Bamboo salt calcining furnace and preparation method for preparing bamboo salt having high-reduction potential

A calciner and bamboo salt technology, applied in the field of condiment preparation, can solve the problems of high labor intensity, no scientific detection index, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

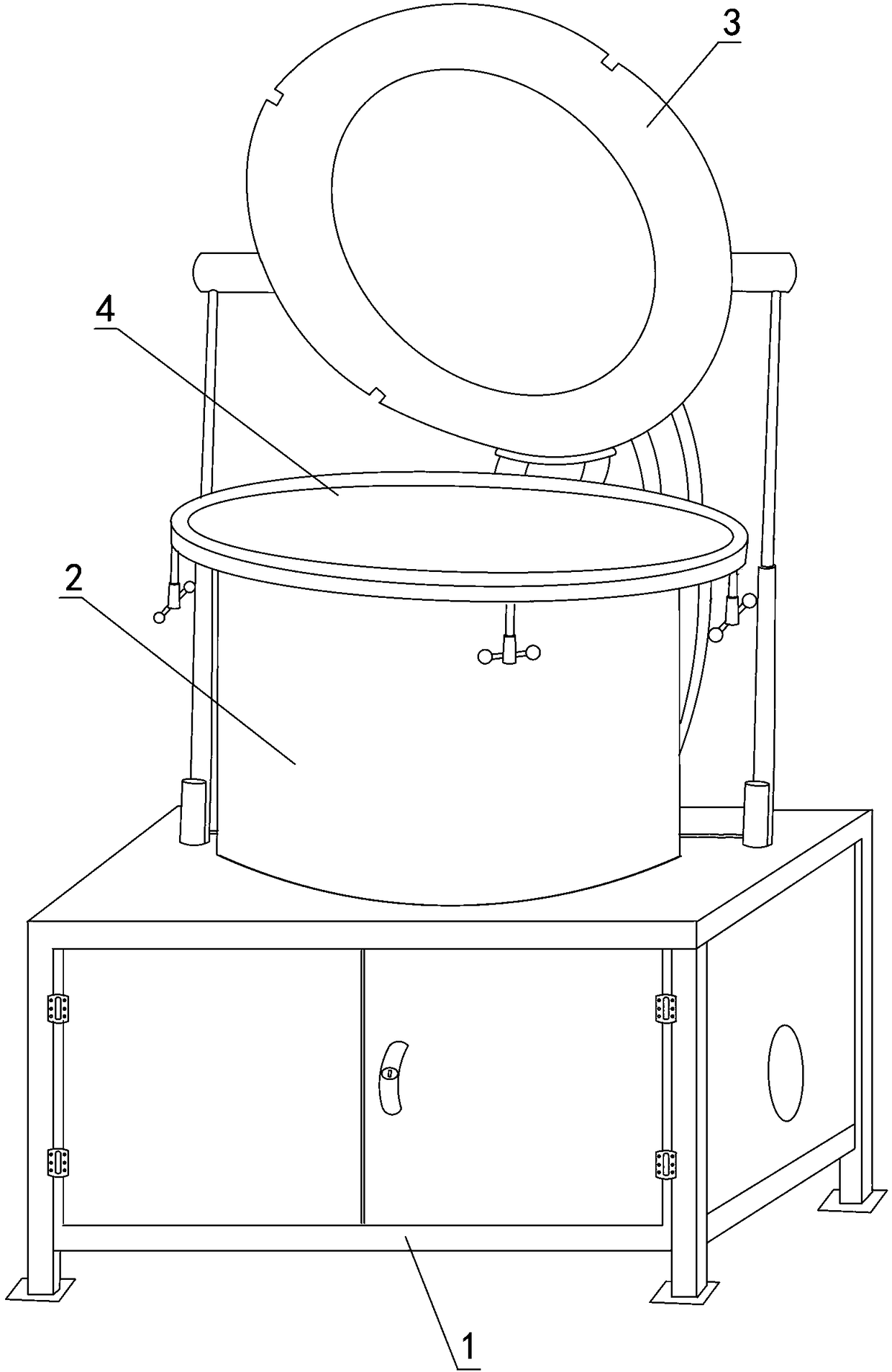

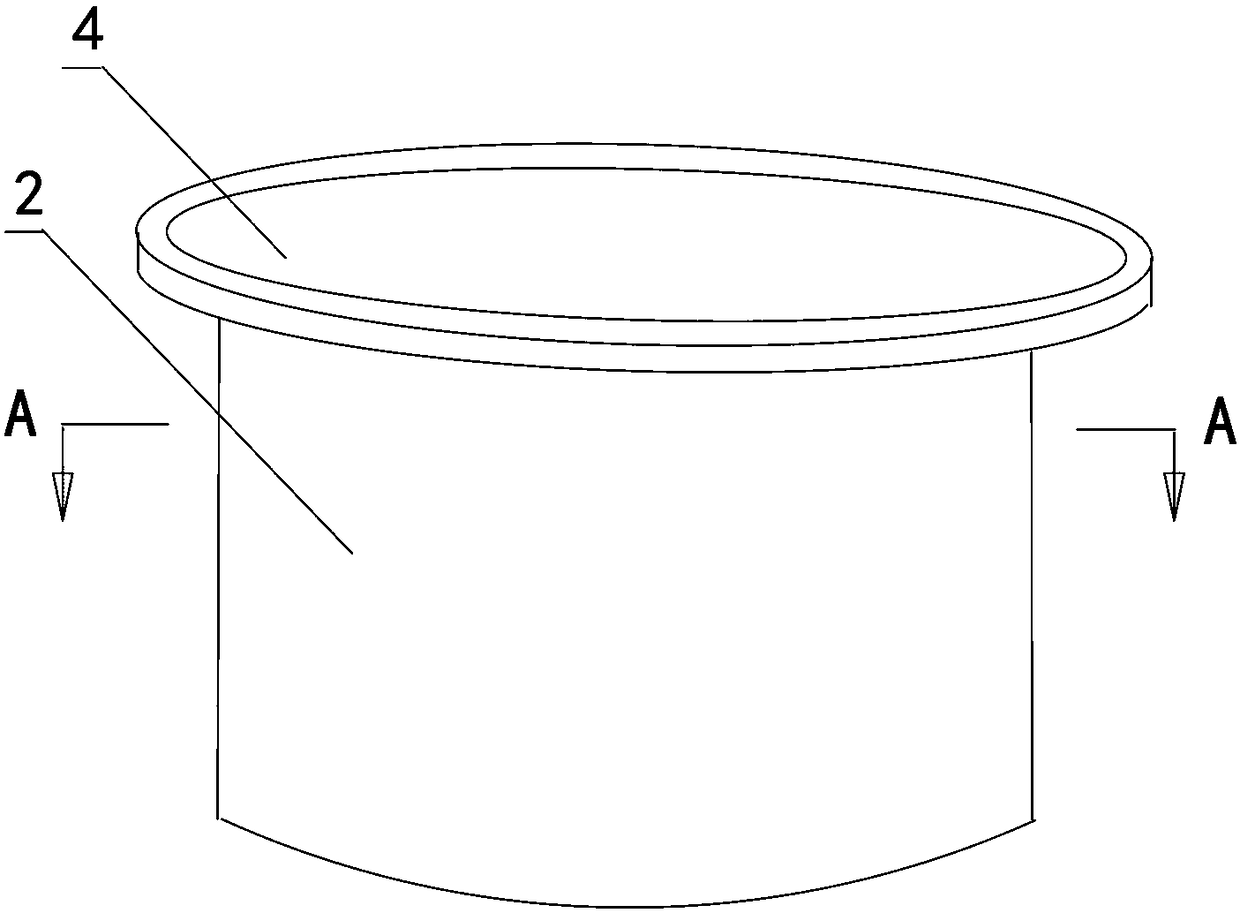

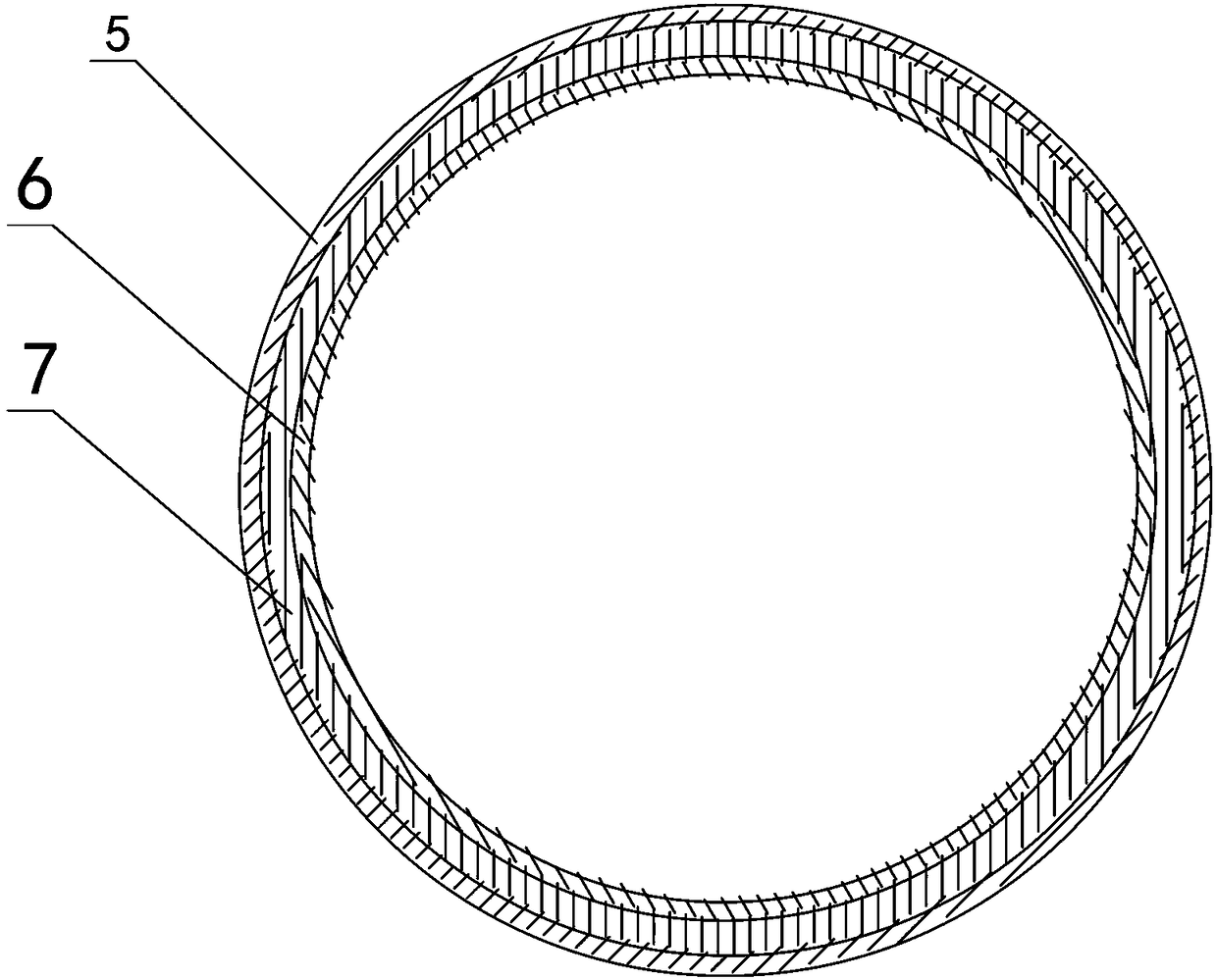

[0030] Such as figure 1 , figure 2 and image 3 As shown, the present invention prepares the bamboo salt calciner with high reduction potential bamboo salt, and is made up of heating base 1 and the furnace body 2 that is installed on the heating base 1, and furnace body 2 comprises furnace cover 3, calcining chamber 4 and furnace body wall , the furnace wall has a three-layer structure, the inner layer is a refractory material layer 7, and the refractory material layer 7 refers to a conventional high-temperature-resistant commercial refractory brick, and the outer layer is a furnace shell layer 5, which is made of metal