Rice huller

A rice husker and paddy technology, which is applied in grain finishing, grain processing, and grain milling, etc. It can solve problems such as easy generation of dust, inability to adjust the tightness of the tension belt, and unclean paddy filtration, so as to avoid dust pollution Environment, avoiding the effect of iron impurities from damaging the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

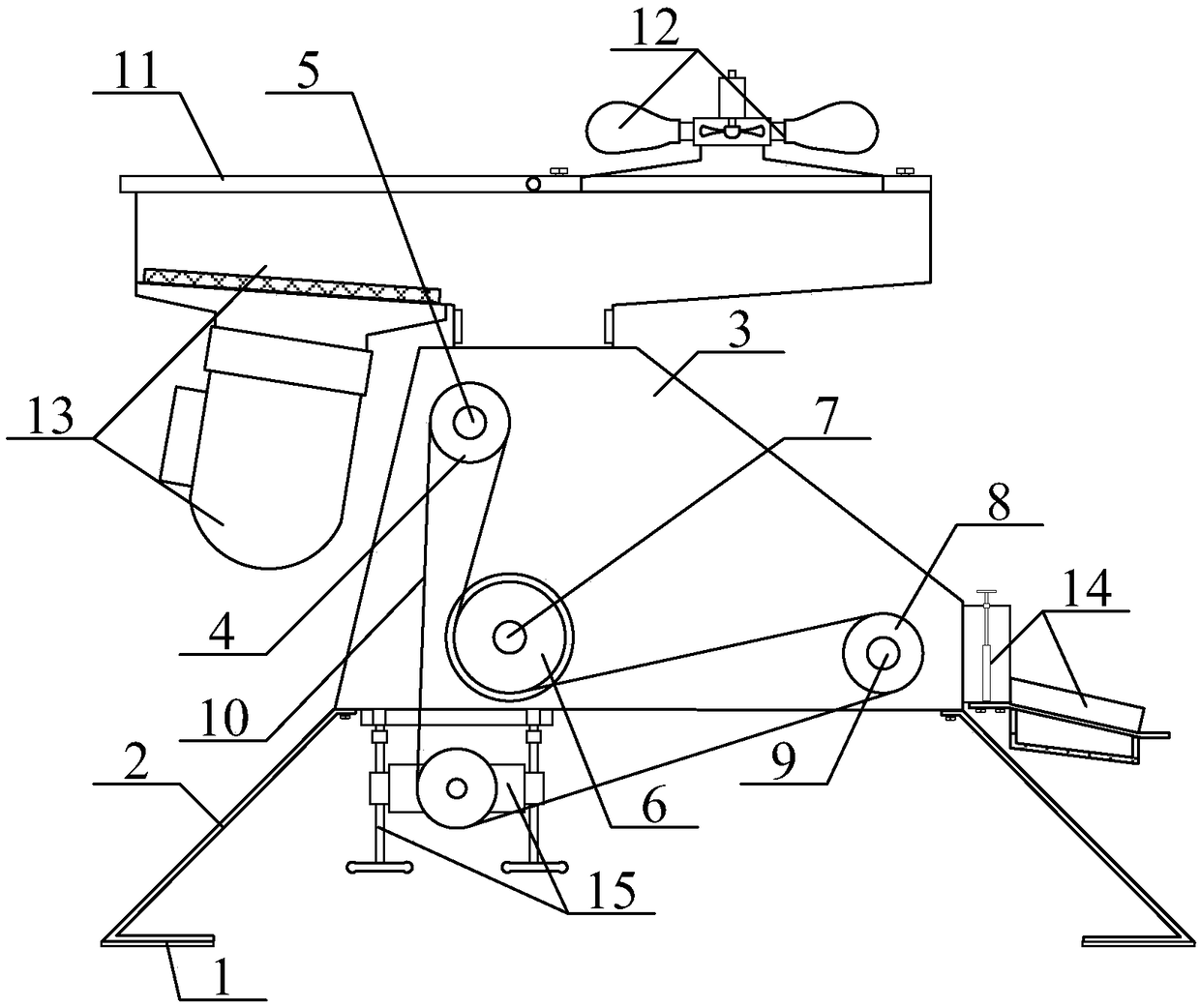

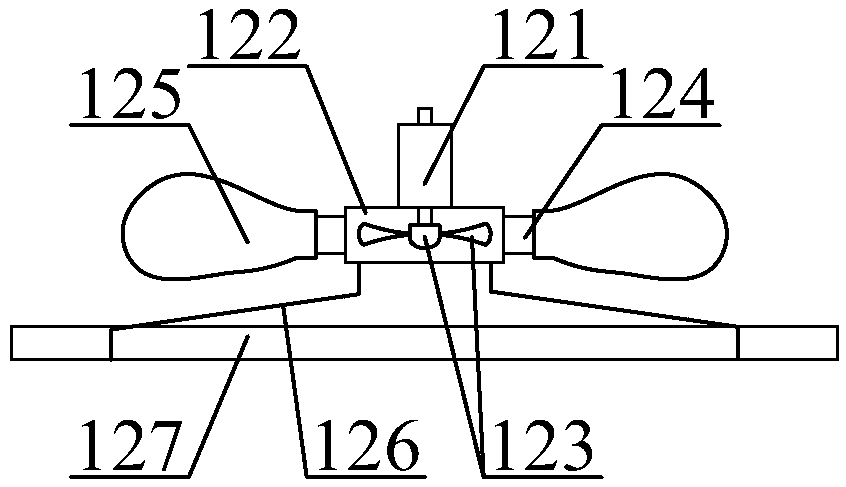

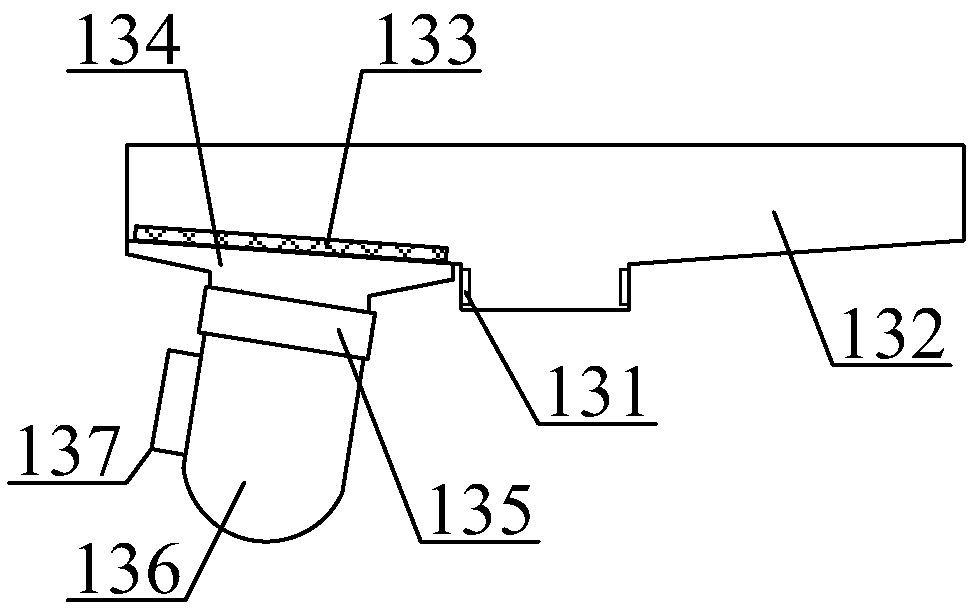

[0057] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a rice huller includes anti-slip foot pads 1, supporting legs 2, head body 3, fast roller wheel 4, fast roller shaft 5, slow roller flat wheel 6, slow roller shaft 7 that can move in an arc, auxiliary Wheel 8, auxiliary shaft 9, V-belt 10, feed cover 11, paddy dust anti-splash adsorption processor 12 during husking, paddy impurity debris filter adsorption hopper structure before husking 13, dust fine impurities final filter after husking is exported Plate structure 14 and belt tightness can be adjusted power machine 15, and described anti-skid foot pad 1 is glued on the bottom of supporting leg 2 transversely; The fast roller wheel 4 is installed on the upper left corner of the front part of the machine head body 3 through the fast roller shaft 5; The auxiliary wheel 8 is installed on the front lower right corner of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com