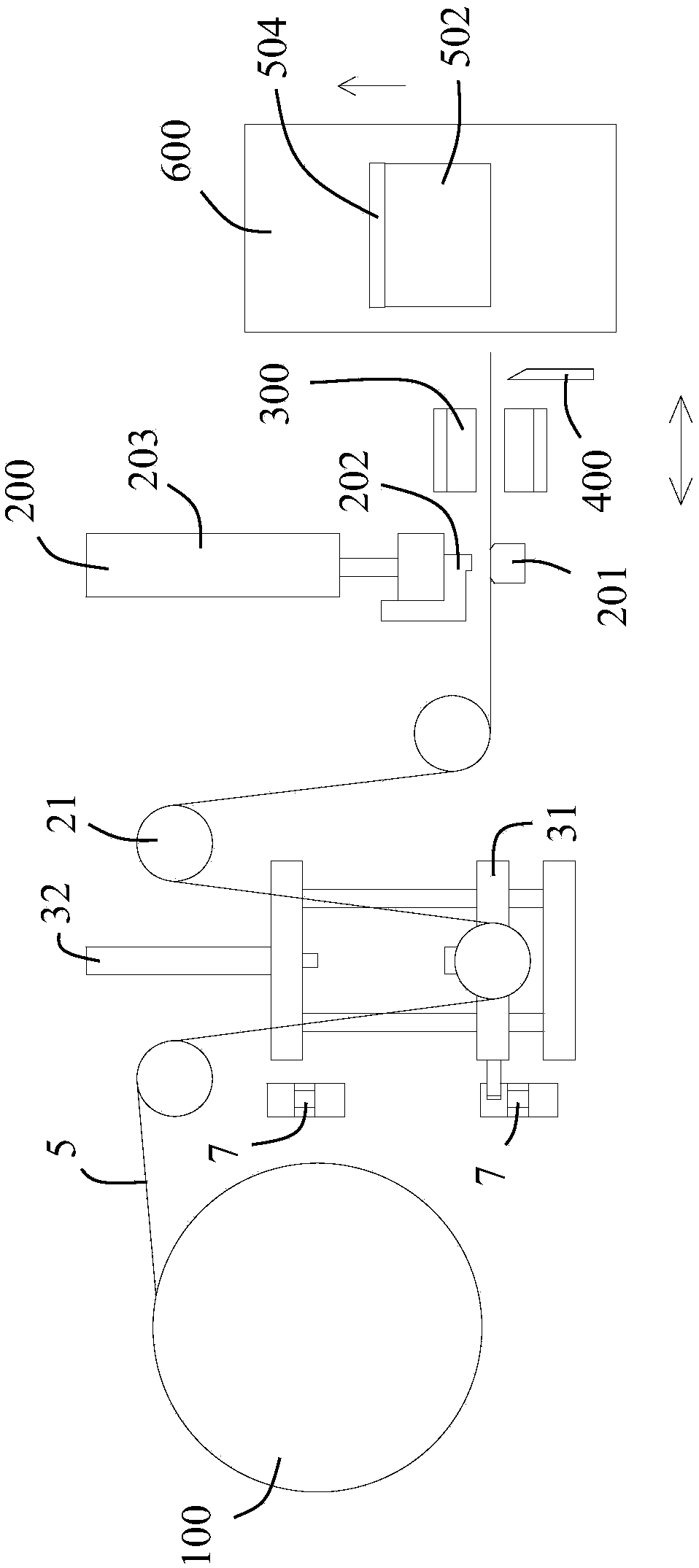

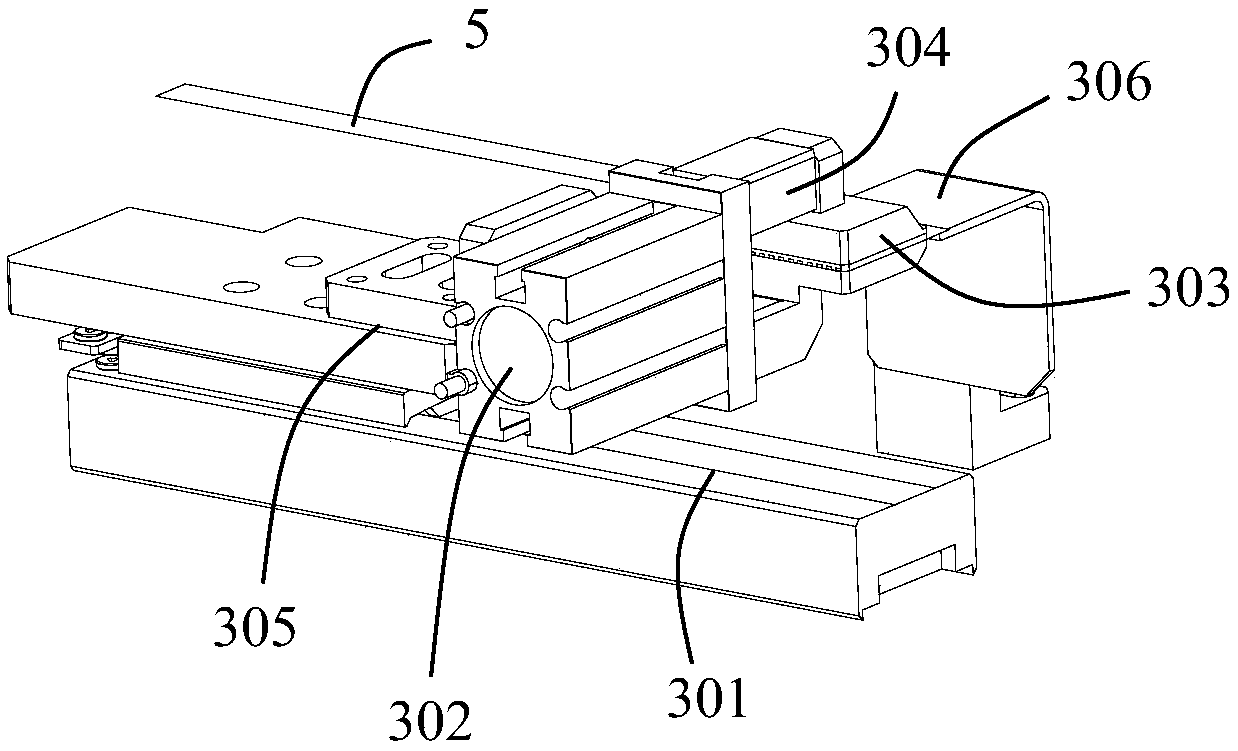

[0021] Please refer to figure 1 As shown, the present invention discloses a gluing device, which includes an unwinding mechanism 100 for unwinding the tape 5, a platen assembly 200 for pressing the tape 5, a jaw assembly 300 for clamping the tape 5, A cutting device 400 and an adhesive assembly 500 for cutting the adhesive tape 5 . In the illustrated embodiment of the present invention, the glue sticking assembly 500 is used to stick the cut tape 5 on the pole piece 600 along with the transmission of the pole piece 600 .