materials. An interlayer is formed between the shell layers 5 of the furnace body, and a tourmaline layer 7 is arranged in the interlayer. The thickness of the tourmaline layer 7 is 1-5 mm. After crushing the commercial tourmaline into fine powder of 100-200 mesh, mix it evenly with the binder, adjust the viscosity with water, and apply it in the interlayer ...

Embodiment 2

[0032] The present invention prepares the concrete technical steps of the method for bamboo salt with high reduction potential:

[0033] (1) Take 10 kg of dry bamboo leaves and 40 kg of dry bamboo, crush the bamboo, and crush them together with the bamboo leaves in a crushing device into coarse particles with a particle size of 1-3 mm to obtain coarse bamboo particles for later use:

[0034] (2) Take 500 kg of edible salt and coarse bamboo grains and mix them evenly to obtain a bamboo salt mixture for later use:

[0035] (3) Take the bamboo salt mixture and place it in the bamboo salt calciner described in Example 1 for calcining, raise the temperature in the calcining chamber of the bamboo salt calciner to 700°C within 2 hours, calcinate at this temperature for 6 hours, and cool. Take it out and crush it.

[0036] (4) After testing, the reduction potential of the obtained bamboo salt was -70 millivolts. The pH value is 9.0.

Embodiment 3

[0038] (1) Take 10 kg of dry bamboo leaves and 40 kg of dry bamboo, crush the bamboo, and crush them together with the bamboo leaves in a crushing device into coarse particles with a particle size of 1-3 mm to obtain coarse bamboo particles for later use:

[0039] (2) Take 500 kg of edible salt and coarse bamboo grains and mix them evenly to obtain a bamboo salt mixture for later use:

[0040] (3) Take the bamboo salt mixture and place it in the bamboo salt calciner described in Example 1 for calcining, raise the temperature in the calcining chamber of the bamboo salt calciner to 800°C within 2 hours, calcinate at this temperature for 8 hours, and cool. Take it out and crush it.

[0041] (4) After testing, the reduction potential of the obtained bamboo salt was -300 millivolts. The pH value is 9.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com