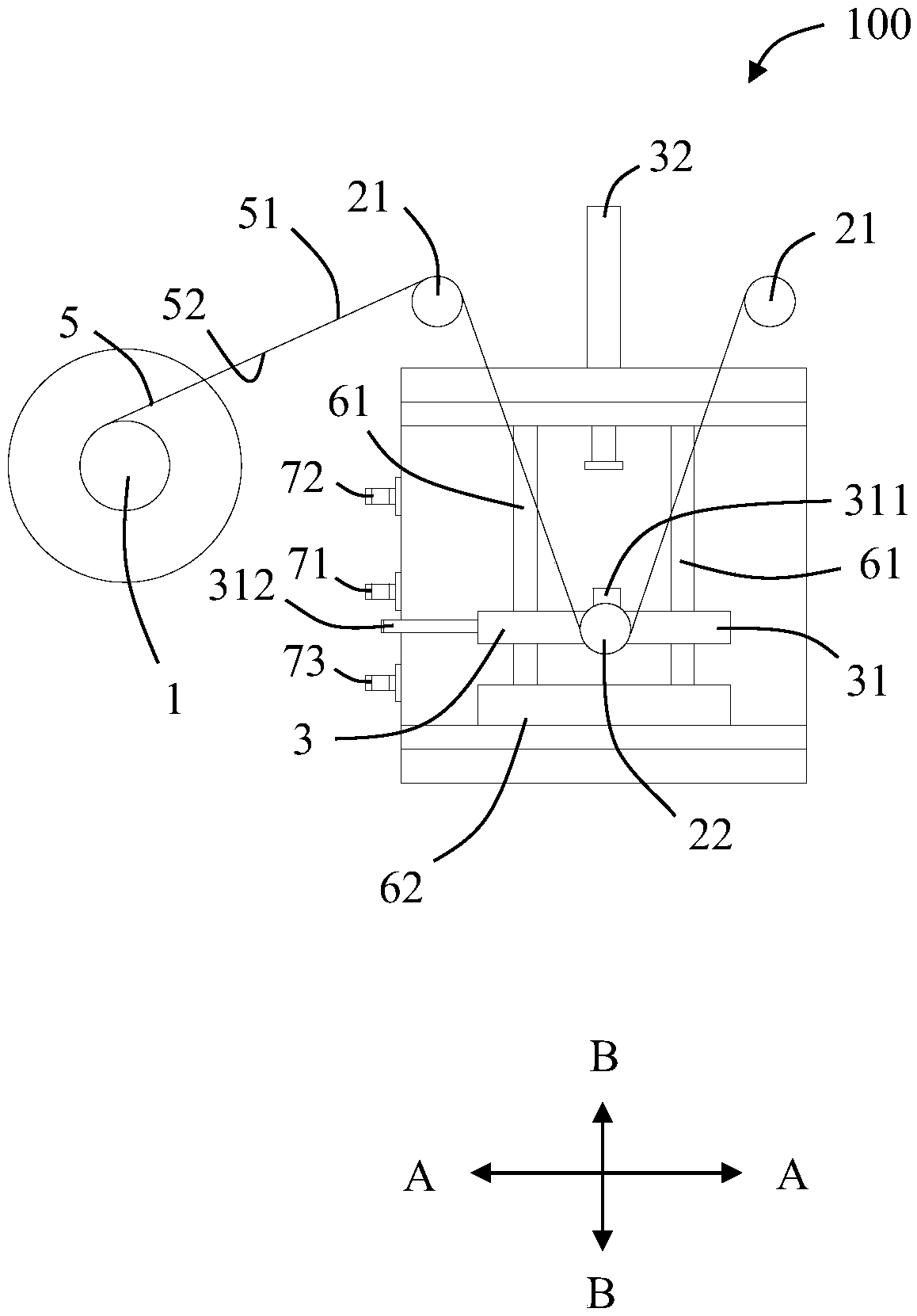

[0022] Please refer to figure 2 As shown, the unwinding mechanism 100 includes an unwinding shaft 1 , a rotating shaft group for conveying the adhesive tape 5 and a buffer device 3 for buffering the adhesive tape 5 . Those skilled in the art can understand that the so-called "caching" refers to not directly feeding the adhesive tape 5 on the unwinding reel 1, but first pulling the adhesive tape 5 on the unwinding reel 1 to a predetermined length to a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com